A method for preparing ultra-high quality SOI-based bonded GE thin films

A bonding and quality technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to solve problems such as high-density threading dislocations and poor crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

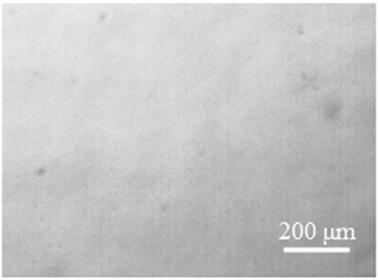

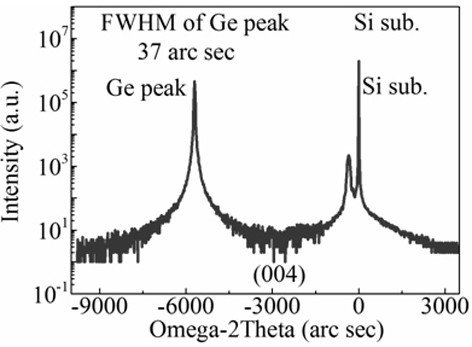

Image

Examples

Embodiment

[0025] 1. Surface treatment of SOI sheet and Ge sheet

[0026] 1) The SOI sheet and the Ge sheet were ultrasonically cleaned with acetone, ethanol, and deionized water for 10-15 min, respectively, to remove particles and organic matter attached to the surface of the substrate;

[0027] 2) Wash the SOI sheet after ultrasonic cleaning with H 2 SO 4 :H 2 o 2 =4:1 (v / v) solution was boiled for 10~15 min, rinsed with deionized water for 10~115 times, and then washed with HF:H 2 Soak in O=1:20 (v / v) solution for 2-4 minutes, rinse with deionized water for 10-15 times;

[0028] 3) Then the SOI sheet was coated with NH 4 OH:H 2 o 2 :H 2 The solution of O=1:1:4 (v / v / v) was boiled for 10-15 min, rinsed with deionized water for 10-15 times, and then washed with HF:H 2 Soak in O=1:20 (v / v) solution for 2-4 minutes, rinse with deionized water for 10-15 times;

[0029] 4) Finally, use HCl:H on the SOI sheet 2 o 2 :H 2 The solution of O=1:1:4 (v / v / v) was boiled for 10-15 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com