Dissecting process for diode device

A diode and device technology, applied in the field of anatomy of diode devices, can solve problems such as product chip corrosion, affect the dissection process, change chip shape, etc., to achieve the effects of avoiding damage, ensuring uniform corrosion, and speeding up the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

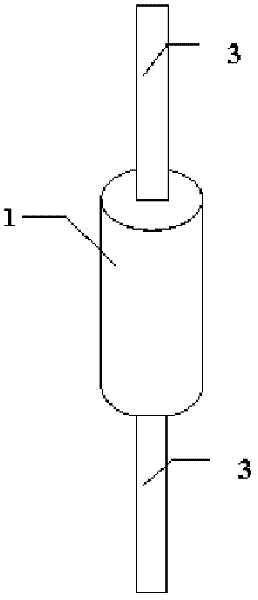

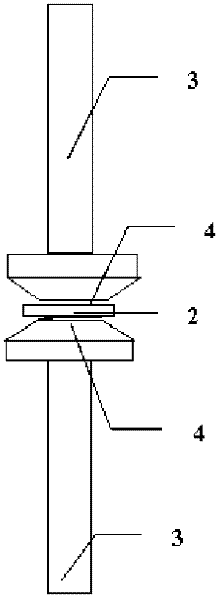

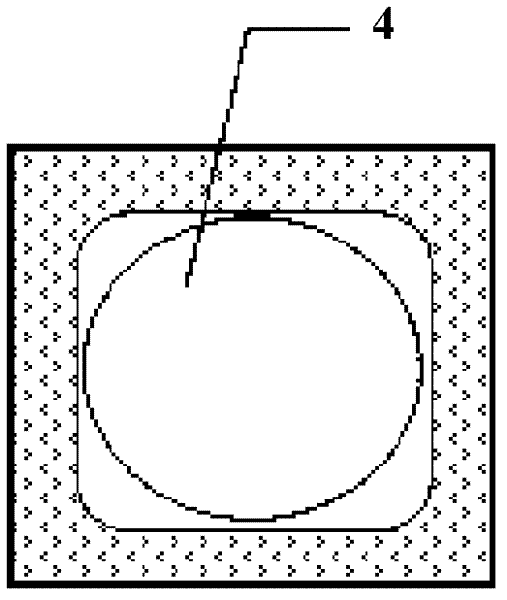

[0025] Embodiment: a kind of dissecting process that is used for diode device, as attached Figure 1-4 As shown, the diode device is composed of a diode chip 2 covered by epoxy resin 1, two copper leads 3 and a solder layer 4 between the surface of the diode chip 2 and the copper leads 3; it is characterized in that: the dissection process Include the following steps:

[0026] Step 1, the concentrated sulfuric acid that concentration in the beaker is 98% is heated to boiling;

[0027] Step 2, place the diode device in the beaker of the step 1, continue to heat, when the diode device exposes the side of the chip and part of the copper lead area, then remove the diode device from the beaker;

[0028] Step 3, place the diode device after step 2 in clear water, and then perform ultrasonic vibration cleaning, and remove the diode device from the clear water after the epoxy resin is removed;

[0029] Step 4. Place the diode device after step 3 in the acetone solution, which can br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com