Etching technique for preparing ultrathin flexible silicon sustrate through two step method in wet-process etching

A wet etching, silicon substrate technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as uneven corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Imported flexible silicon substrate (SOI) film is prepared by oxygen ion implantation isolation technology, p-type, (100) crystal plane.

[0041] Degreasing treatment: Boil in trichlorethylene-acetone-absolute ethanol for 10-20 minutes in sequence, and wash with deionized water.

[0042] Hydrofluoric acid rinse: Soak in HF solution diluted with water for 10 seconds.

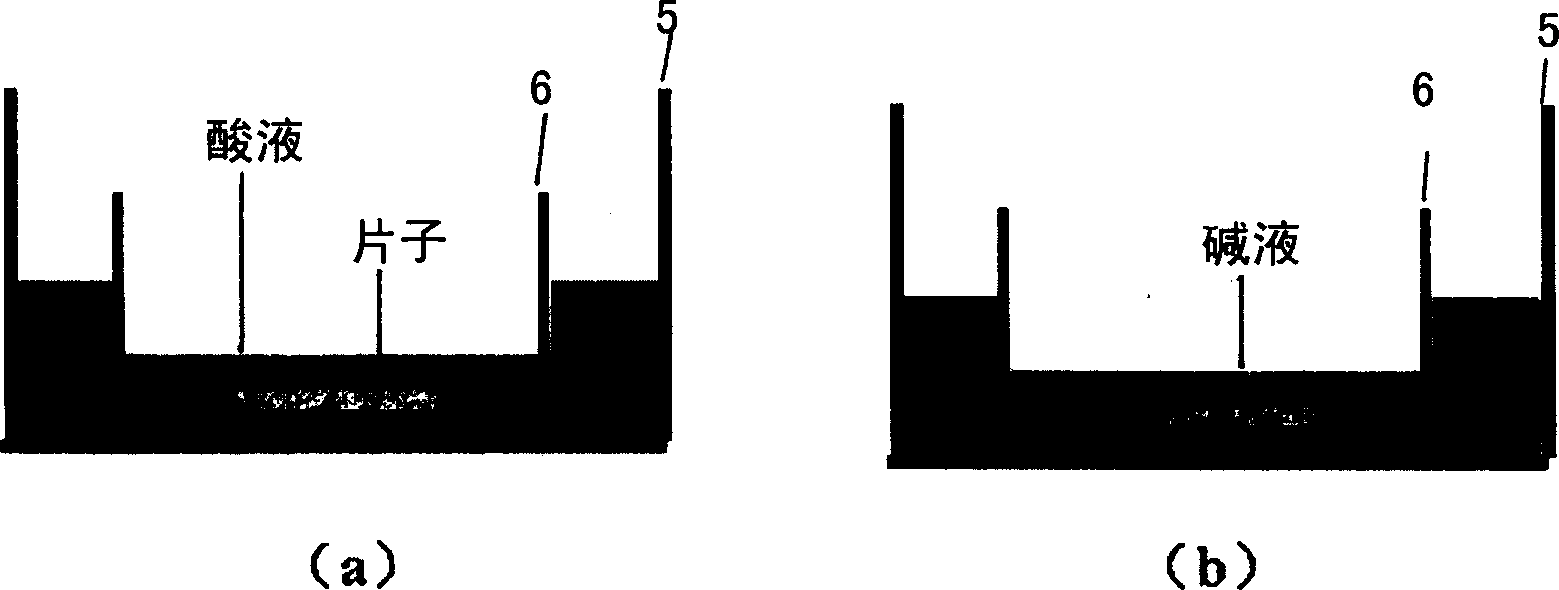

[0043] Acid corrosion: first in HNO 3 Boil in a medium water bath for 2 minutes, wash with deionized water; soak in HF solution for 10 seconds, wash with deionized water; repeat the above operation 3 times.

[0044] After cleaning with deionized water, alkaline etching is performed.

[0045] Alkaline corrosion: ratio, KOH / H 2 O=10g / 100ml (an appropriate amount of ethylene-propanol or n-butanol can be added), corrode at 35°C for 1.5min.

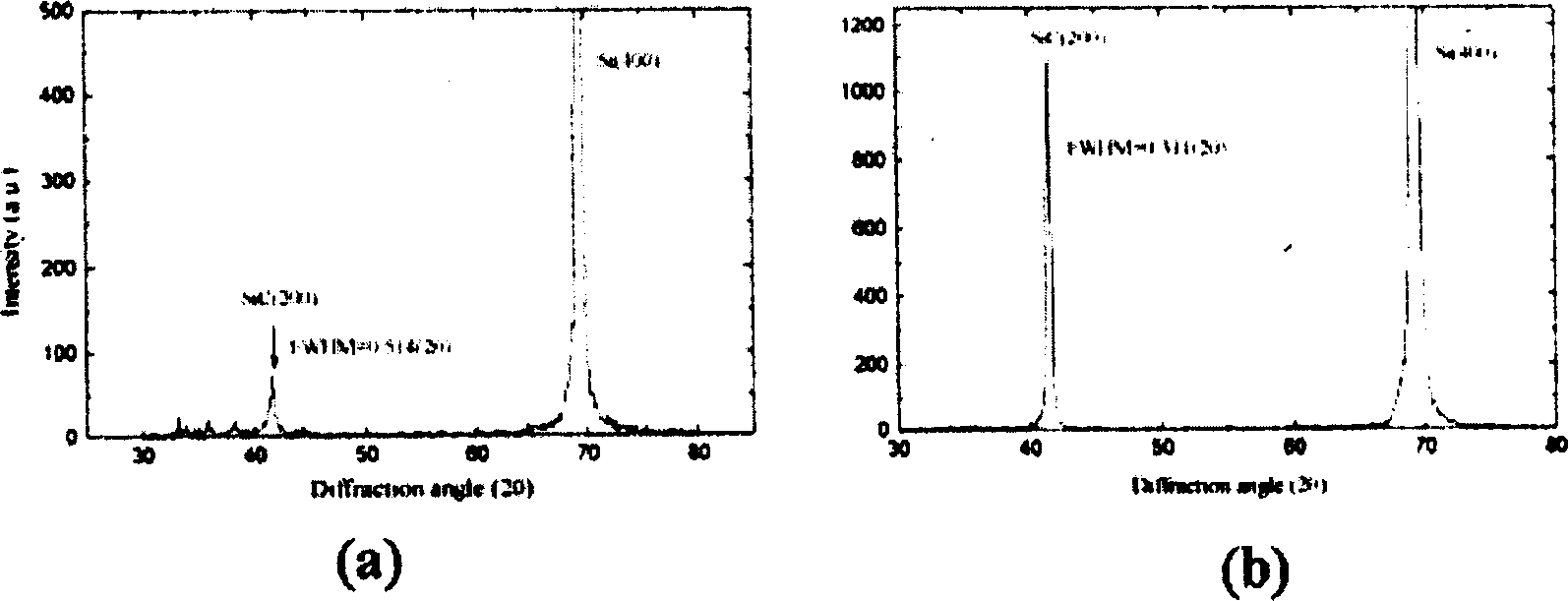

[0046] Under the interference effect of light, the corroded and thinned surface silicon presents a purple-red color with uniform luster (see figure 2 ), with a thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com