Patents

Literature

39results about How to "Slow corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Leaching system and leaching method for valuable metal in waste lithium battery

ActiveCN107863583AReduce concentrationThe reduction effect is stableWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionMetal leaching

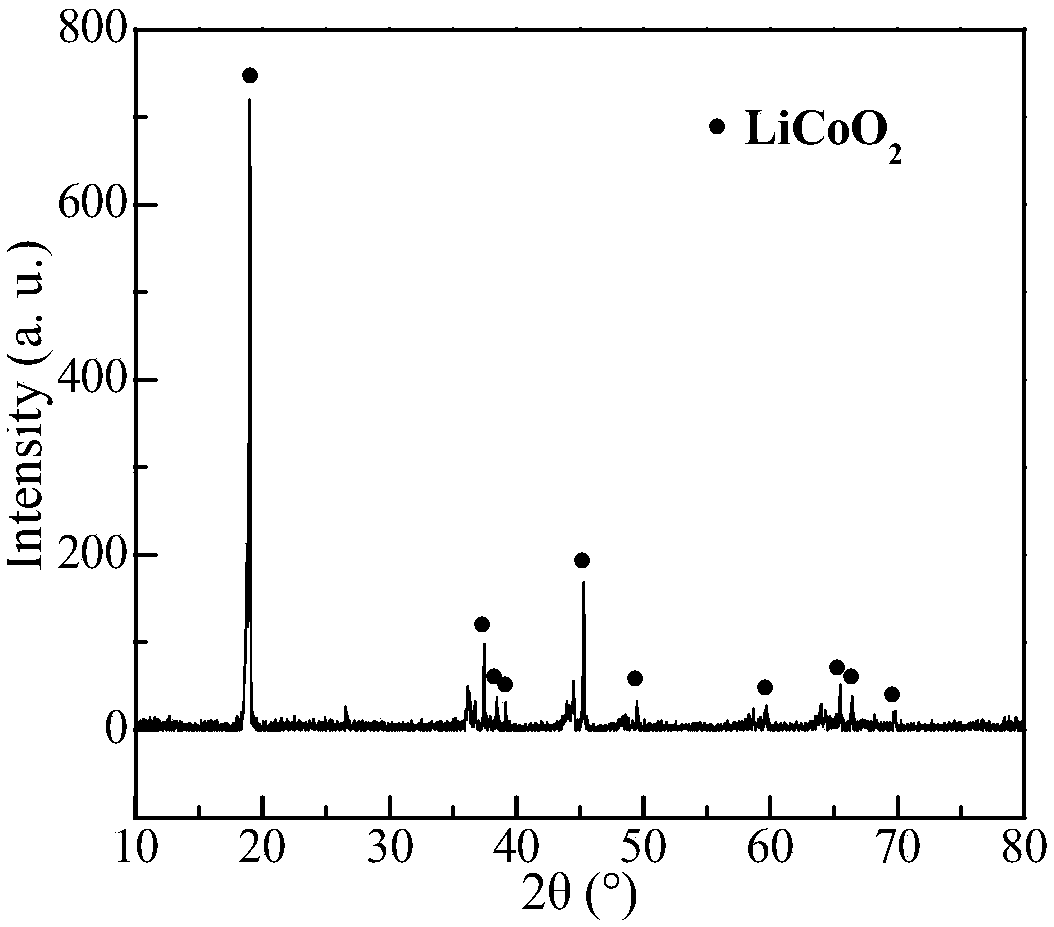

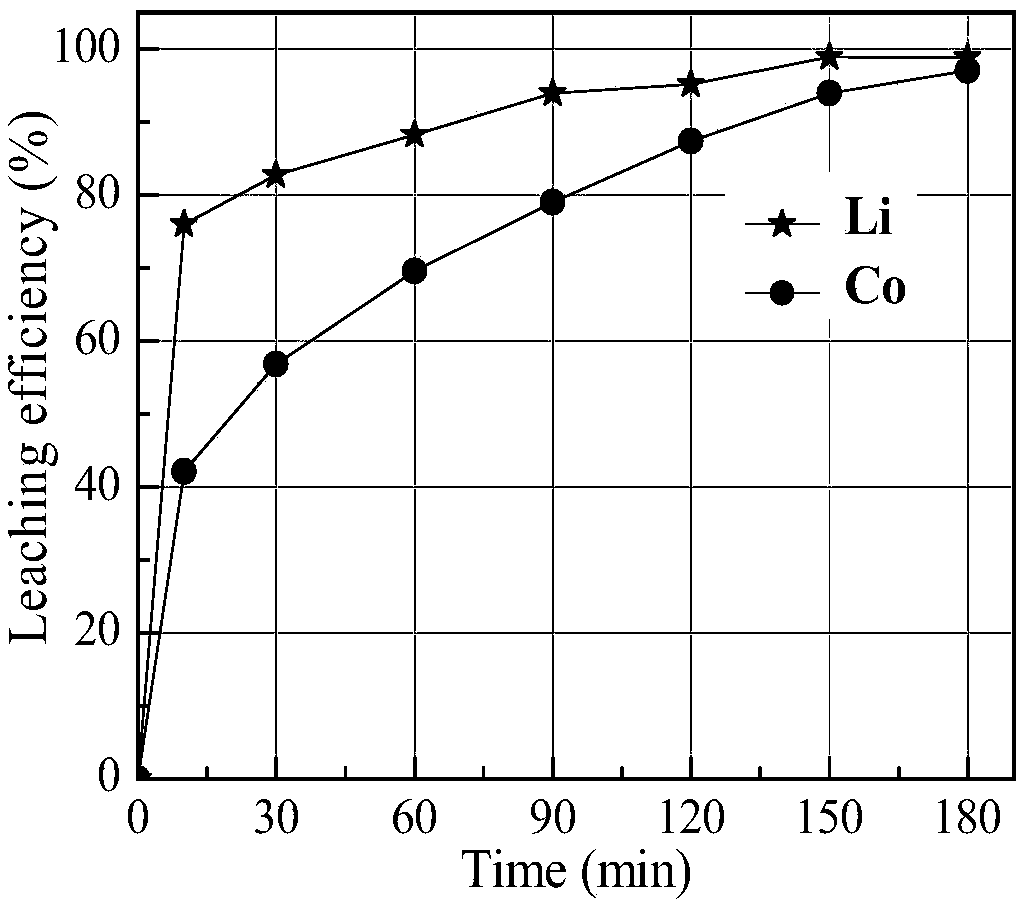

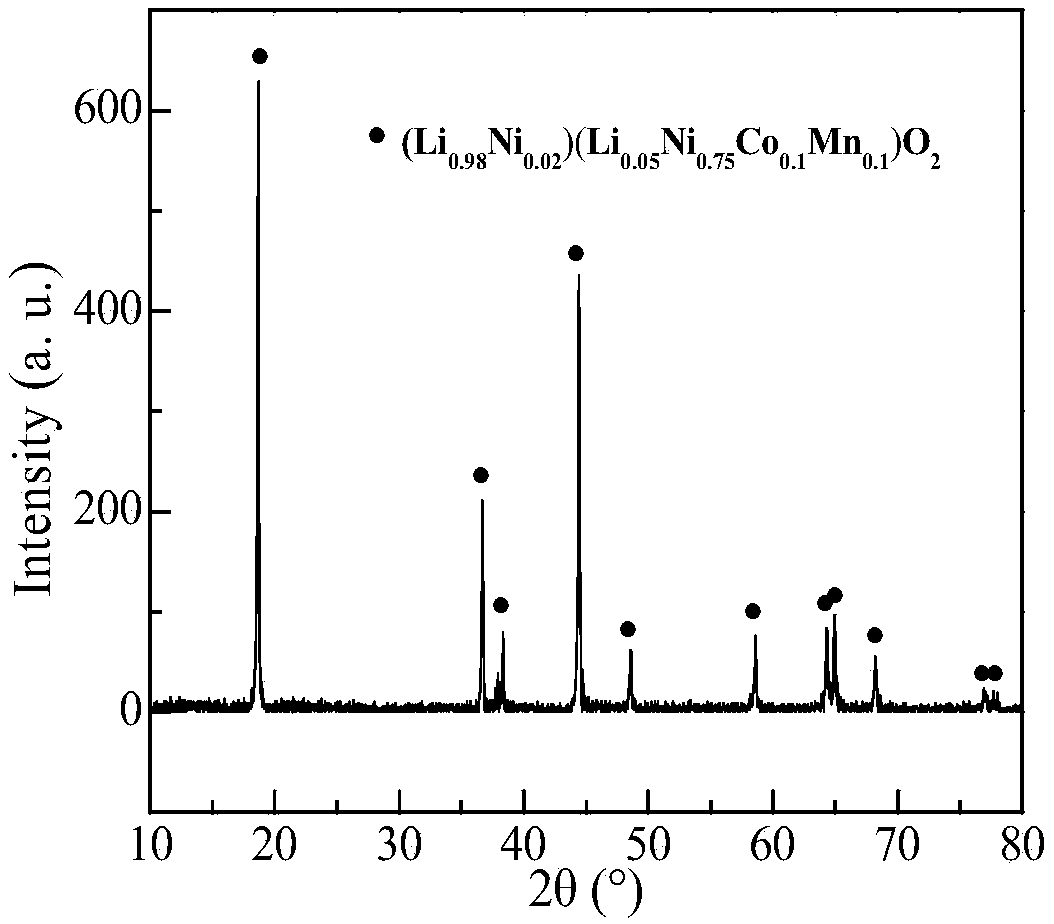

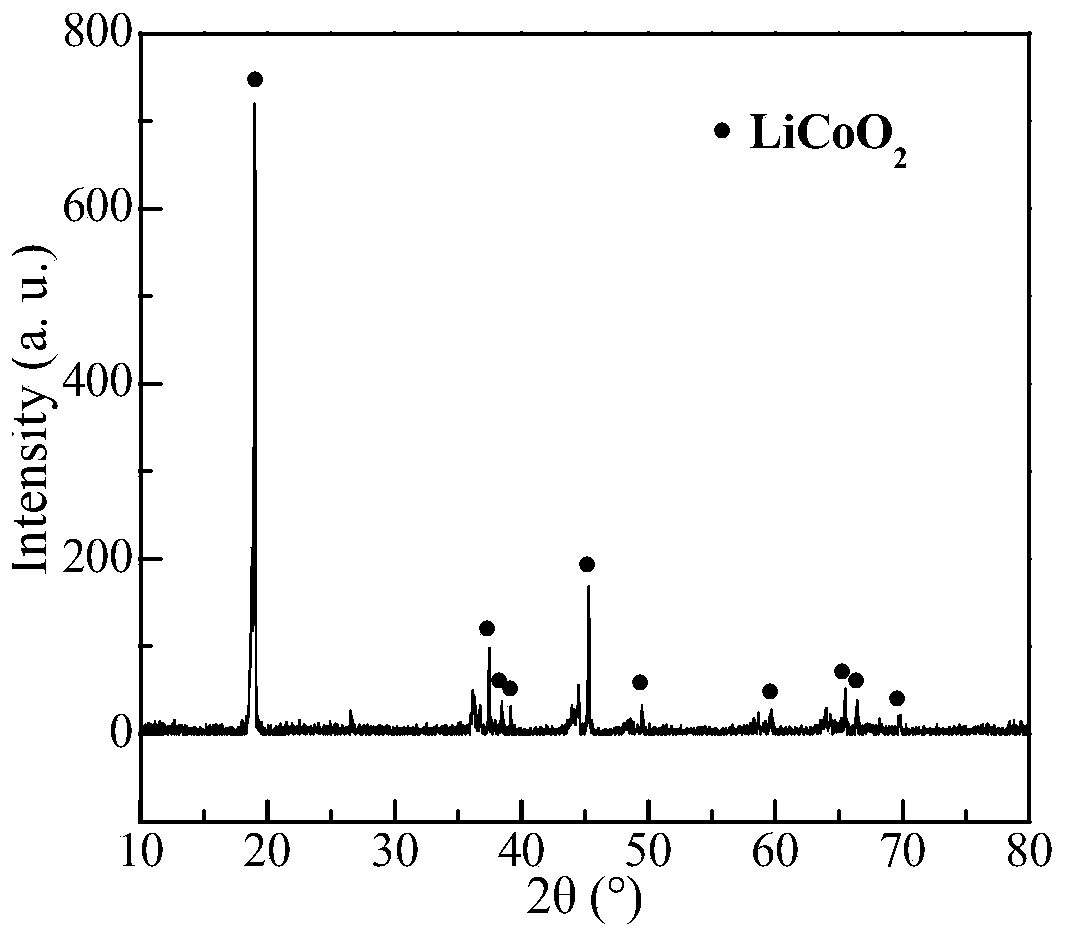

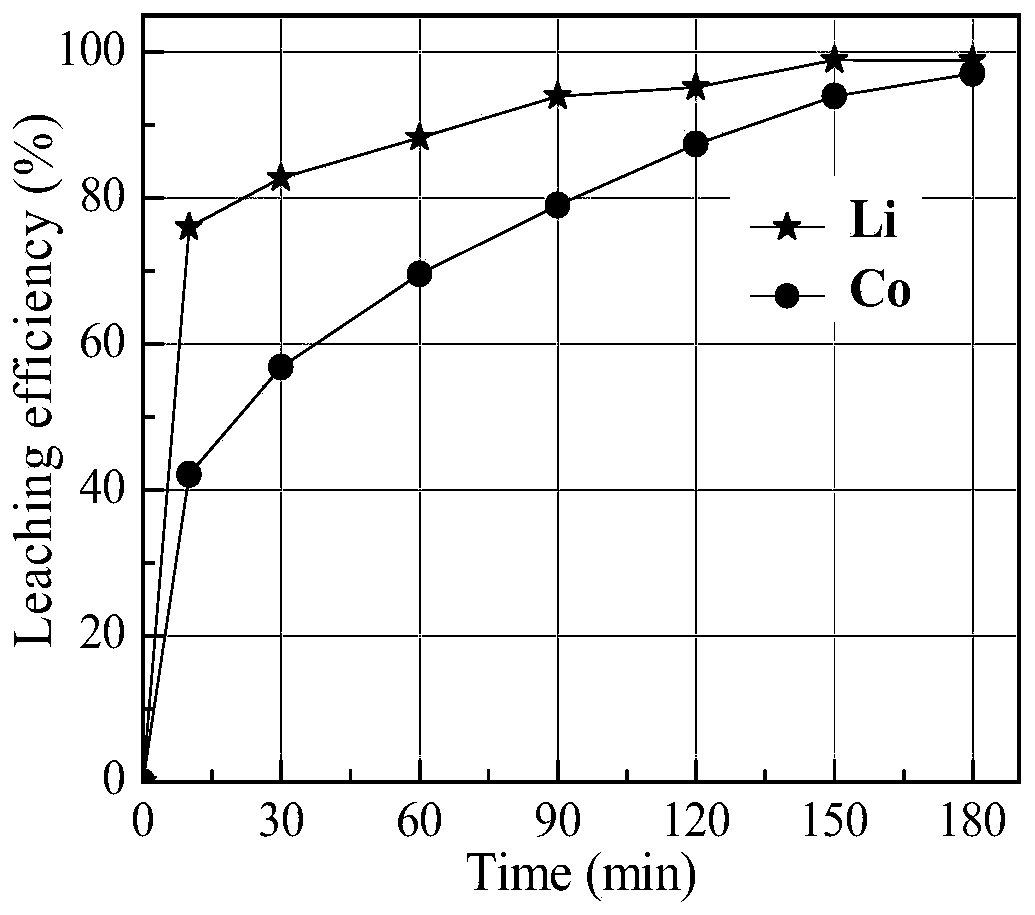

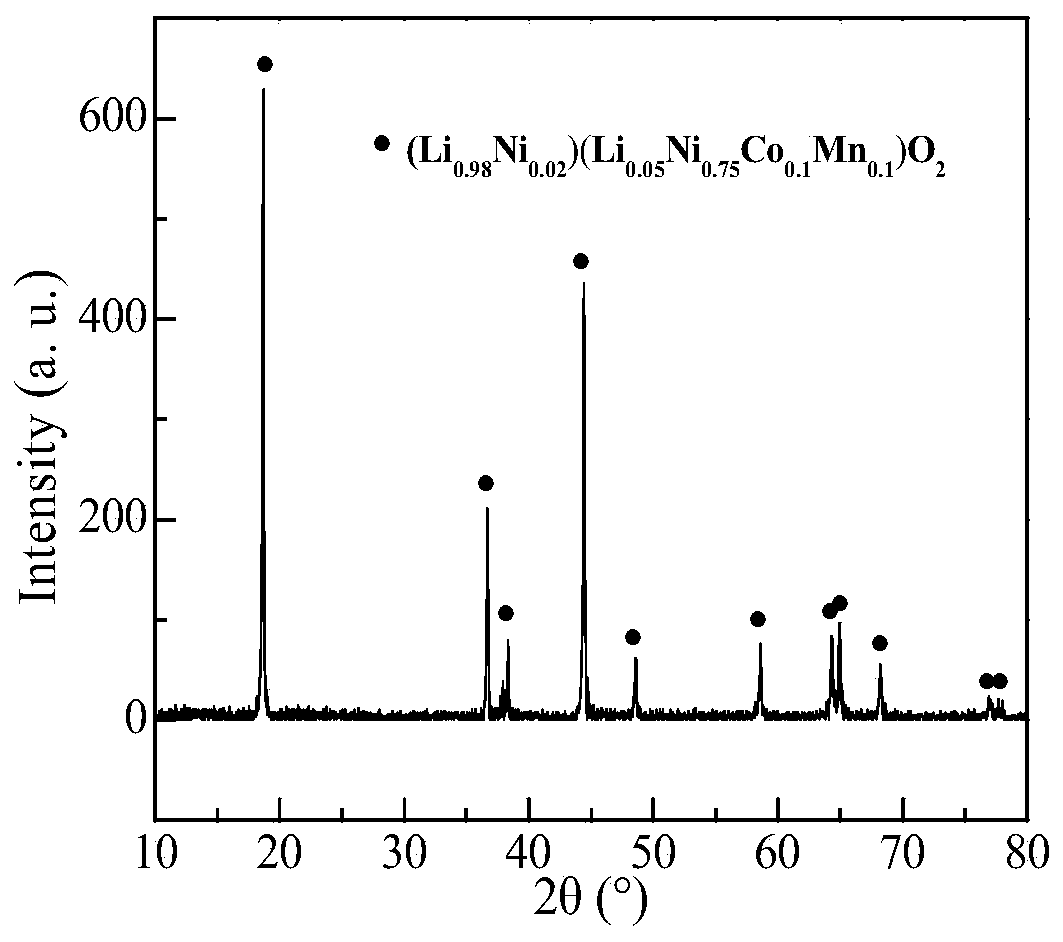

The invention belongs to the field of waste battery resource recycling, and discloses a leaching system and leaching method for valuable metal in a waste lithium battery. According to the leaching method, a sulfamic acid-glucose leaching agent is pre-heated, positive electrode powder is added, and stirring and leaching in a reaction kettle are performed, Co (III) and Mn (IV) are reduced to Co (II)and Mn (II) which are dissolved in a leaching liquid with Li<+> and Ni<2+>, Li, Co, Ni and Mn leaching rate in the waste battery positive electrode powder can reach 95% or above, and recycling or reusing of Li, Co, Ni and Mn can be achieved after further processing the leaching liquid. Compared with a traditional leaching liquid, the leaching system has the advantages of greenness, environmentalfriendliness, safe and controllable leaching process and relatively good industrial application prospect.

Owner:CENT SOUTH UNIV +1

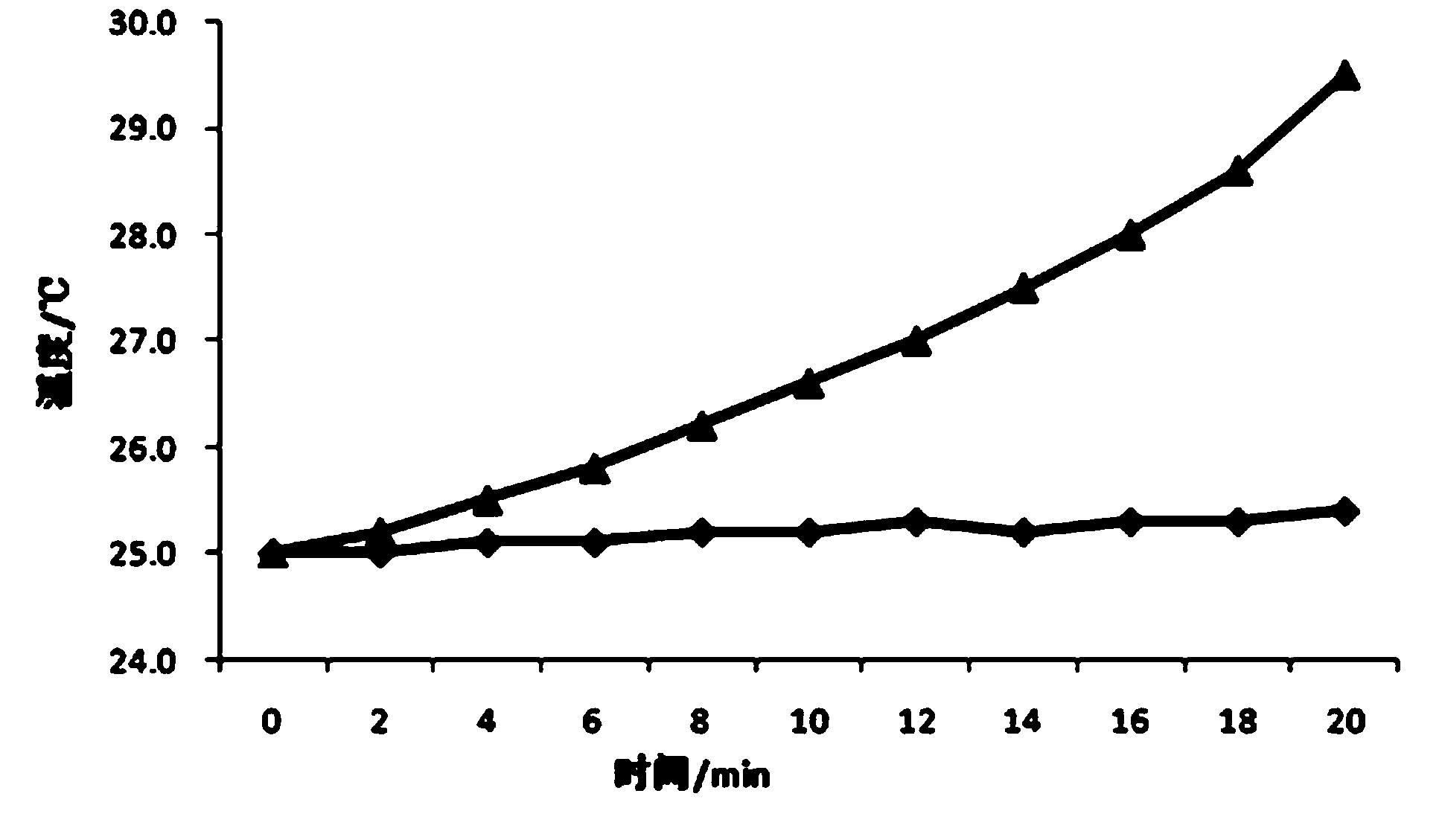

Preparation method of metal resin complex and metal resin complex prepared thereby

ActiveCN103451704AReduce reaction exothermImprove bindingSurface reaction electrolytic coatingAlloy substratePhosphoric acid

The invention provides a preparation method of a metal resin complex and the metal resin complex prepared thereby. The preparation method of the metal resin complex comprises the following steps: S1, anodic oxidation: a metal substrate with a surface comprising an anodic oxidation film layer is obtained by anodic oxidation of a pretreated metal substrate, and the metal substrate is an aluminum alloy substrate or aluminum substrate; S2, treatment with phosphoric acid: the metal substrate containing the anodic oxidation film layer and obtained by the step S1 is immersed in a phosphoric acid solution for treatment to obtain a surface treated metal substrate; and S3, injection: the surface of the surface treated metal substrate is injected with a resin composition, and then the metal resin complex is obtained after molding. In the metal resin complex, the binding force between metal and resin is strong, and the process is simple, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

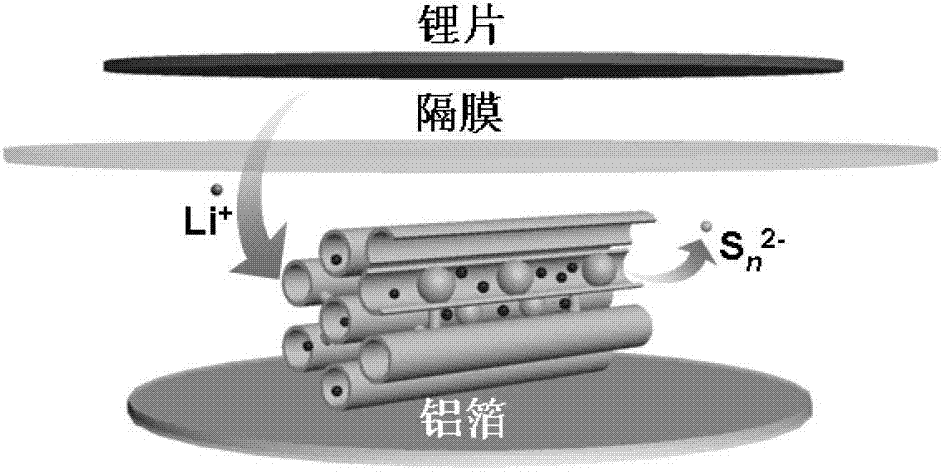

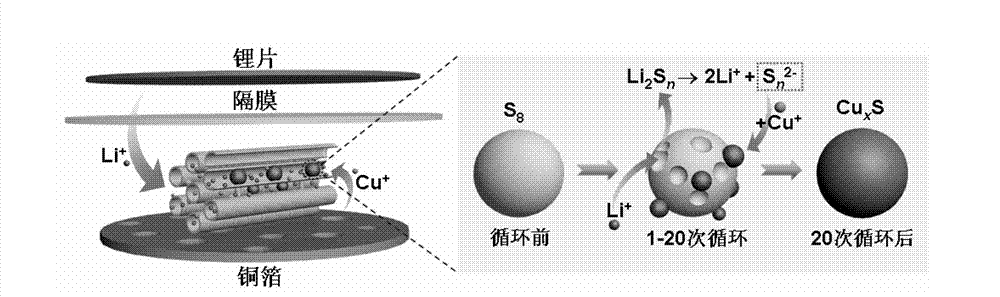

Lithium sulfur battery

InactiveCN103050729AImprove lithium storage performanceSlow corrosionElectrode carriers/collectorsLi-accumulatorsLithium–sulfur batterySulfide

The invention provides a lithium sulfur battery taking a transition metal material as a current collector, which comprises a positive electrode, a negative electrode, an electrolyte, a diaphragm and a battery case, wherein the positive electrode is composed of the transition metal material current collector, a sulfur-based composite applied onto the current collector, a conductive agent and a bonding agent. The transition metal current collector adopted in the battery can be corroded by the electrolyte or oxidized during the charging / discharging process, so as to release transition metal ions, which can rapidly react with an intermediate product Sn2- of the lithium sulfur battery to generate a transition metal sulfide precipitate and further prevent the Sn2- from escaping. Meanwhile, the transition metal sulfide has outstanding electrochemical activity, can improve utilization rate of active sulfur, and further improves reversible capacity. Therefore, due to use of the transition metal current collector, the performance of the lithium sulfur battery is significantly improved.

Owner:DALIAN UNIV OF TECH

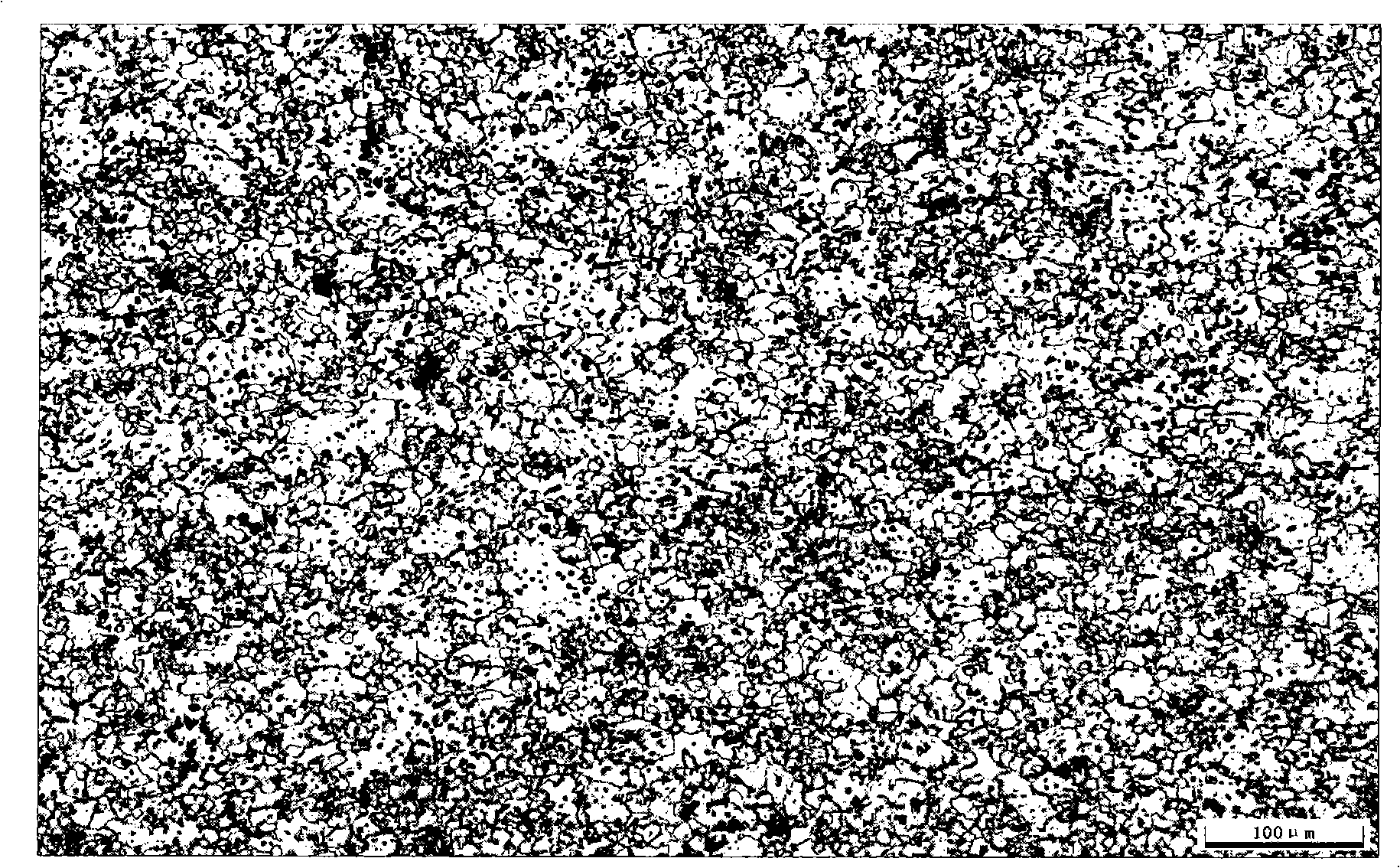

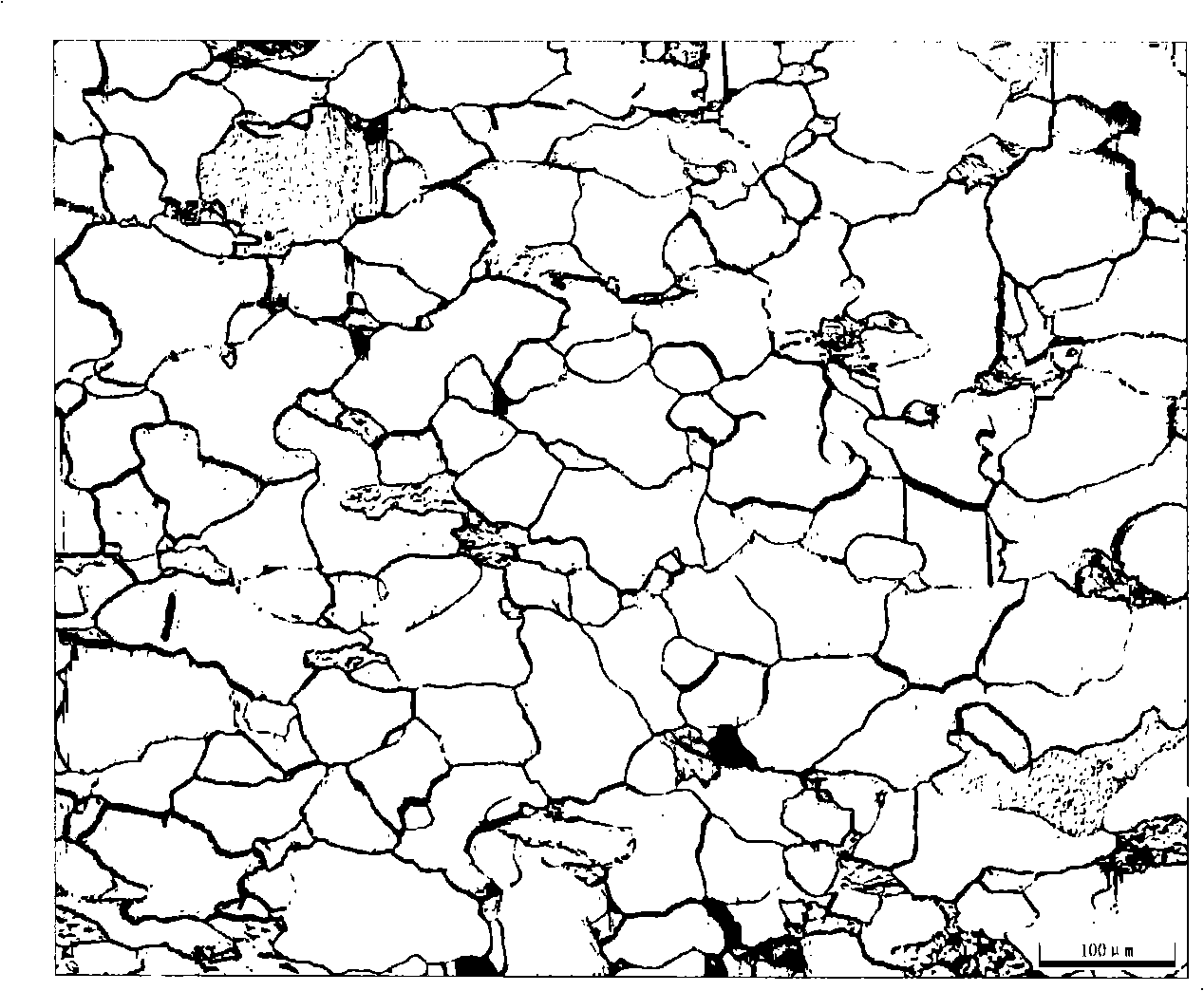

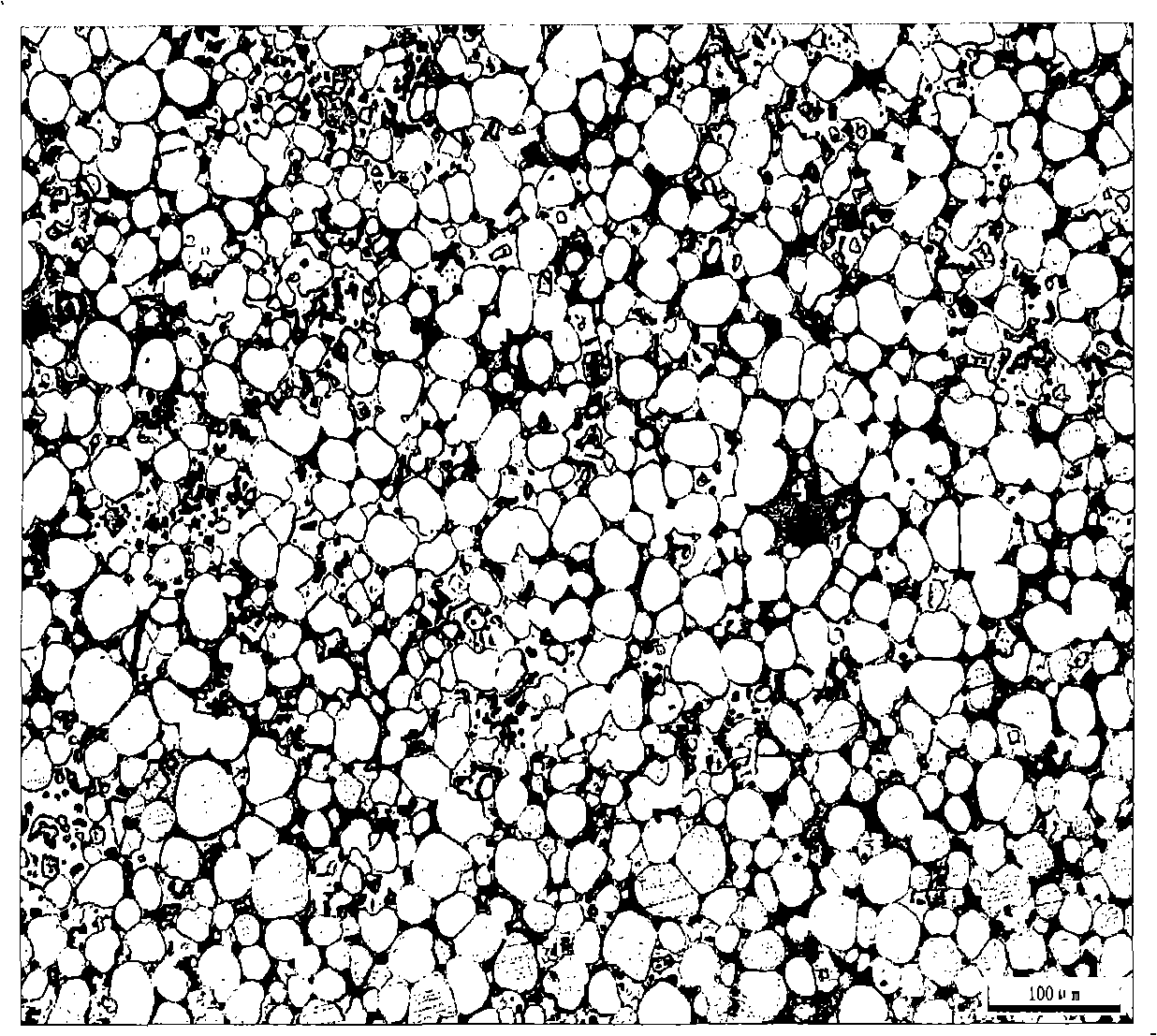

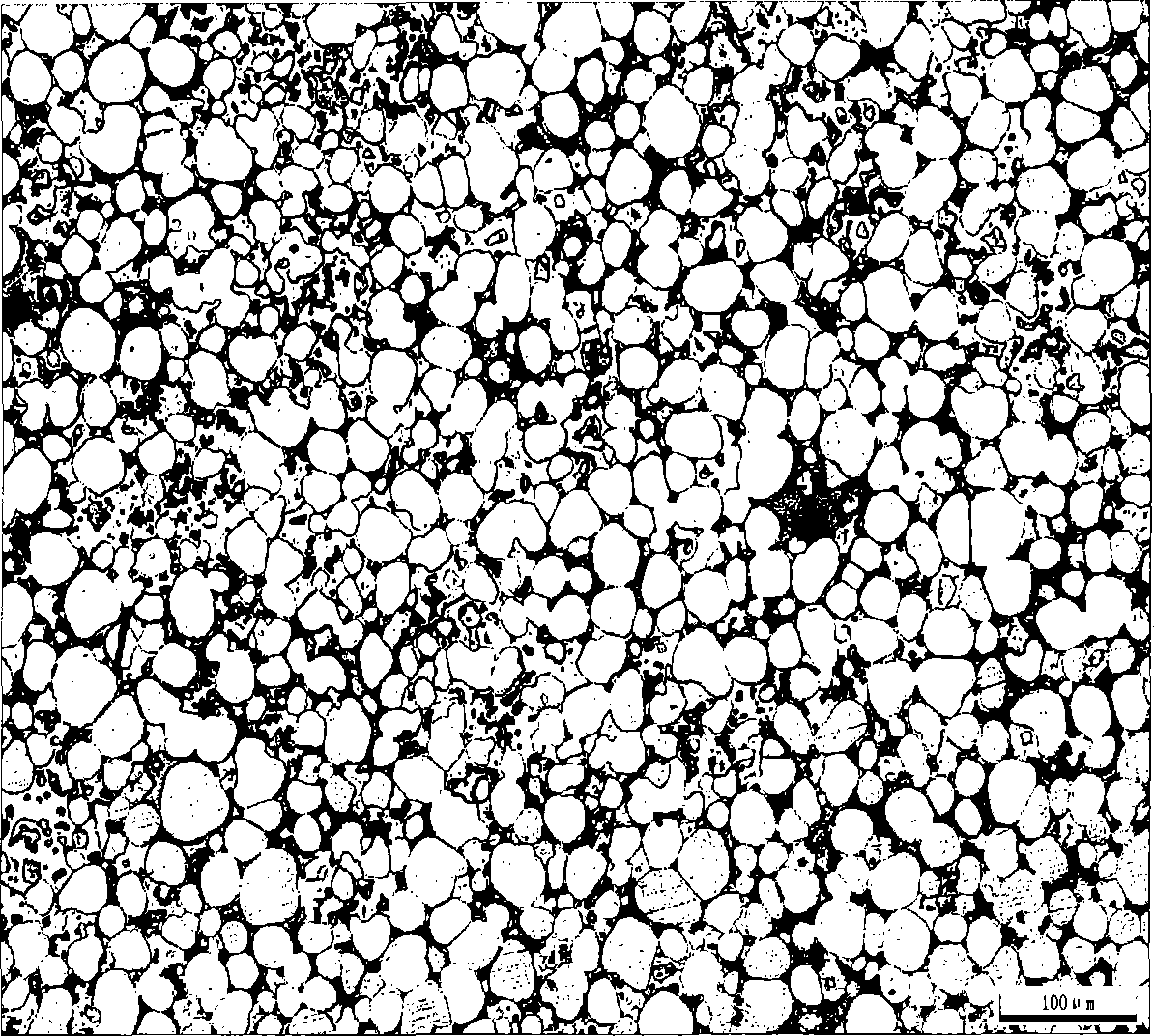

Method for observing tungsten material product microscopic structure

InactiveCN101354326AReflect organizational formEliminate generationPreparing sample for investigationSurface/boundary effectAqueous solutionSurface grinding

The invention discloses a method for observing the metallographic microstructure of tungsten material products, which relates to a metallographic method adopting a chemical etching method for etching and observing the metallographic microstructure of tungsten products. The method of the invention comprises the following steps: surface grinding, lapping and polishing of tungsten material products and is characterized in that: after being treated by surface grinding, lapping and polishing, a mixed solution of HNO3 and HF is utilized to etch the surface of the tungsten material product, and then an aqueous solution of K3Fe(CN)6 and NaOH is adopted to scrub the etched surface of the tungsten material product so that the metallographic microstructure of the tungsten material product can be observed. The method of the invention has low etching speed, is easy to control and eliminates an oxide film generated after tungsten is etched. In addition, the fine metallographic sample of tungsten is produced and the organization form of tungsten is represented precisely.

Owner:西安汉唐分析检测有限公司

Dissecting process for diode device

InactiveCN102646618ASlow corrosionUniform corrosionSemiconductor/solid-state device manufacturingSemiconductor devicesRetention timeCopper

The invention discloses a dissecting process for a diode device. The dissecting process comprises the steps of: 1) continuously heating concentrated sulfuric acid with concentration of 98 percent in a beaker to 95 DEG C; 2) putting the diode device in the concentrated sulfuric acid; 3) putting the diode device in clean water for ultrasonic oscillation cleaning; 4) putting the diode device treated in the step 3 in acetone solution; 5) forming first mixed solution in a beaker by using nitric acid and hydrogen peroxide according to a ratio of 5 to (0.8-1.2) and immersing the diode device in the first mixed solution; 6) forming second mixed solution in a beaker by using nitric acid and water according to a ratio of 5 to (1.8-2.2) and putting the diode device which is decoppered in the step 5) in the second mixed solution in a boiling state and keeping retention time to be 5-10 minutes; and 7) washing the diode device with water, immersing the diode device in acetone solution for oscillation dewatering and keeping washing time to be 20-40 seconds to obtain a diode chip. By adopting the dissecting process, when an epoxy layer is removed, the internal structure of the device is not influenced at all and the reliability of data analysis is greatly improved.

Owner:SUZHOU GOODARK ELECTRONICS CO LTD

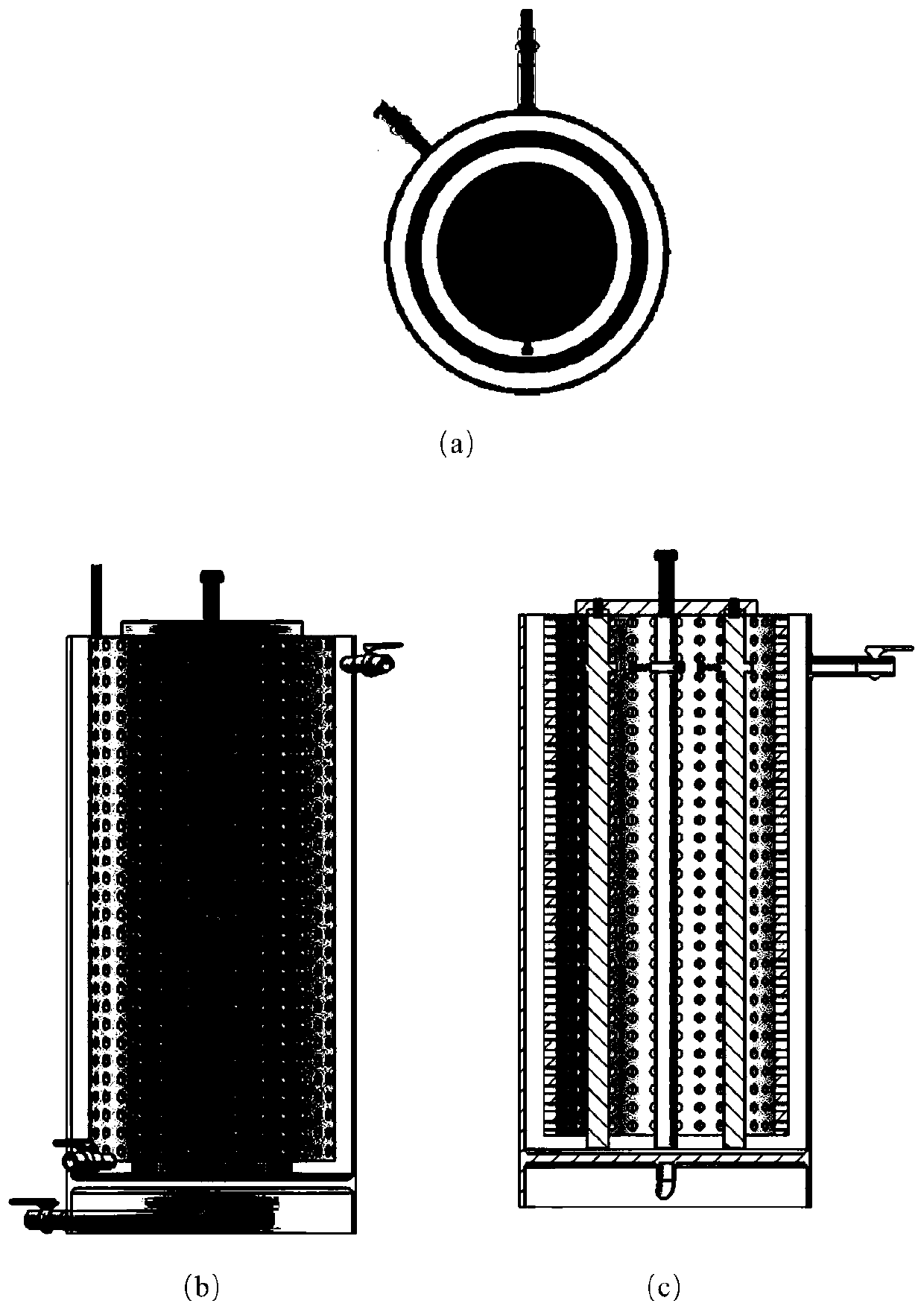

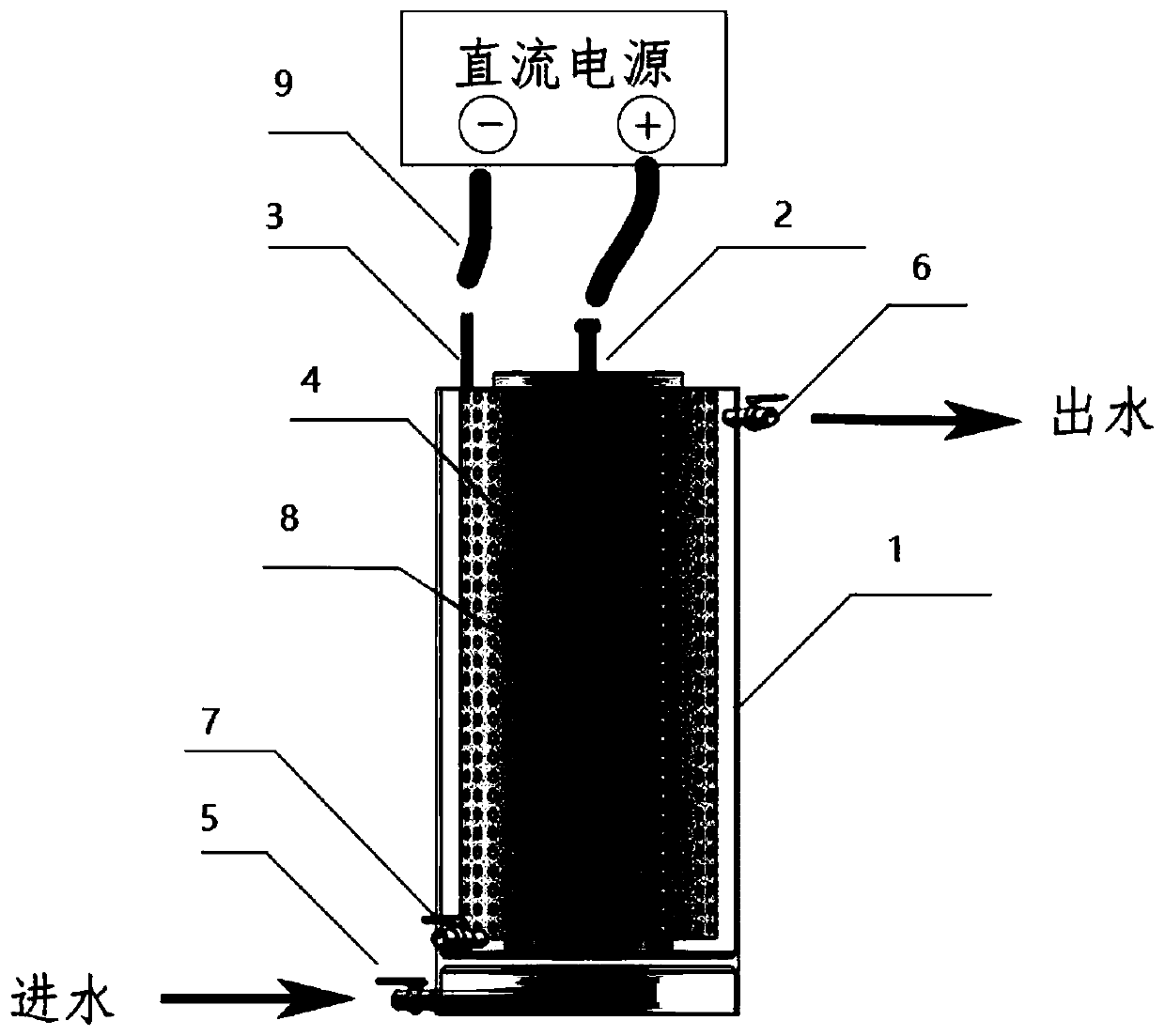

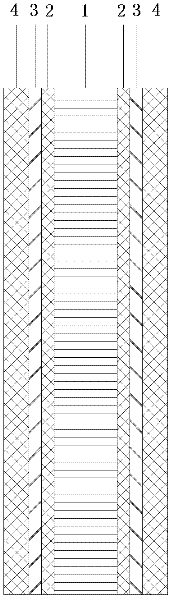

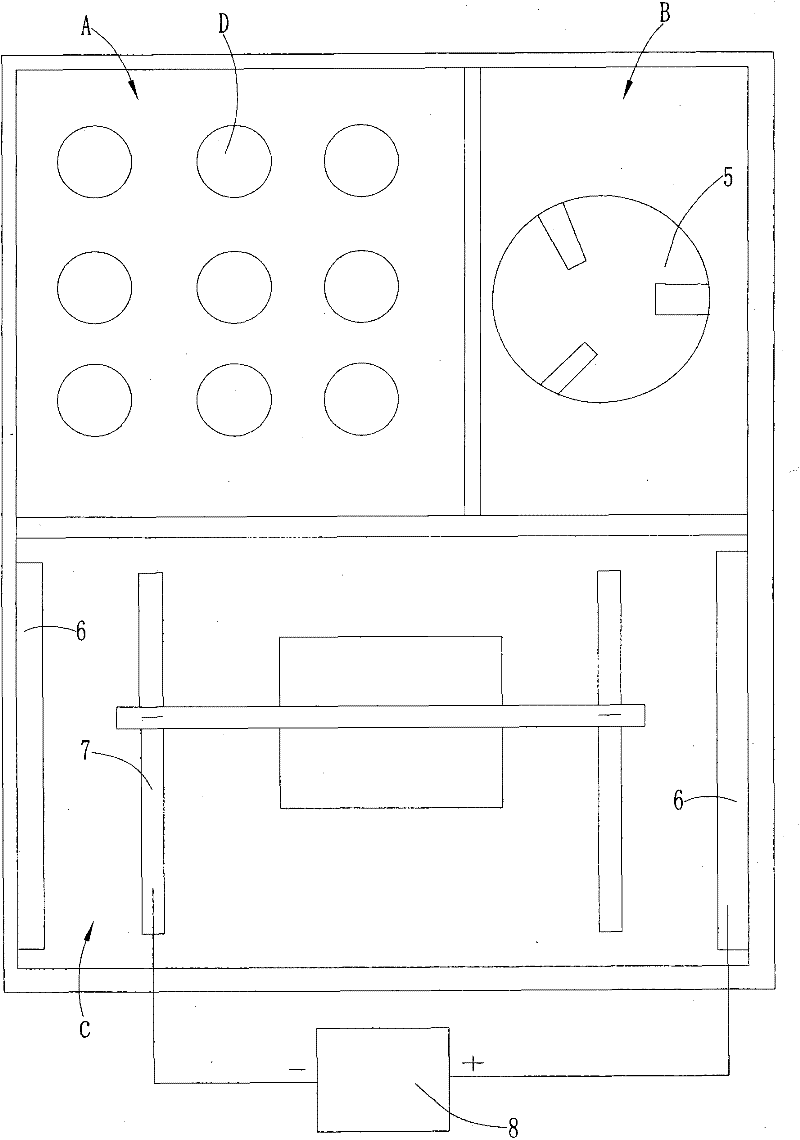

Bio-membrane reactor for treating low-carbon-nitrogen-ratio wastewater and refractory organic matters

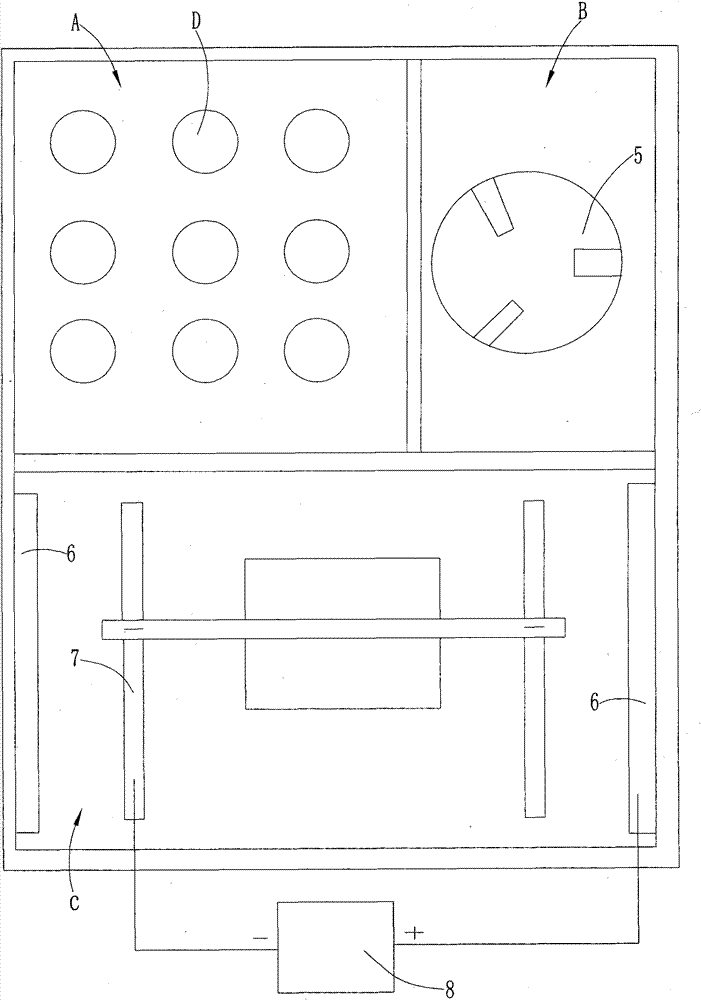

InactiveCN111252887AImprove operational efficiencyIncrease contact timeTreatment by combined electrochemical biological processesWater treatment compoundsElectrolysisElectron donor

The invention discloses a bio-membrane reactor for treating low-carbon-nitrogen-ratio wastewater and refractory organic matters. The reactor comprises a shell, an anode, a cathode, sponge iron, an activated carbon filling layer, a direct-current power supply, a water inlet pump, a water inlet pipe and a drain pipe, wherein a water inlet is formed in the bottom of the shell; a water outlet is formed in the upper part of the shell; wherein the cathode is of a cylindrical porous structure, the anode is of a disc four-cylinder structure, the anode is sleeved in the middle area of the cathode, sponge iron and an activated carbon filling layer are filled between the anode and the cathode, the anode is connected with the anode of the direct-current power supply, and the cathode is connected withthe cathode. In the same reactor, an electrode is used for electrolyzing wastewater to generate hydrogen, an environment suitable for microbial growth is created, an electron donor and an intermediatewith strong oxidizing property are provided for denitrification and ibuprofen degradation respectively, the purpose of removing nitric acid nitrogen and ibuprofen in a low carbon-nitrogen ratio is achieved, and the bio-membrane reactor has the advantages of low energy consumption, high efficiency, simple structure and simplicity in operation.

Owner:BEIJING UNIV OF CHEM TECH

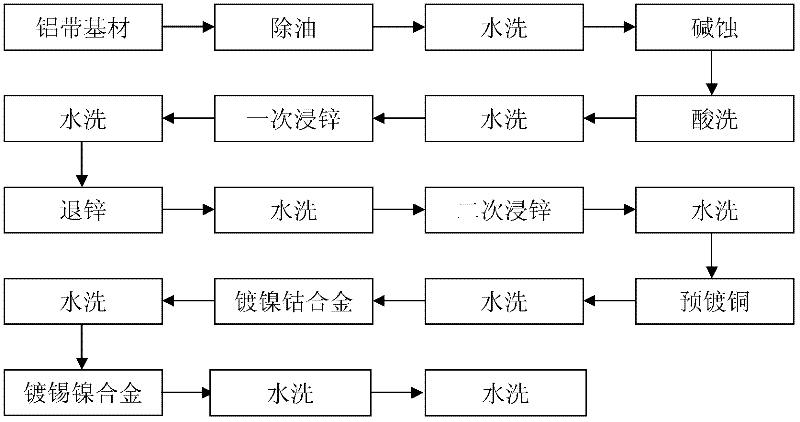

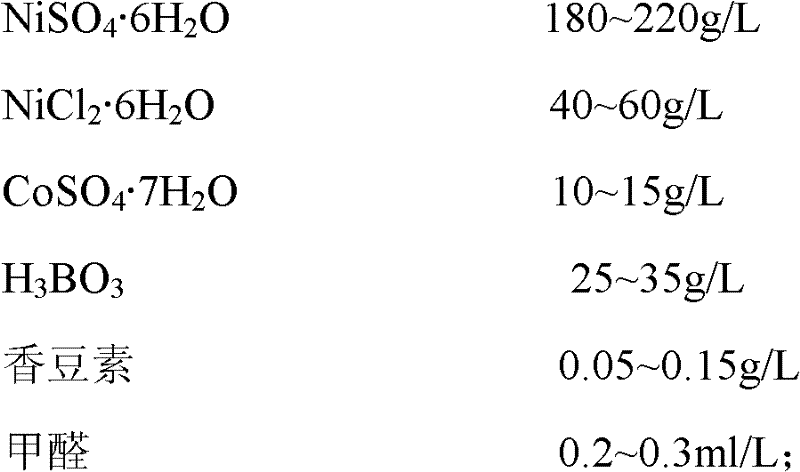

Aluminium strip with tin soldering performance and high corrosion resistance and preparation technology thereof

ActiveCN102212855AImprove corrosion resistanceImprove acid and alkali corrosion resistanceLiquid/solution decomposition chemical coatingCopper coatingNickel alloy

The invention discloses an aluminium strip with tin soldering performance and high corrosion resistance and a preparation technology thereof. The aluminium strip can be widely applied to various fields of electrons, energy, precise instruments, automobiles and the like, and the problem that the aluminium strip is difficult to weld is solved. According to the aluminium strip and the preparation technology thereof, aluminium and aluminium alloy strips (aluminium strips for short) serve as a substrate; two surfaces of the substrate are successively electroplated with a copper coating, a nickel and cobalt alloy coating and a tin and nickel alloy coating; and multiple electroplated membranes and the substrate have the advantages of good bonding force, strong anticorrosion performance and better tin soldering performance. The aluminium strip prepared by the preparation technology can be produced by a continuous electroplating method so as to satisfy the requirement on aluminium strip surface treatment.

Owner:HUNAN YONGSHENG NEW MATERIALS

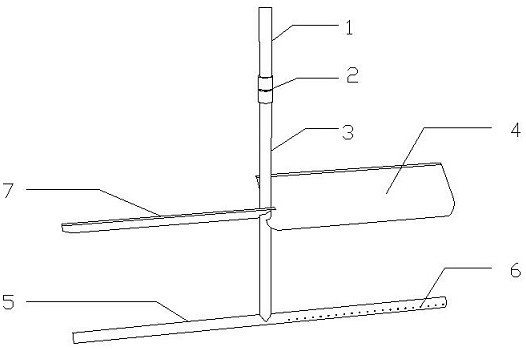

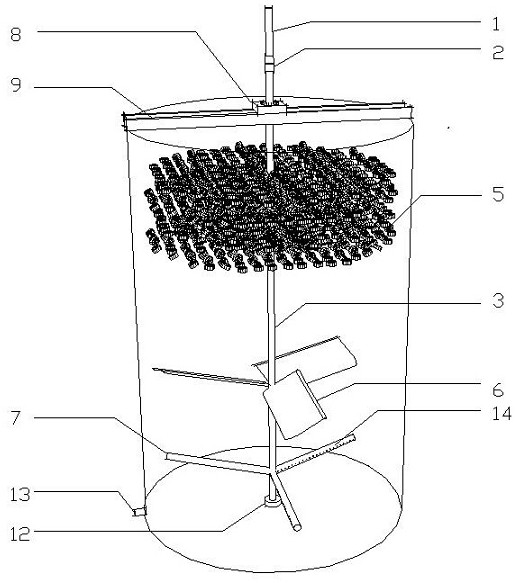

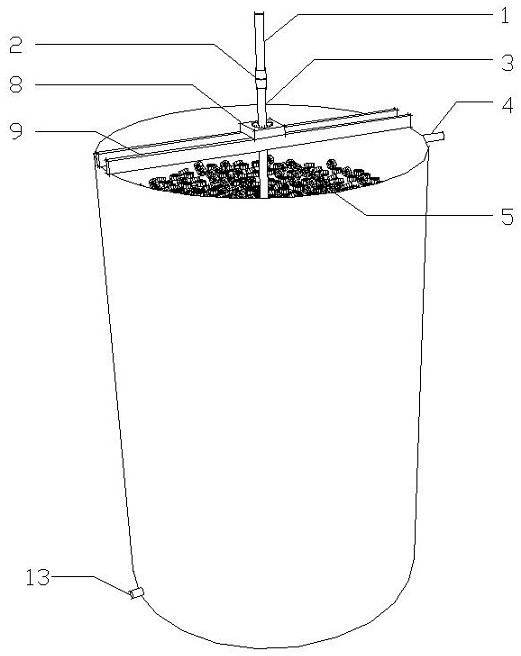

Self-driven rotary aeration device

PendingCN112678946AContinuous rotary aerationPromote mixed contactSustainable biological treatmentBiological water/sewage treatmentMicroorganismThermodynamics

The invention provides a self-driven rotary aeration device which comprises a fixed air vertical pipe and a movable air vertical pipe, the fixed air vertical pipe and the movable air vertical pipe are connected through a rotary joint, inclined blades are arranged on the movable air vertical pipe, a rotary transverse pipe is arranged at the bottom end of the movable air vertical pipe, and air outlet holes are formed in the rotary transverse pipe. Compared with fixed aeration, rotary aeration has the advantages that the proportion of a bubble activity space in an aeration reactor in the whole space can be increased, uniform air distribution is promoted, uniform fluidization of the filler is promoted, the phenomena of filler accumulation or ball death and the like are prevented, and sludge sedimentation can also be prevented. Rotation of the rotating blades can also promote mixed contact of water, gas and microorganisms in the reactor, and mass transfer is enhanced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

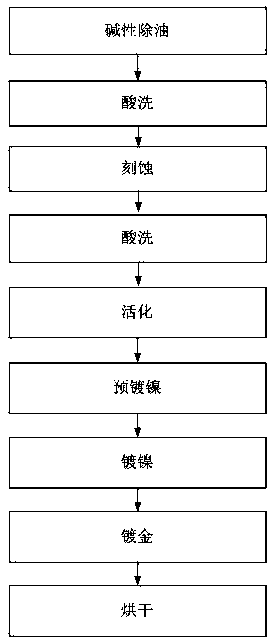

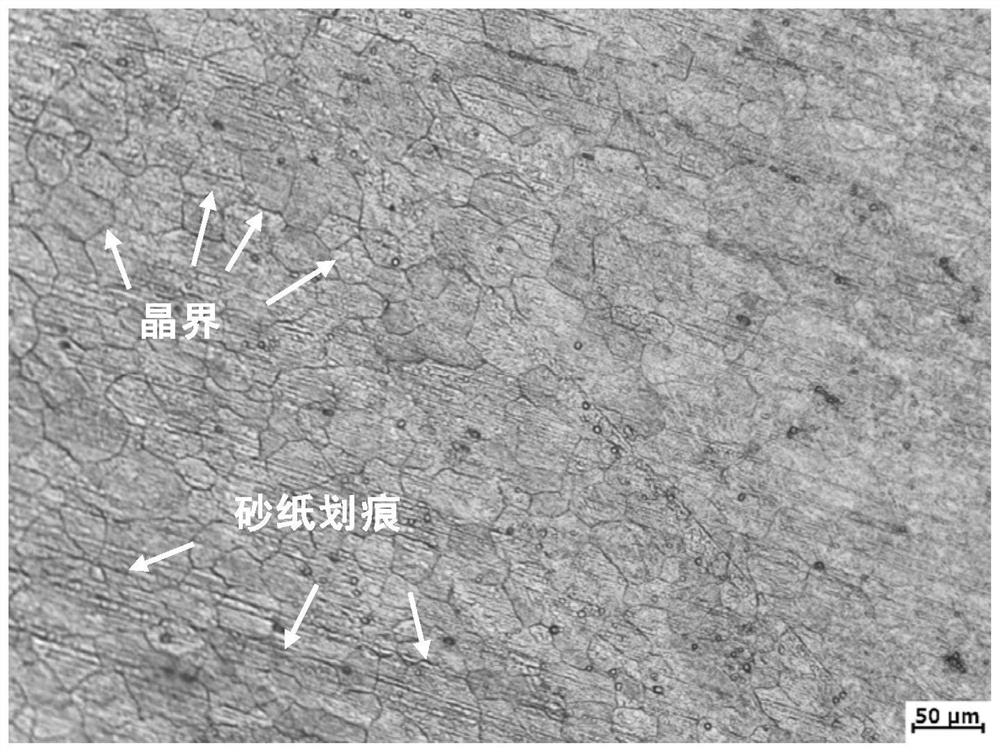

Method for improving welding performance of copper surface heat sink for packaging shell after gold plating

The invention discloses a method for improving the welding performance of a copper surface heat sink for a packaging shell after gold plating. The method comprises the following steps of putting the shell into an alkaline oil removal solution to be cleaned; putting the shell into a pickling solution for cleaning; putting the shell into an etching solution for treatment; putting the shell into a pickling solution for cleaning; putting the shell into an activation solution for pre-plating activation; electroplating a layer of thin nickel on the surface of the shell; electroplating a layer of thick nickel on the surface of the shell; electroplating a layer of thick gold on the surface of the shell; and carrying out high-temperature drying treatment on the washed shell by using a high-temperature blast drying box. According to the invention, etching before plating is carried out on the copper surface heat sink for the packaging shell, etching liquid is corroded along a grain boundary, so that a lattice pattern shape is formed on the copper surface, and after nickel plating and gold plating are subsequently carried out on the basis, the welding performance and the welding yield of the surface of the copper surface heat sink are greatly improved; the etching solution corrodes along the grain boundary, other areas of the copper surface and other materials of the shell are not damaged,and the etching time range is large.

Owner:CETC GUOJI SOUTHERN GRP CO LTD

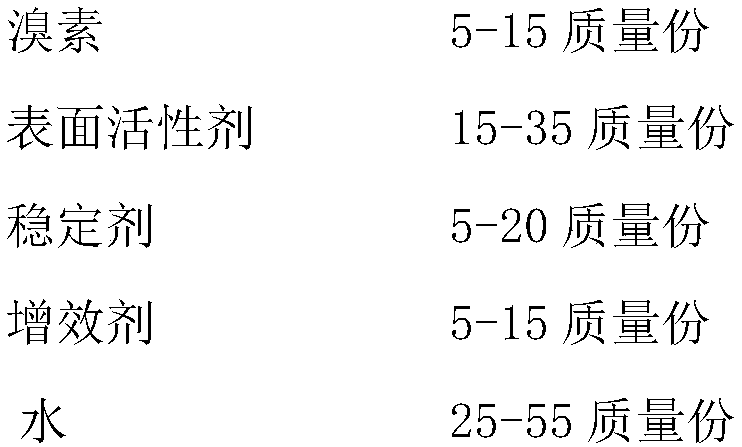

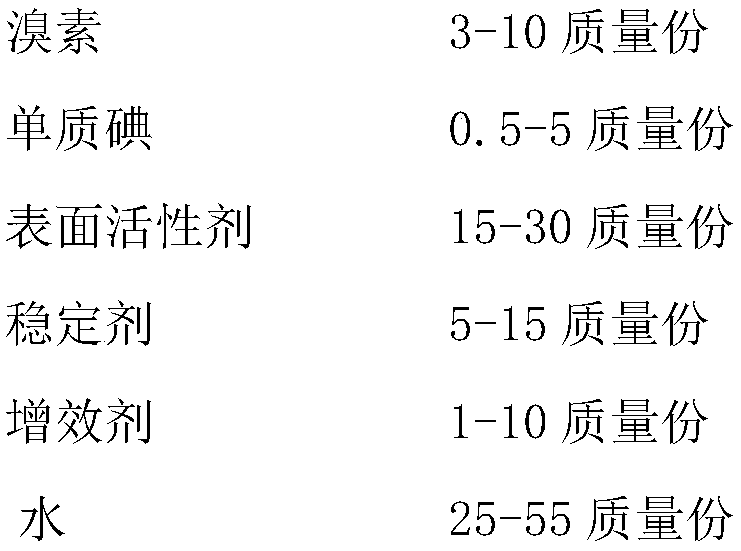

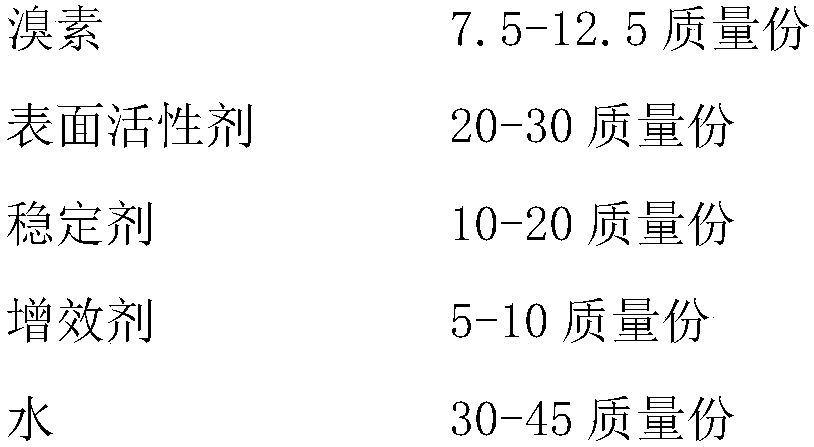

Efficient sterilization disinfectant and preparation method thereof

ActiveCN108013072ASafety irritationWide range of adaptationBiocideSpecific water treatment objectivesBromineChemistry

The invention discloses an efficient sterilization disinfectant and a preparation method thereof. With the aid of the efficient bactericidal performance of bromine and elemental iodine, an appropriateamount of a stabilizer, a surfactant and a synergist are added for preparation of the efficient sterilization disinfectant with the aid of coordination of a complexation method and a micellar solubilization method. The efficient sterilization disinfectant comprises the following main raw materials: the bromine, the surfactant, the stabilizer, the synergist and deionized water; or the bromine, theelemental iodine, the surfactant, the stabilizer, the synergist and the deionized water. The high-efficiency, broad-spectrum and safe compound disinfectant can quickly and thoroughly sterilize, has good stability, is strong in environmental protection property, has no stimulation, has high safety, and is suitable for long-term storage.

Owner:定州市荣鼎水环境生化技术有限公司

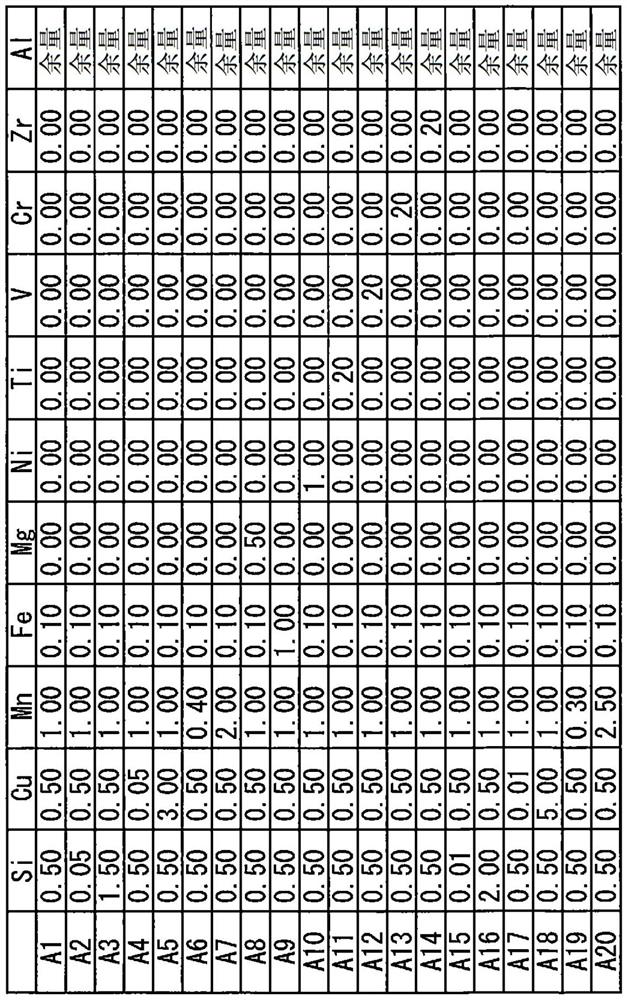

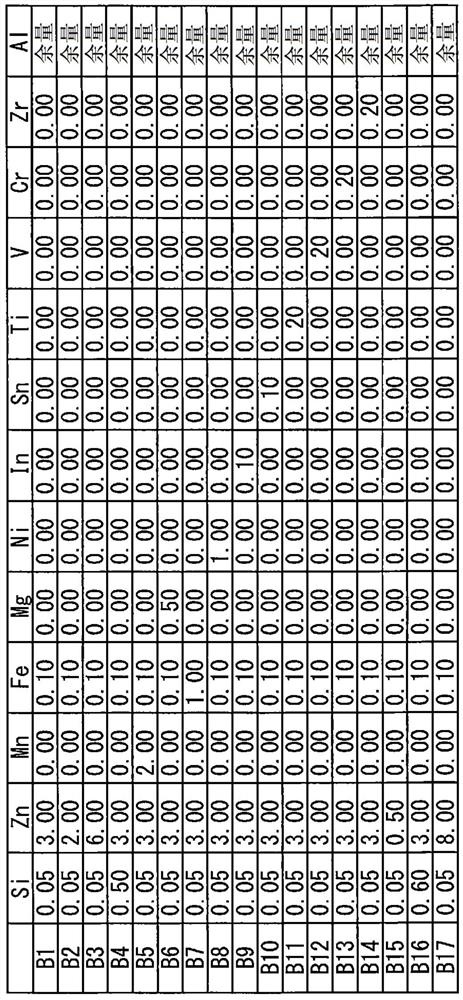

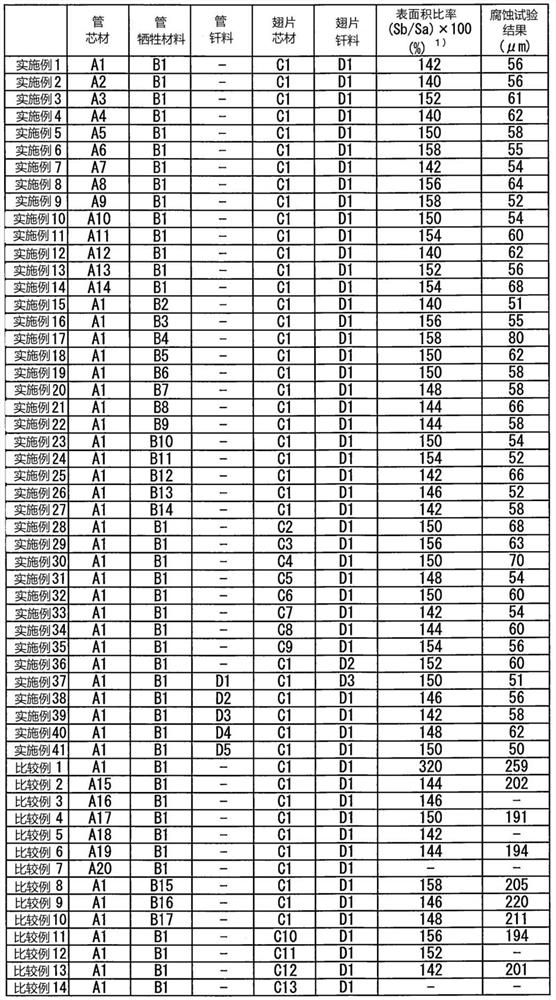

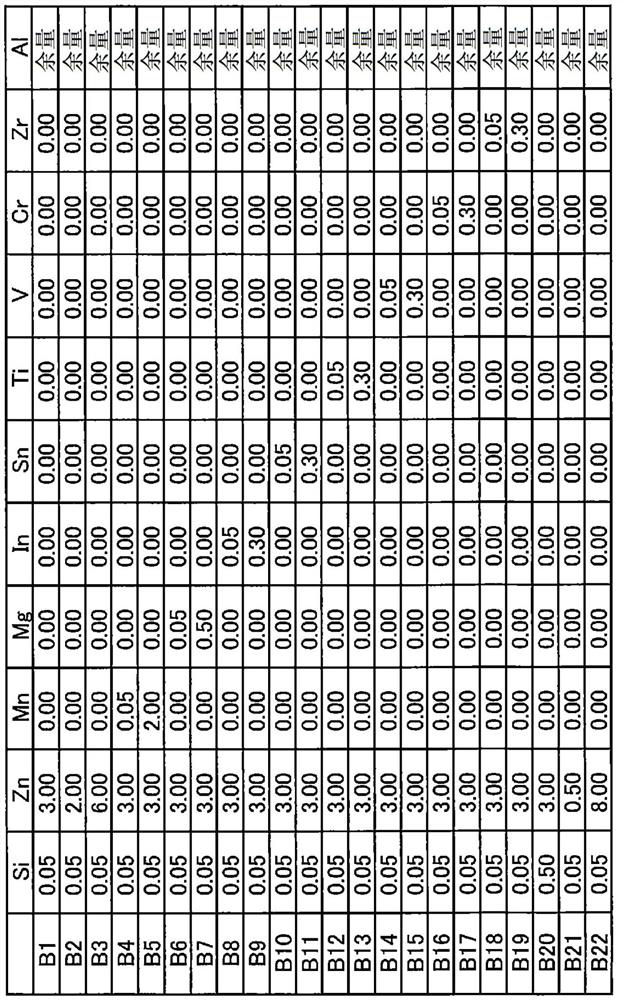

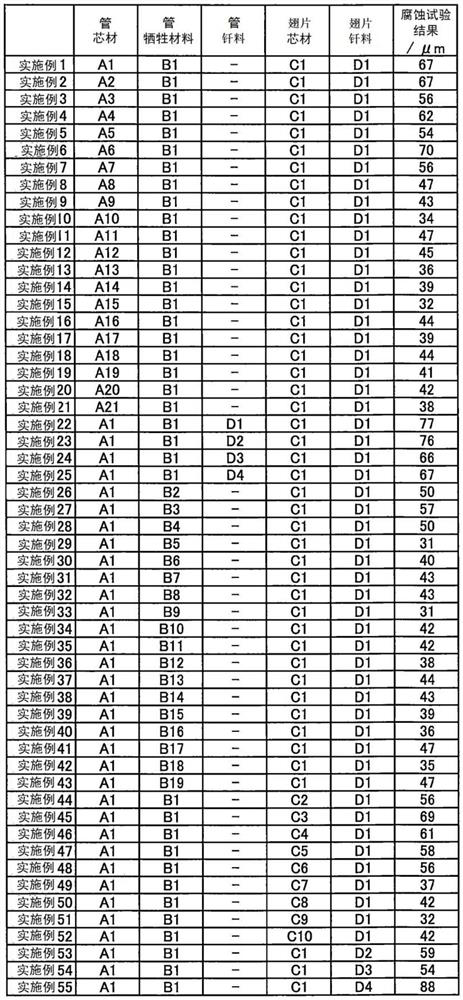

Aluminum alloy heat exchanger for exhaust gas recirculation system

InactiveCN111936646ASlow corrosionSolution to short lifeExhaust gas recirculationIndirect heat exchangersExhaust gas recirculationMaterials science

Provided is an aluminum alloy heat exchanger for exhaust gas recirculation system obtained by brazing a fin material to a tube material. The fin material comprises: a core material containing 0.05-1.50% by mass Si, and 0.40-2.00% by mass Mn; and a brazing material containing 3.00-13.00% by mass Si and clad on both sides of the core material. The tube material comprises: a core material containing0.05-1.50% by mass Si, 0.05-3.00% by mass Cu, and 0.40-2.00% by mass Mn; and a sacrificial anti-corrosion material containing 2.00-6.00% by mass Zn and clad on the inner surface of the core material.The ratio of the surface area Sb (mm<2>) of the fin material to the surface area Sa (mm<2>) of the sacrificial anti-corrosion material is less than 200%. According to this invention it is possible toprovide an aluminum alloy heat exchanger for exhaust gas recirculation system which has a slow corrosion rate and long service life in ammonium environments in which ammonium is contained in the condensate water of exhaust gas.

Owner:FURUKAWA SKY ALUMINUM CORP +1

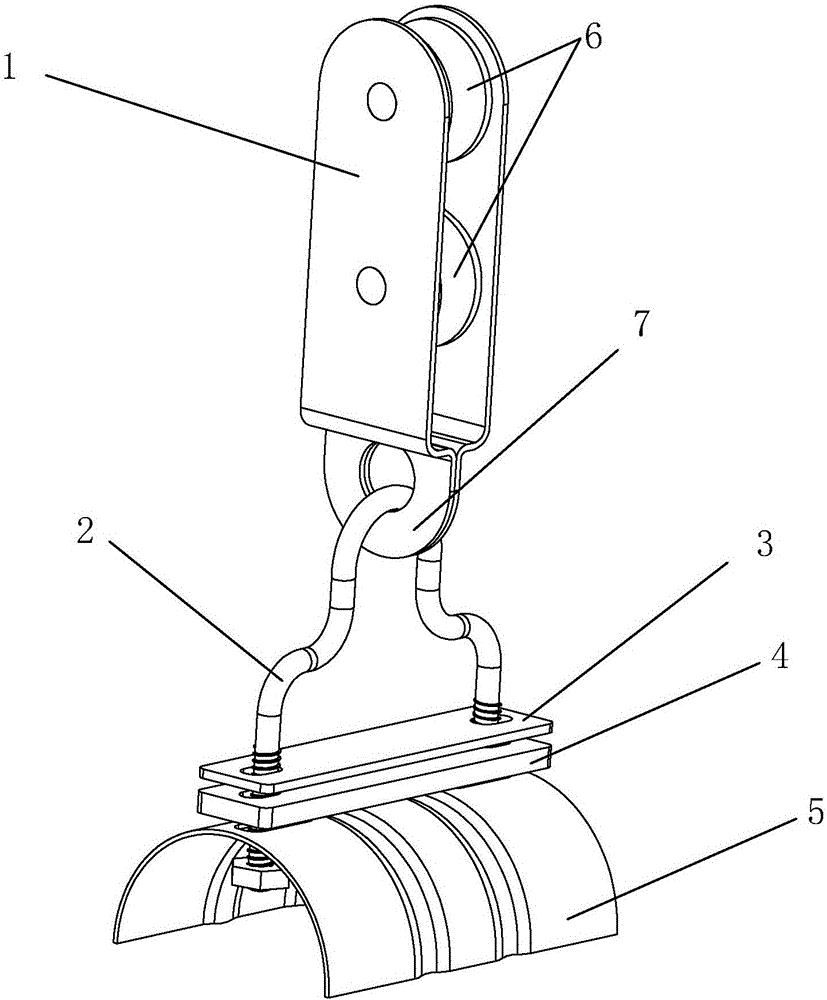

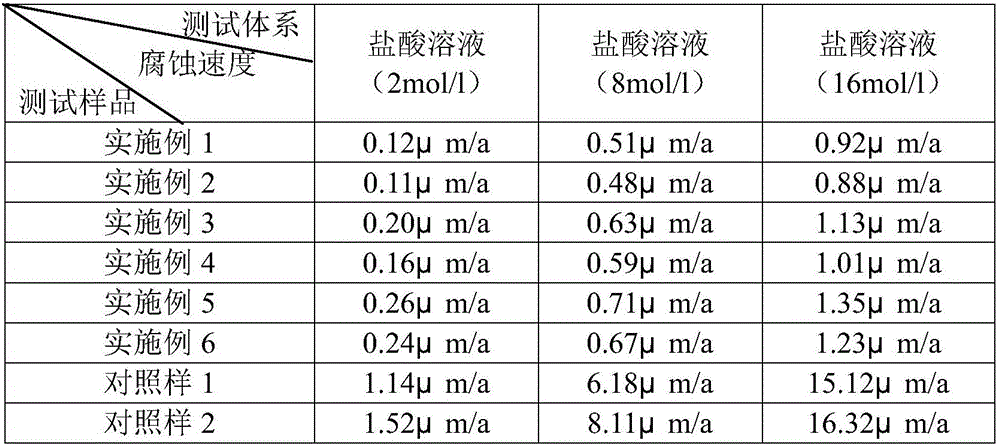

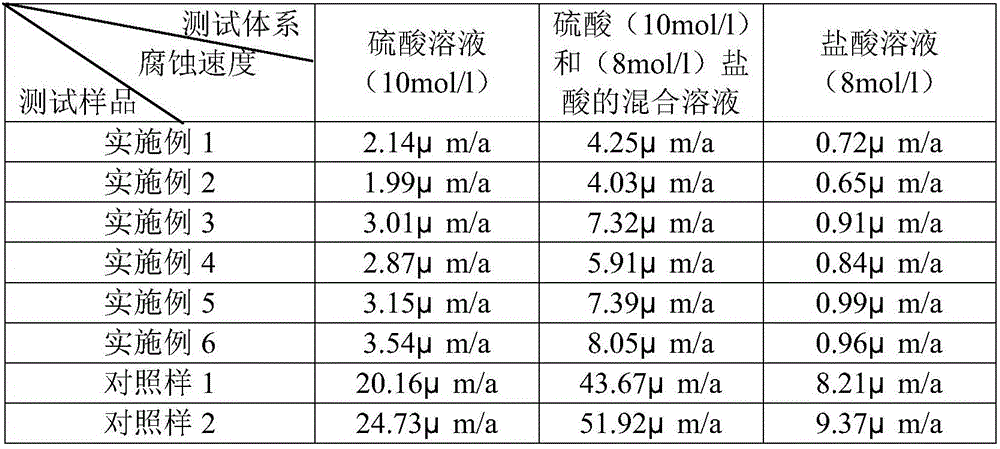

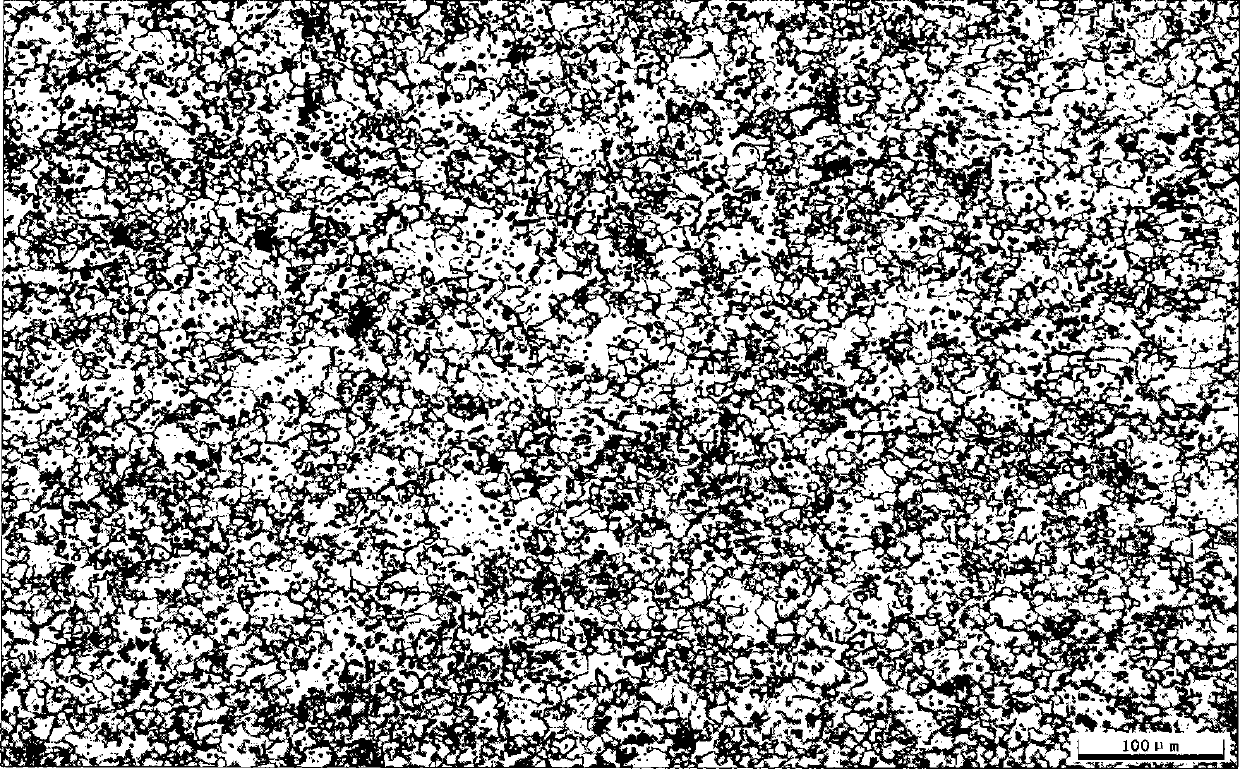

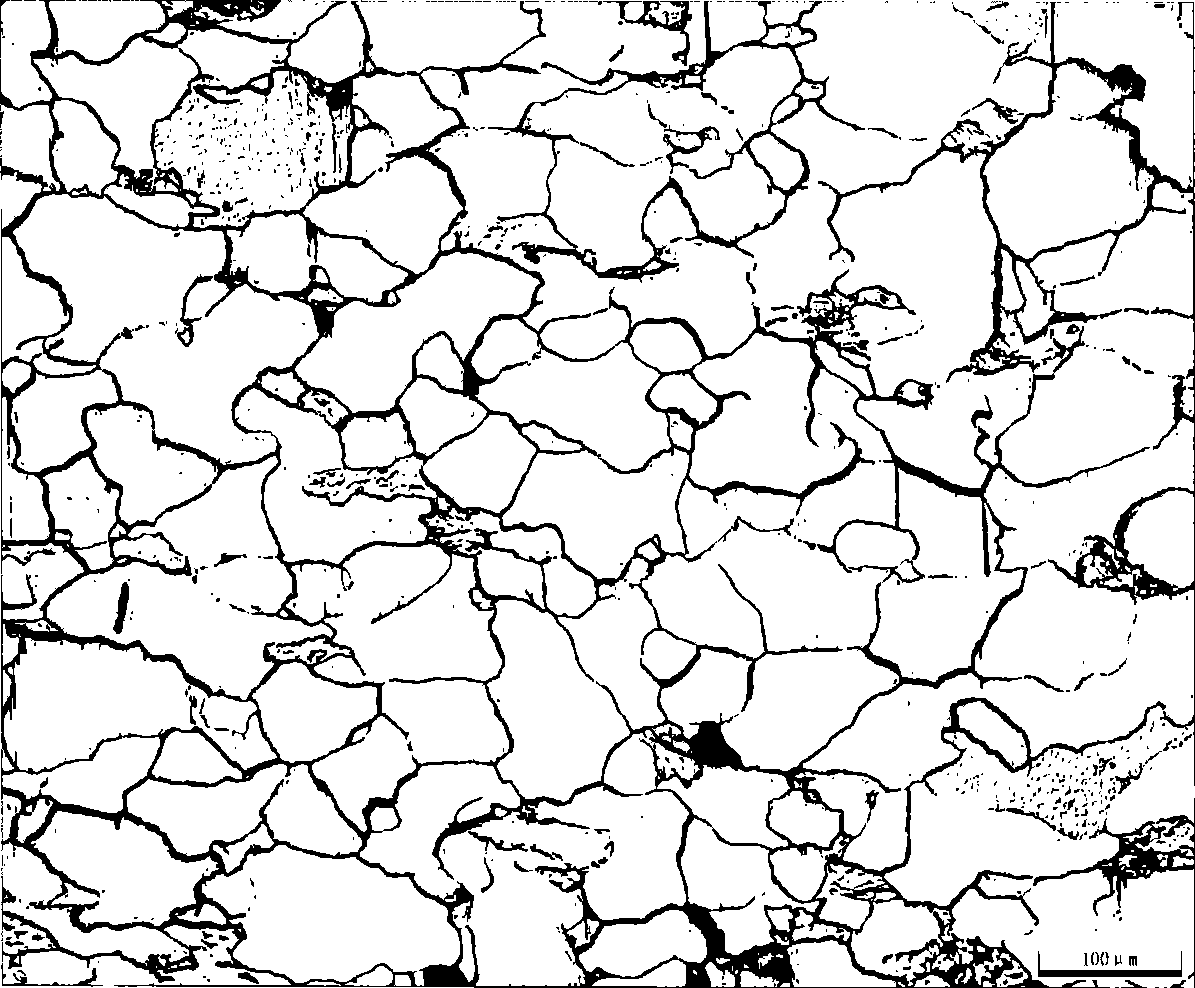

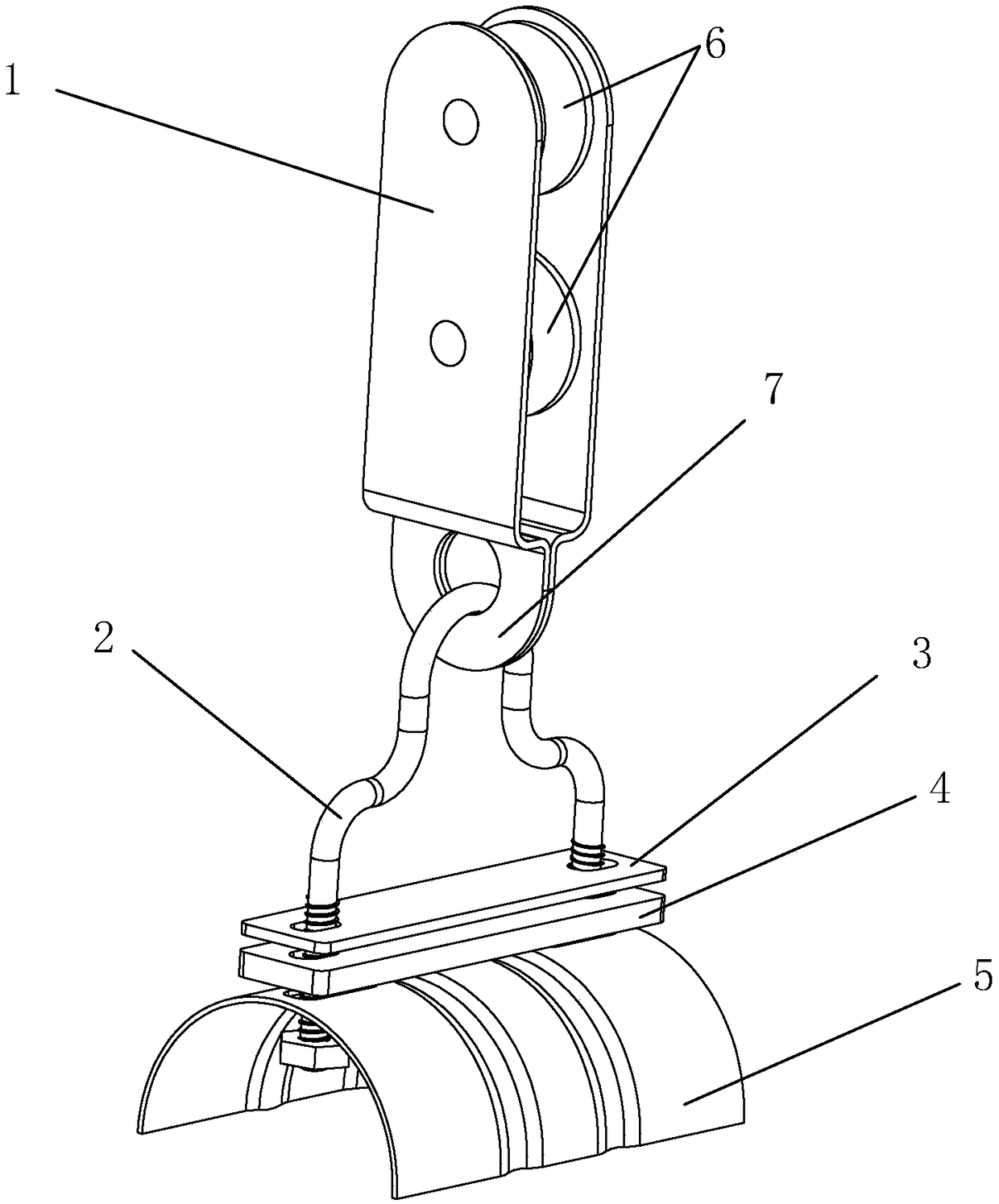

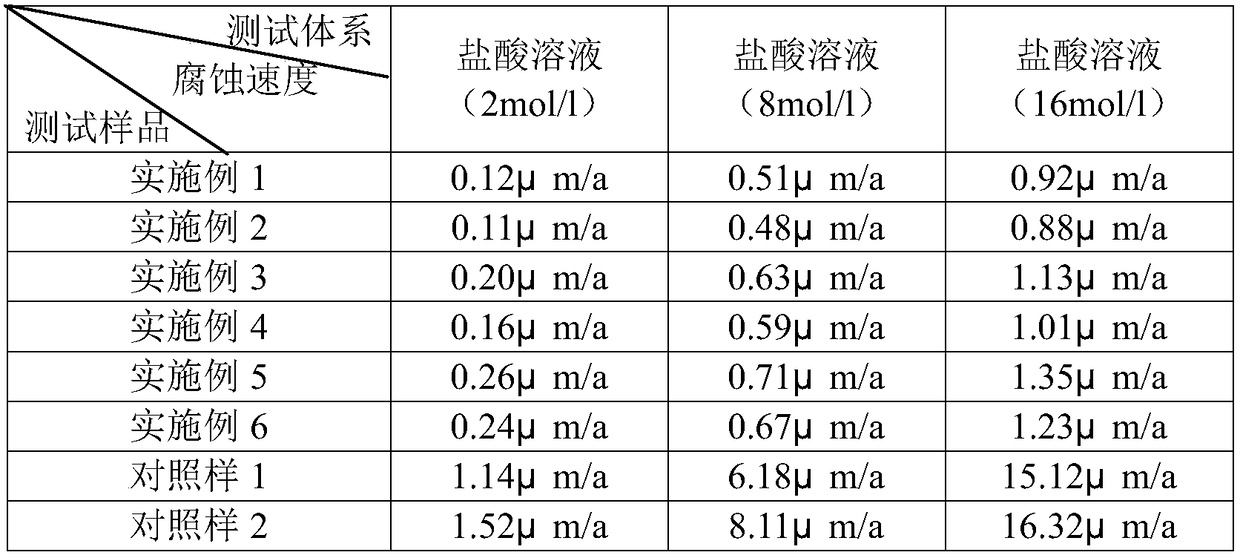

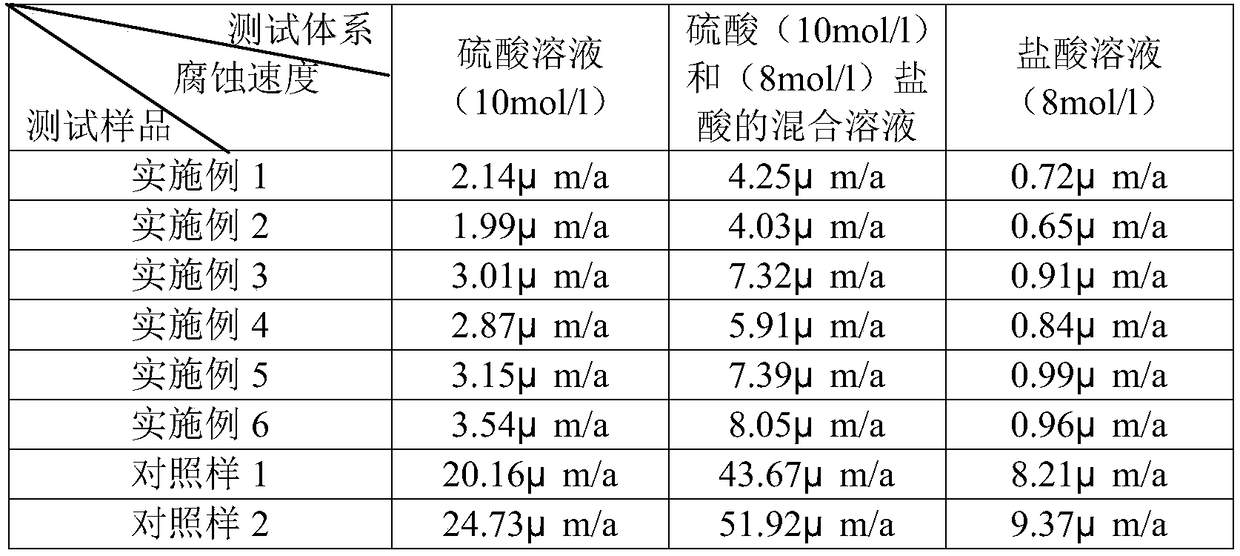

Formula of special stainless steel for crane cable coaster and preparation method thereof

Owner:杭州振华钣金有限公司

Method for observing tungsten material product microscopic structure

InactiveCN101354326BReflect organizational formEliminate generationPreparing sample for investigationSurface/boundary effectSurface grindingTungsten

The invention discloses a method for observing the metallographic microstructure of tungsten material products, which relates to a metallographic method adopting a chemical etching method for etching and observing the metallographic microstructure of tungsten products. The method of the invention comprises the following steps: surface grinding, lapping and polishing of tungsten material products and is characterized in that: after being treated by surface grinding, lapping and polishing, a mixed solution of HNO3 and HF is utilized to etch the surface of the tungsten material product, and then an aqueous solution of K3Fe(CN)6 and NaOH is adopted to scrub the etched surface of the tungsten material product so that the metallographic microstructure of the tungsten material product can be observed. The method of the invention has low etching speed, is easy to control and eliminates an oxide film generated after tungsten is etched. In addition, the fine metallographic sample of tungsten is produced and the organization form of tungsten is represented precisely.

Owner:西安汉唐分析检测有限公司

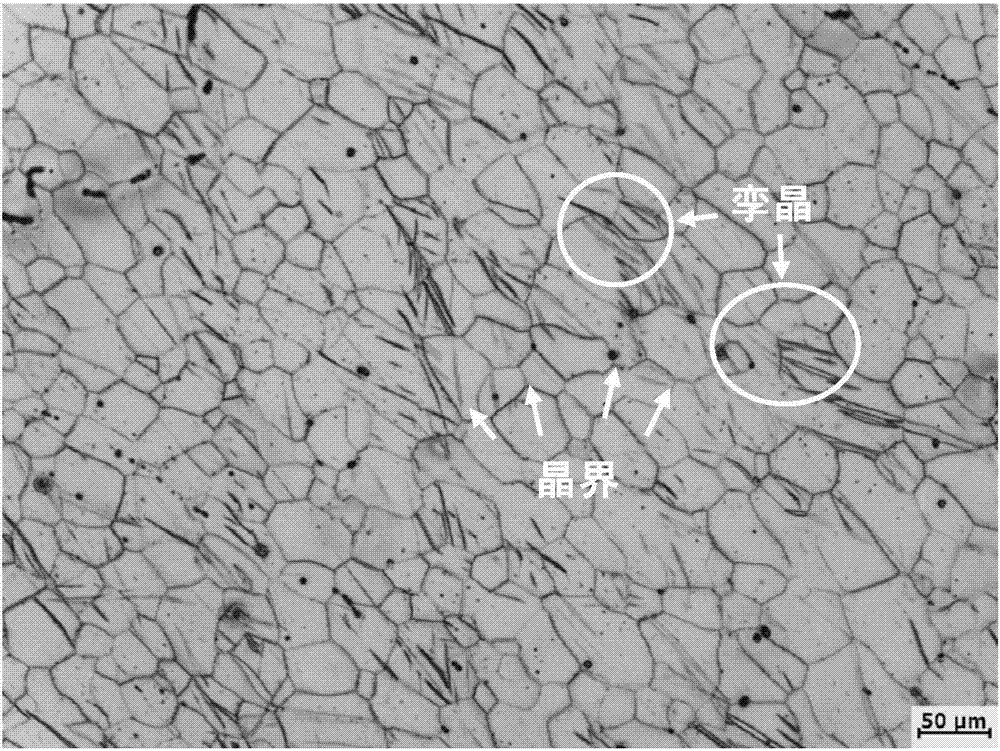

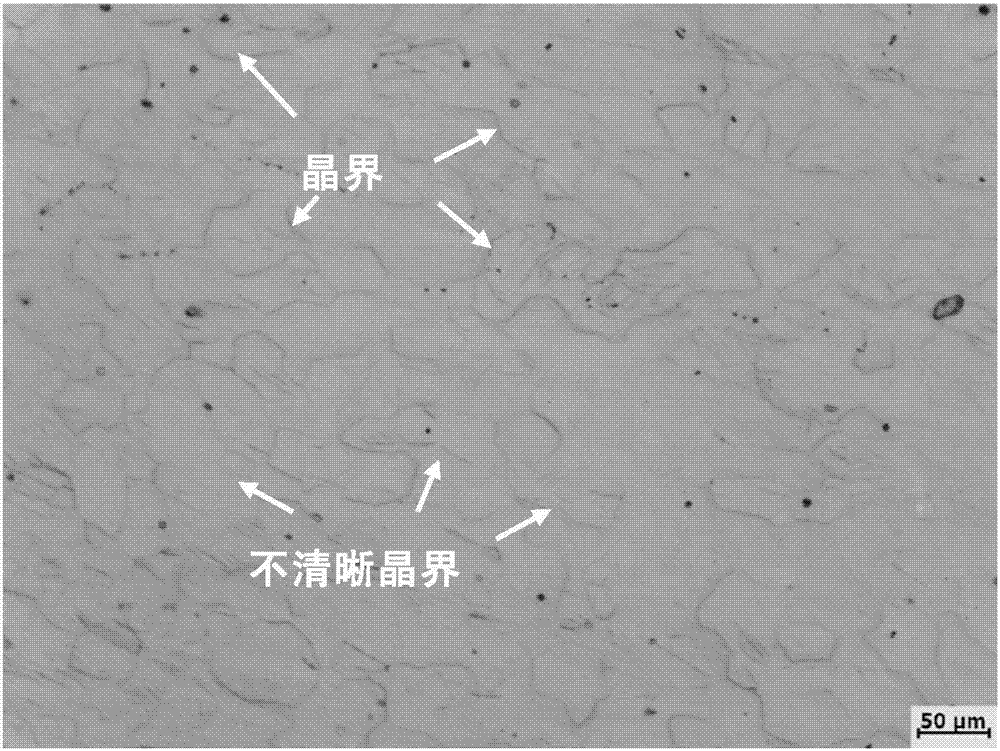

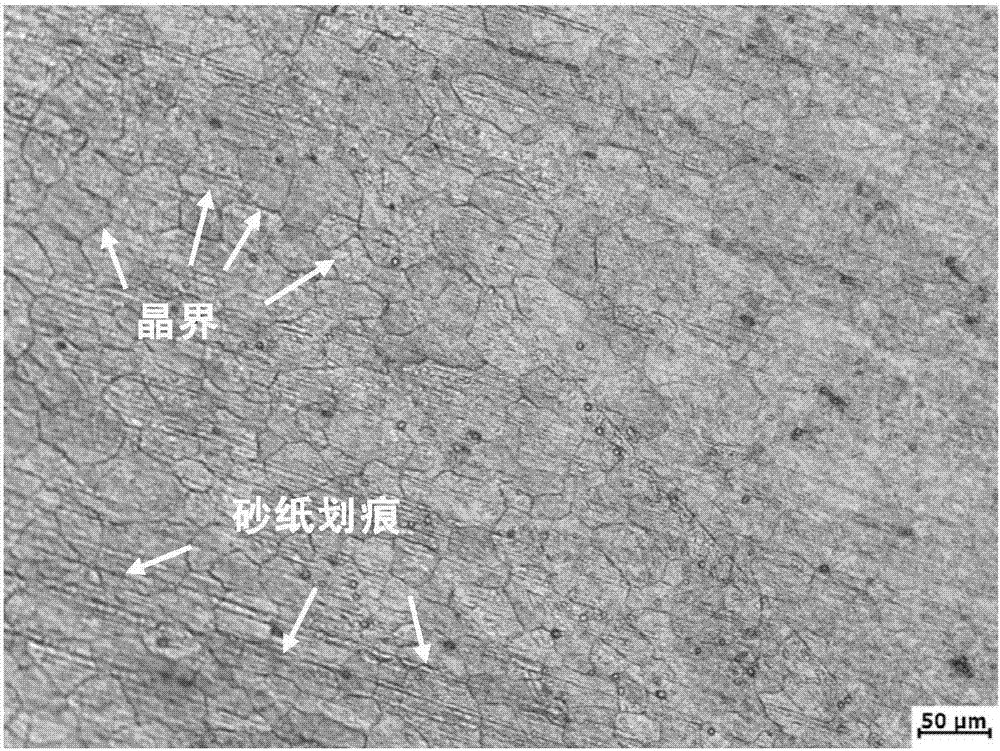

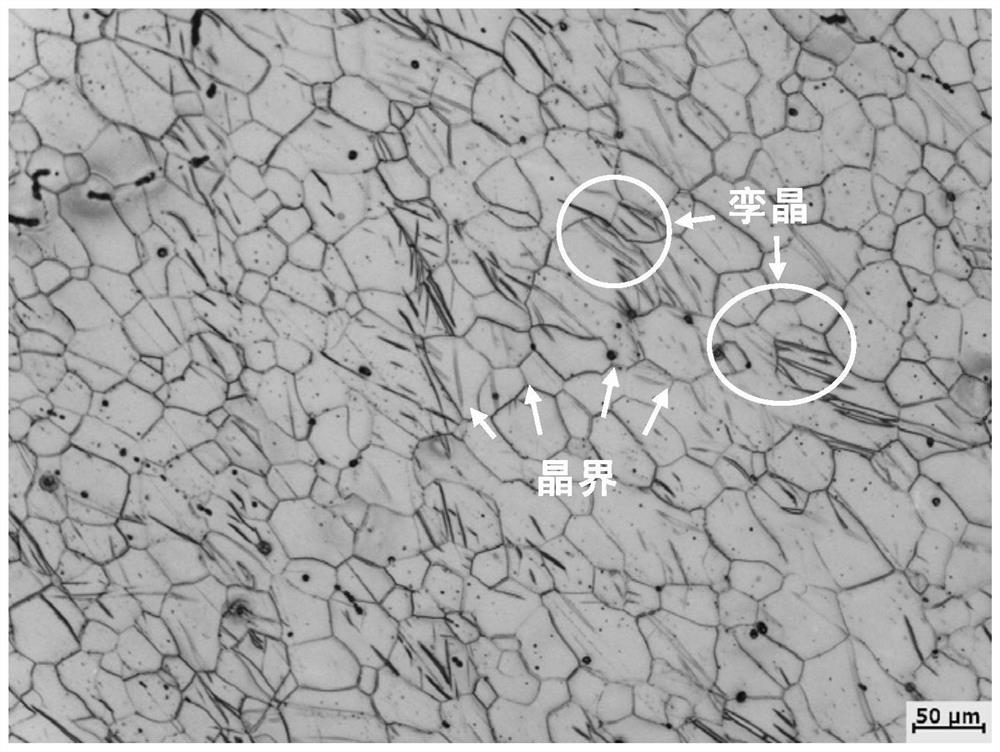

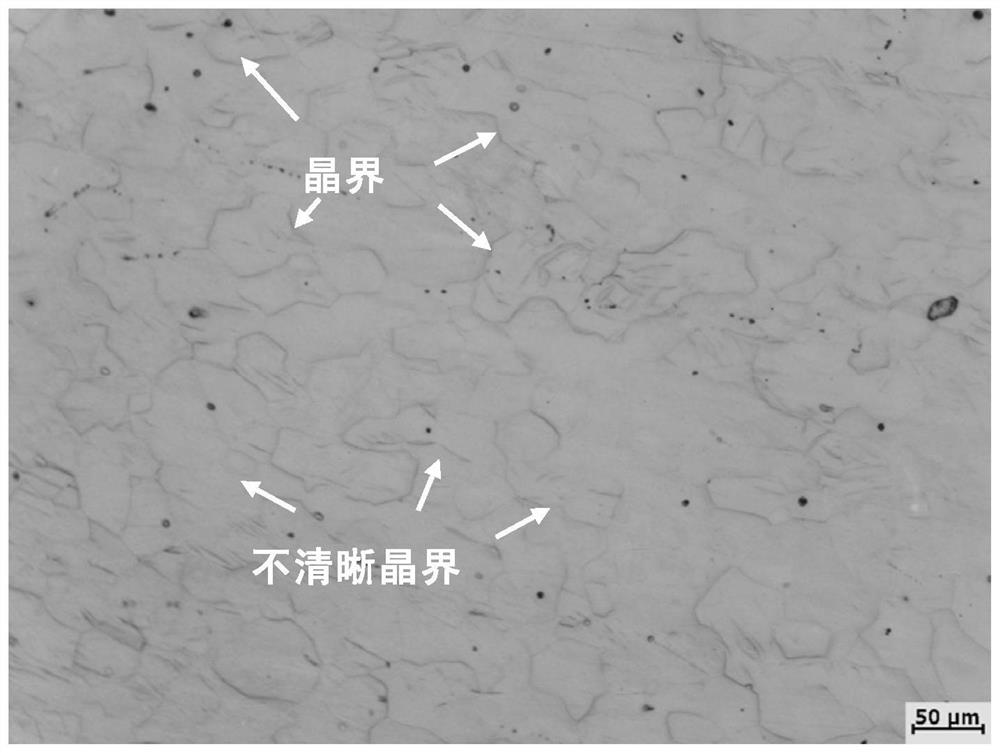

Pure magnesium metallographic tissue observation method

ActiveCN107976443AAccurately reflect the organizational formSlow corrosionPreparing sample for investigationMaterial analysis by optical meansAir blowerTwo step

The invention discloses a pure magnesium metallographic tissue observation method, which comprises the following steps of 1, sequentially using 600#, 1000#, 2000# and 5000# silicon carbide abrasive paper for performing grade-to-grade grinding on the surface of the pure magnesium to obtain a flat pure magnesium observation surface with the fine and dense scratching marks; 2, using a first corrosionagent for performing primary wiping corrosion on the pure magnesium observation surface; then, performing flushing by ethanol; next, performing dry blowing by an air blower; 3, using a second corrosion agent for performing secondary wiping corrosion on the pure magnesium observation surface subjected to the primary wiping corrosion treatment; then, performing flushing by ethanol; next, performingdry blowing by an air blower; 4, observing the blown and dried pure magnesium observation surface by a metaloscope. The abrasive paper scratch mark and dirty materials are removed through two-step wiping corrosion treatment, so that the pure magnesium metallographic tissue is clearly shown; the tissue form of the pure magnesium is accurately reflected; the process is simple; the control is easy;the method is suitable for being used for observing the metallographic structures of the pure magnesium in various forms such as the cast form, the cast rolling form, the hot rolling form and the heattreatment form.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

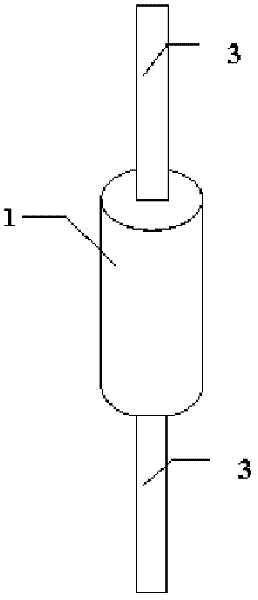

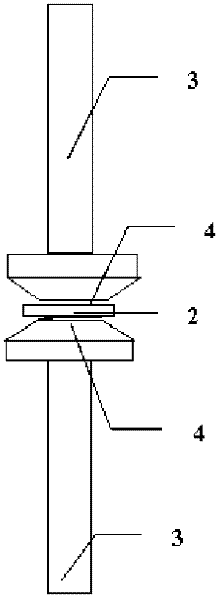

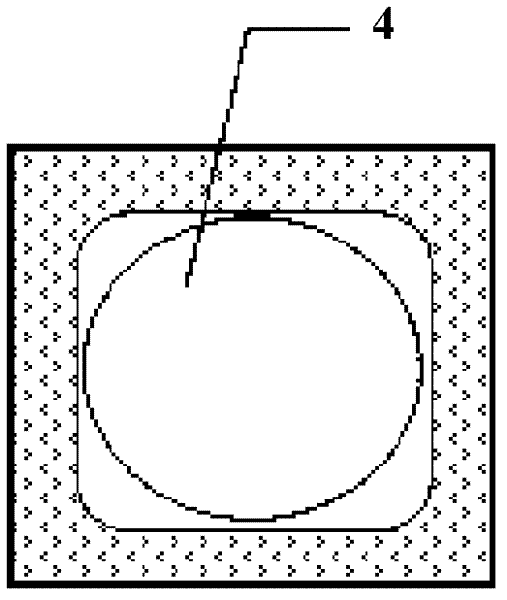

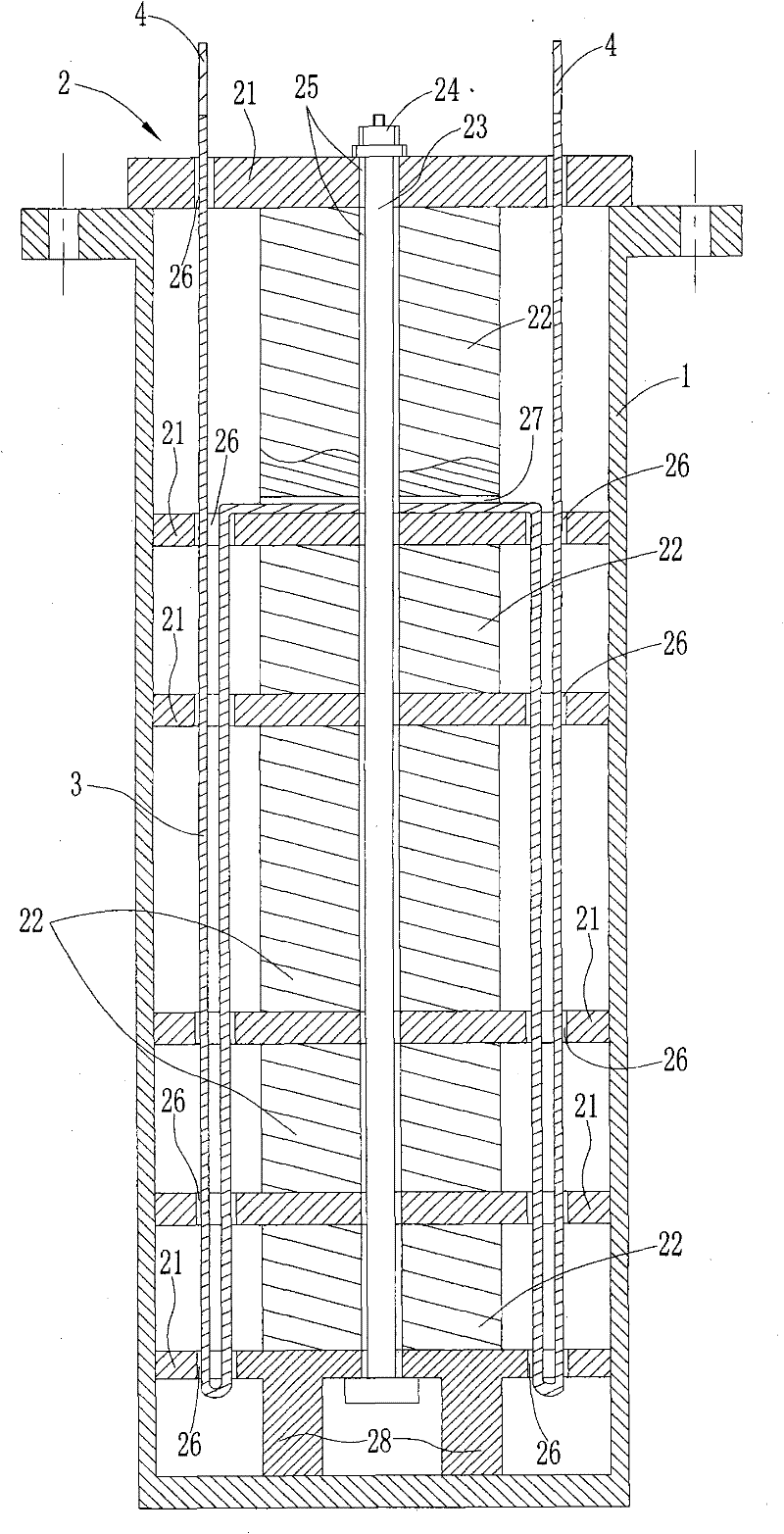

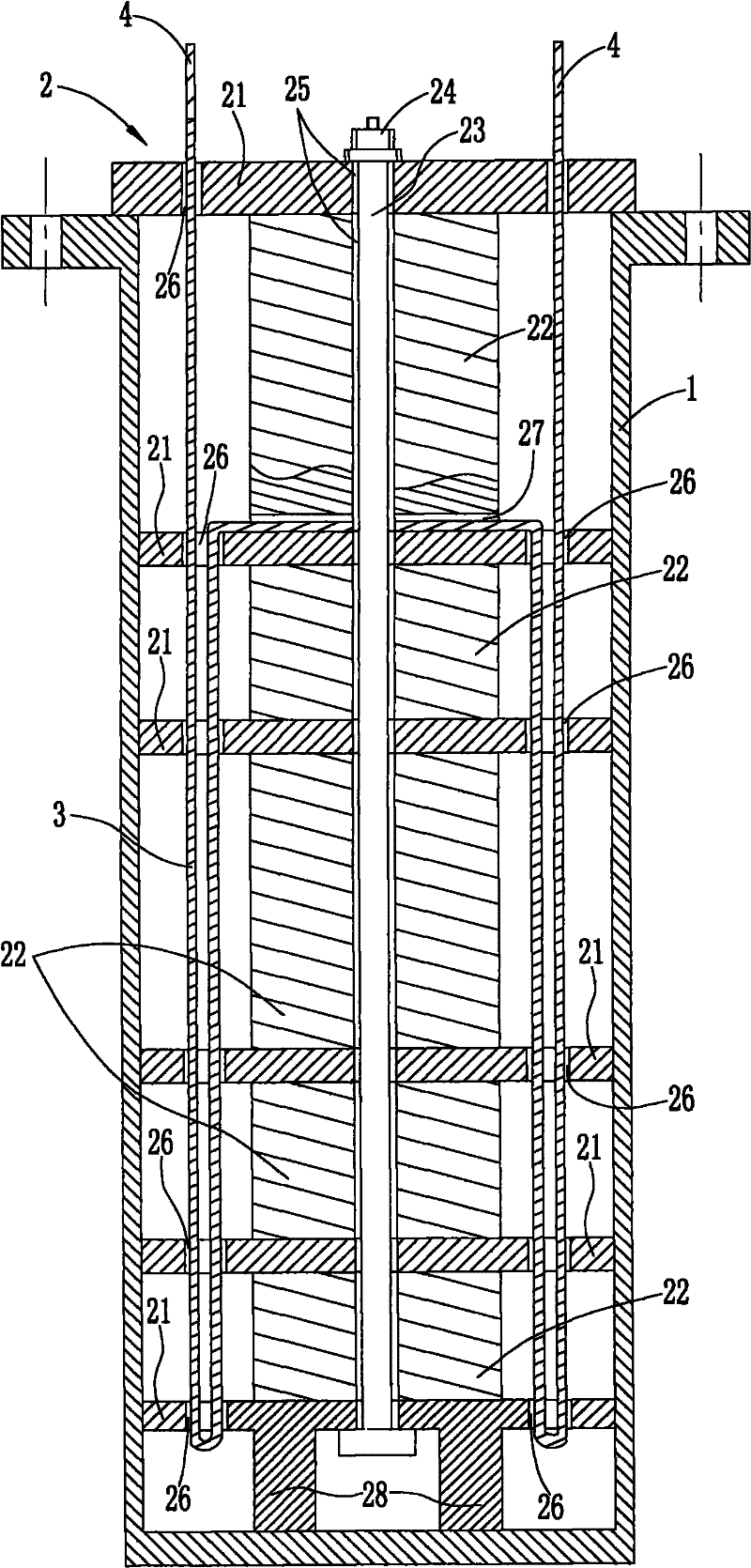

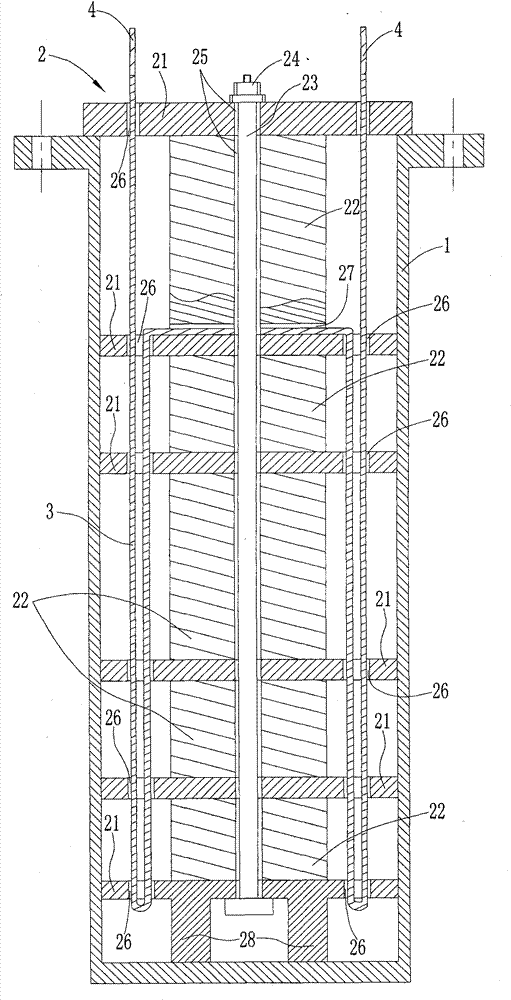

Heating device for electrochemstry cleaning salt bath furnace

ActiveCN102131321AEvenly heatedSlow corrosionImmersion heating arrangementsOhmic-resistance heating detailsCeramic bracketsMolten salt

The invention relates to a heating device, in particular to a heating device for an electrochemical cleaning salt bath furnace heater in the foundry industry. The heating device comprises a shell with an open upper end and a closed lower end, and a heating core which comprises a ceramic bracket, a resistance band and two electrode connecting columns, wherein, the ceramic bracket extends into the shell and covers the opening on the upper end of the shell; the resistance band is arranged on the ceramic bracket and two upper ends of the band are bared outside the shell; and the two electrode connecting columns are respectively welded with the two upper ends of the resistance band. When in use, the heating device is directly placed in non-oxidizing molten salt in a tank body of the salt bath furnace. By utilizing the technical proposal, the resistance band of the heating core produces heat in the shell, and then the heat is diffused into the non-oxidizing molten salt outside the device through the shell so as to evenly heat the non-oxidizing molten salt. As the heating device is directly placed in the non-oxidizing molten salt in the tank body of the salt bath furnace by utilizing a built-in heating mode, the heating device has the advantages of fast heating speed and high heat efficiency so that the tank body of the salt bath furnace is evenly heated and has the characteristics of slow corrosion speed and long service life, thus finally achieving the purposes of higher cleaning efficiency and lower cleaning cost of the electrochemical cleaning salt bath furnace.

Owner:FIRST DESIGN & RES INST MI CHINA

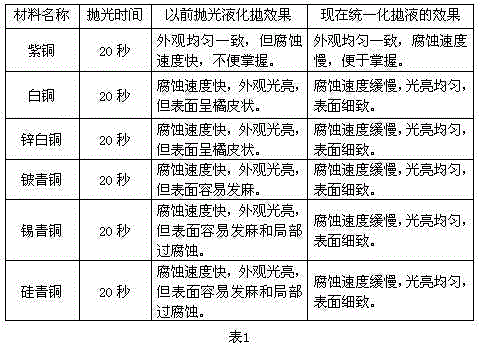

Copper or copper alloy chemical polishing liquid and preparation method thereof

The invention discloses a copper or copper alloy chemical polishing liquid which is prepared from 300-600ml / L of 92.5-98wt% concentrated sulfuric acid, 15-60ml / L of 50-70wt% nitric acid, 1-10g / L of benzotriazole methyl, 5-40g / L of lauryl sodium sulfate, 5-35ml / L of an OP emulsifier, 0.5-5g / L of sodium nitrite and the balance of water. The copper or copper alloy chemical polishing liquid disclosed by the invention is relatively simple in component, easy to operate and relatively small in atmosphere pollution. A component which is polished by using the chemical polishing liquid is uniform in surface, stable in chemical polishing quality and not easy to over-corrode, the production efficiency is greatly improved, and the production cost is lowered.

Owner:贵州振华群英电器有限公司(国营第八九一厂)

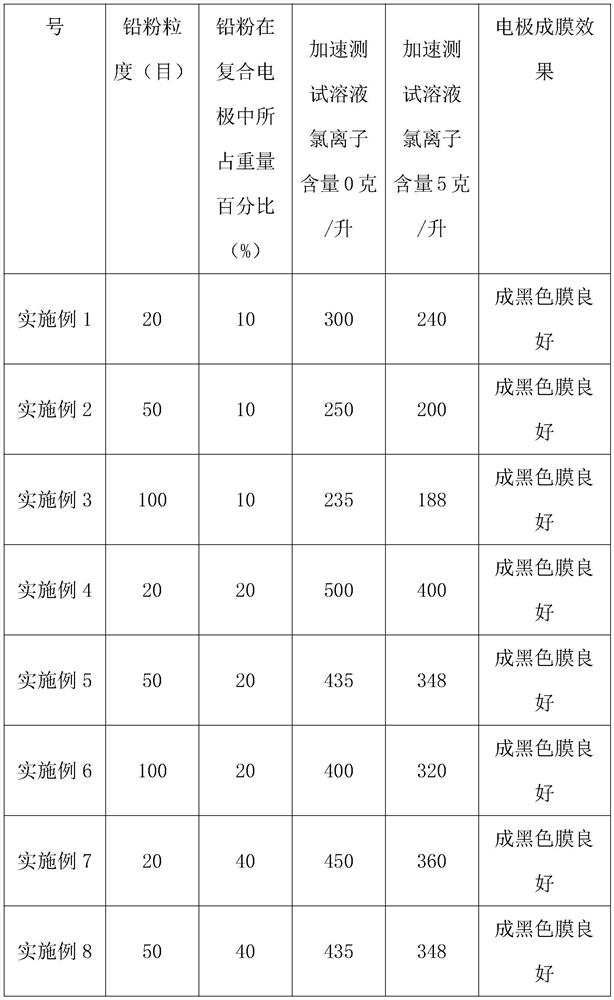

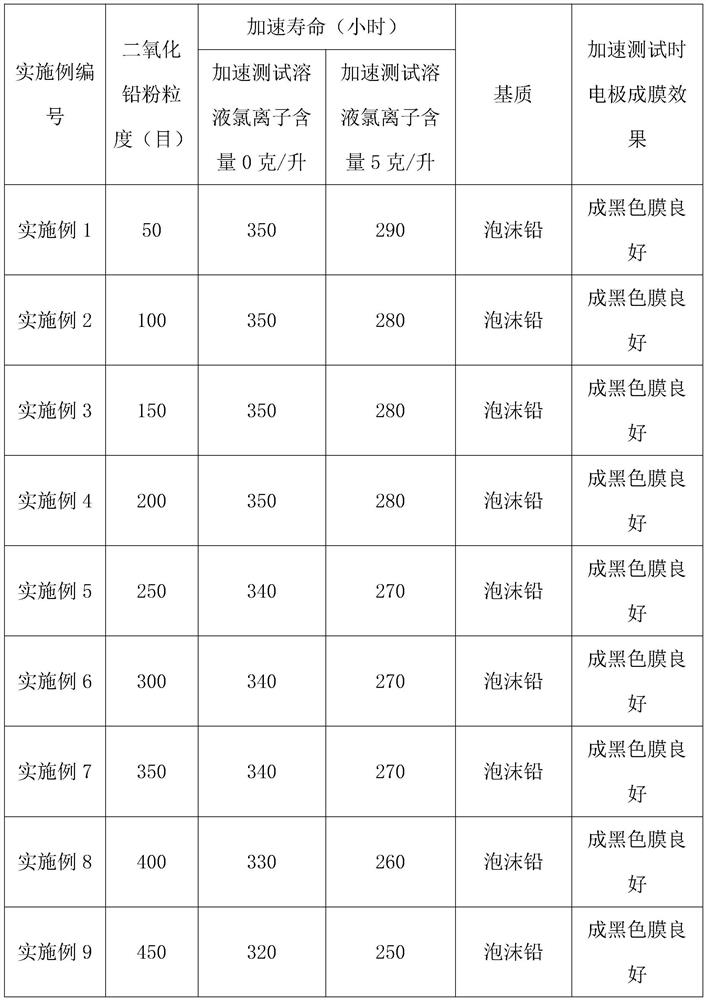

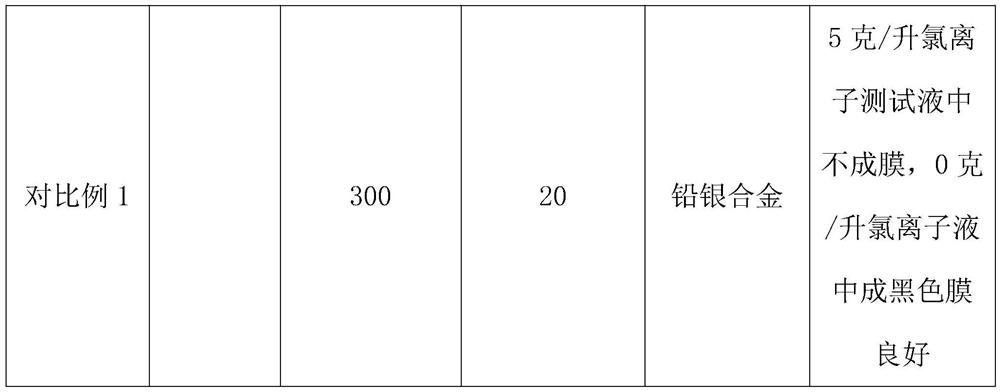

Composite lead dioxide electrode and preparation method thereof

InactiveCN112226786AEasy to useImprove corrosion resistanceAnodisationPhotography auxillary processesHigh current densityCompression molding

The invention relates to the technical field of electrodes, in particular to a composite lead dioxide electrode and a preparation method thereof. The composite lead dioxide electrode comprises a composite layer, and the composite layer is composed of the following raw materials in parts by weight: 10%-40% of lead dioxide powder, 58%-88% of lead powder paste and 0.5%-2% of antioxidant. The preparation method comprises the following preparation steps: preparation of a matrix, collection of anode mud, cleaning of the anode mud, shaping of lead dioxide powder, compression molding, product shaping,anode service life testing and chloride ion resistance testing. The composite lead dioxide electrode is long in service life and high in stability, a compact lead dioxide layer is formed when the composite lead dioxide electrode is used due to the fact that the lead dioxide powder is inserted into the metal lead, the corrosion mechanism is dissolution, the corrosion speed is low, the service lifeis long, and in the high-current-density electrolysis process, the electrode of the present invention can be stably used for a long period of time.

Owner:HUIZHOU ZHENDING ENVIRONMENTAL PROTECTION TECH CO LTD

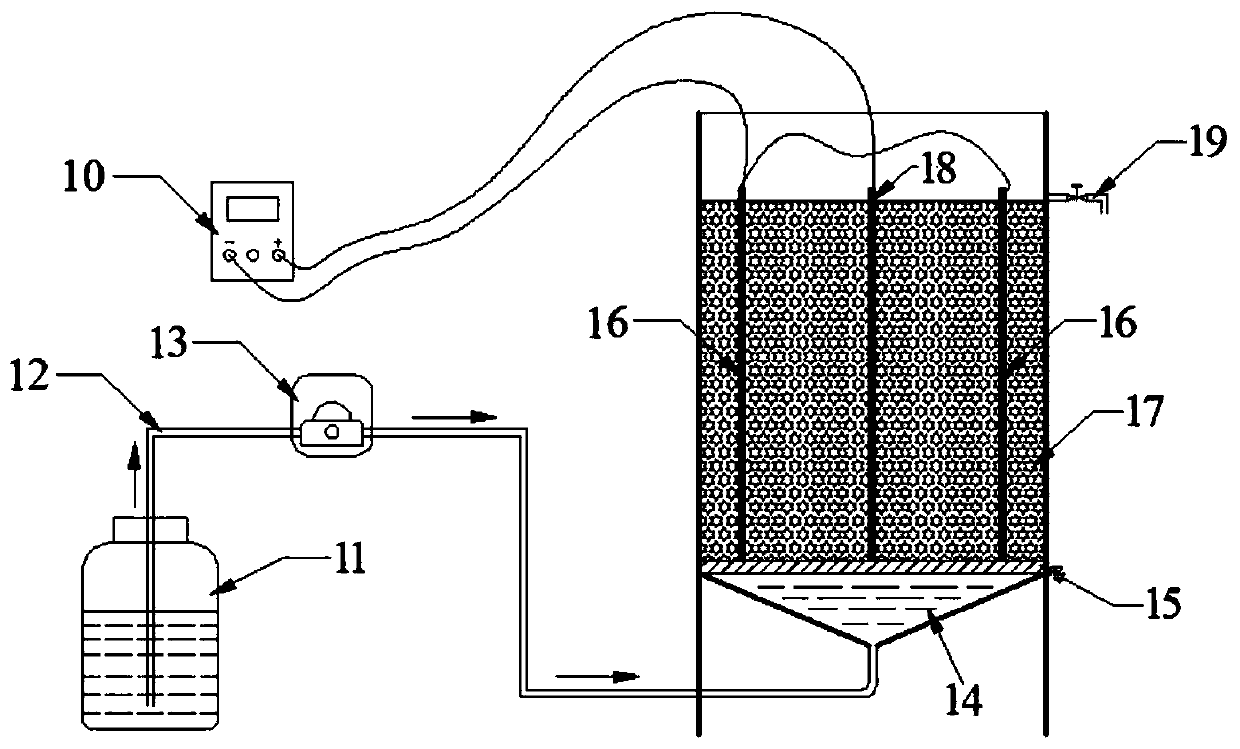

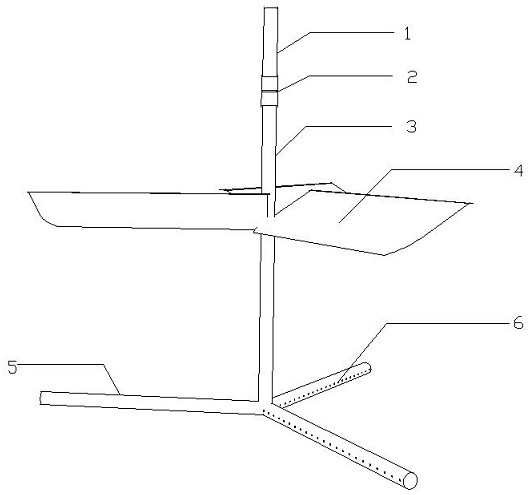

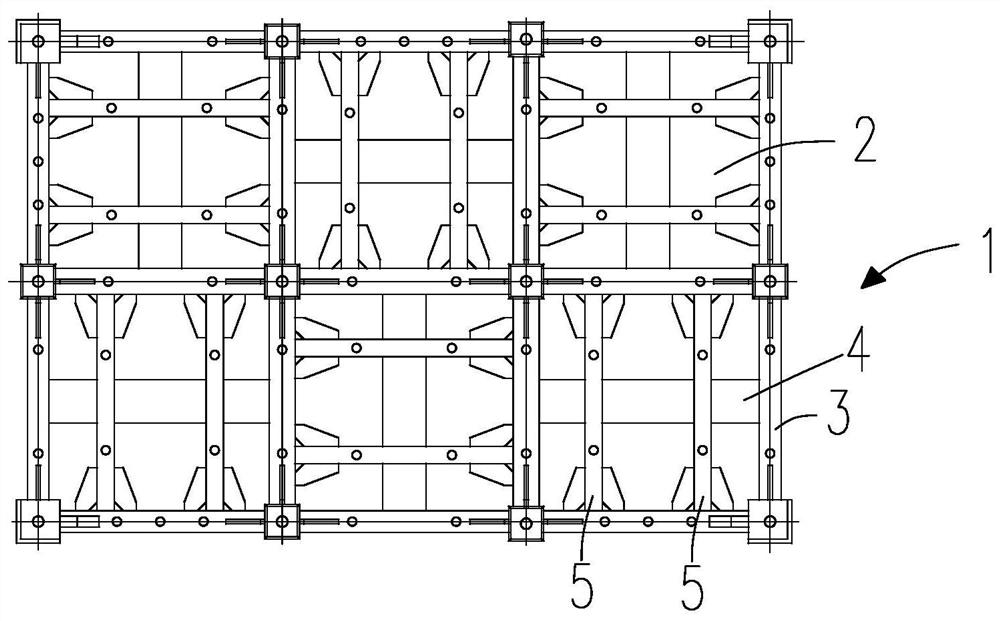

Moving bed bio-membrane reactor based on blade self-driven rotary aeration

PendingCN112678945AUniform fluidizationAvoid accumulationSustainable biological treatmentBiological water/sewage treatmentThermodynamicsMoving bed biofilm reactor

The invention provides a moving bed bio-membrane reactor based on blade self-driven rotary aeration. The moving bed bio-membrane reactor comprises a reactor body, a bearing support is arranged at the upper end of the reactor body, an air riser is arranged on the bearing support, an air inlet pipe is arranged at the upper end of the air riser, the lower end of the air riser is fixed on a plummer block II, and the plummer block II is arranged at the bottom of the reactor body. Rotary blades are further arranged on the air riser, a rotary air transverse pipe is arranged at the lower end of the air riser, and a through hole is formed in the rotary air transverse pipe. The reactor provided by the invention can promote uniform fluidization of a filler, prevent the phenomena of filler accumulation or ball death and the like, and also can prevent sludge sedimentation.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

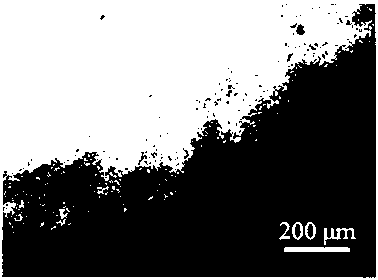

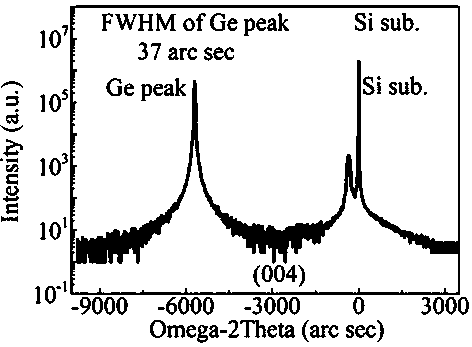

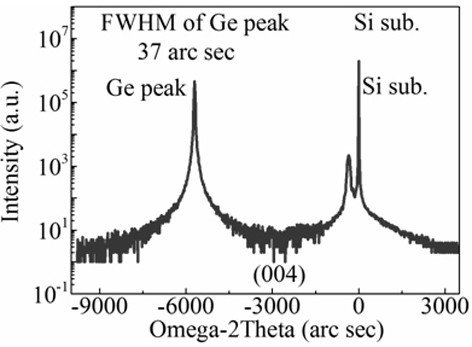

Preparation method of ultrahigh-quality SOI-based bonded Ge film

ActiveCN110660654ASlow corrosionQuality improvementSemiconductor/solid-state device manufacturingThin membraneEngineering

The invention discloses a preparation method of an ultrahigh-quality SOI-based bonded Ge film. The method comprises steps of carrying out surface treatment of a Ge substrate and an SOI substrate; sputtering a layer of a-Ge film on each of the two substrates; laminating the Ge substrate and the SOI substrate in the atmosphere, putting the bonded Ge substrate and the SOI substrate into an annealingfurnace for low-temperature thermal annealing to realize high-strength Ge / SOI bonding, and thinning and polishing the bonded Ge substrate by adopting chemical corrosion combined with chemical mechanical polishing to obtain the ultrahigh-quality SOI-based bonded Ge film.

Owner:MINNAN NORMAL UNIV +1

Heating device for electrochemstry cleaning salt bath furnace

ActiveCN102131321BEvenly heatedSlow corrosionImmersion heating arrangementsOhmic-resistance heating detailsElectrical resistance and conductanceMolten salt

The invention relates to a heating device, in particular to a heating device for an electrochemical cleaning salt bath furnace heater in the foundry industry. The heating device comprises a shell with an open upper end and a closed lower end, and a heating core which comprises a ceramic bracket, a resistance band and two electrode connecting columns, wherein, the ceramic bracket extends into the shell and covers the opening on the upper end of the shell; the resistance band is arranged on the ceramic bracket and two upper ends of the band are bared outside the shell; and the two electrode connecting columns are respectively welded with the two upper ends of the resistance band. When in use, the heating device is directly placed in non-oxidizing molten salt in a tank body of the salt bath furnace. By utilizing the technical proposal, the resistance band of the heating core produces heat in the shell, and then the heat is diffused into the non-oxidizing molten salt outside the device through the shell so as to evenly heat the non-oxidizing molten salt. As the heating device is directly placed in the non-oxidizing molten salt in the tank body of the salt bath furnace by utilizing a built-in heating mode, the heating device has the advantages of fast heating speed and high heat efficiency so that the tank body of the salt bath furnace is evenly heated and has the characteristics of slow corrosion speed and long service life, thus finally achieving the purposes of higher cleaning efficiency and lower cleaning cost of the electrochemical cleaning salt bath furnace.

Owner:FIRST DESIGN & RES INST MI CHINA

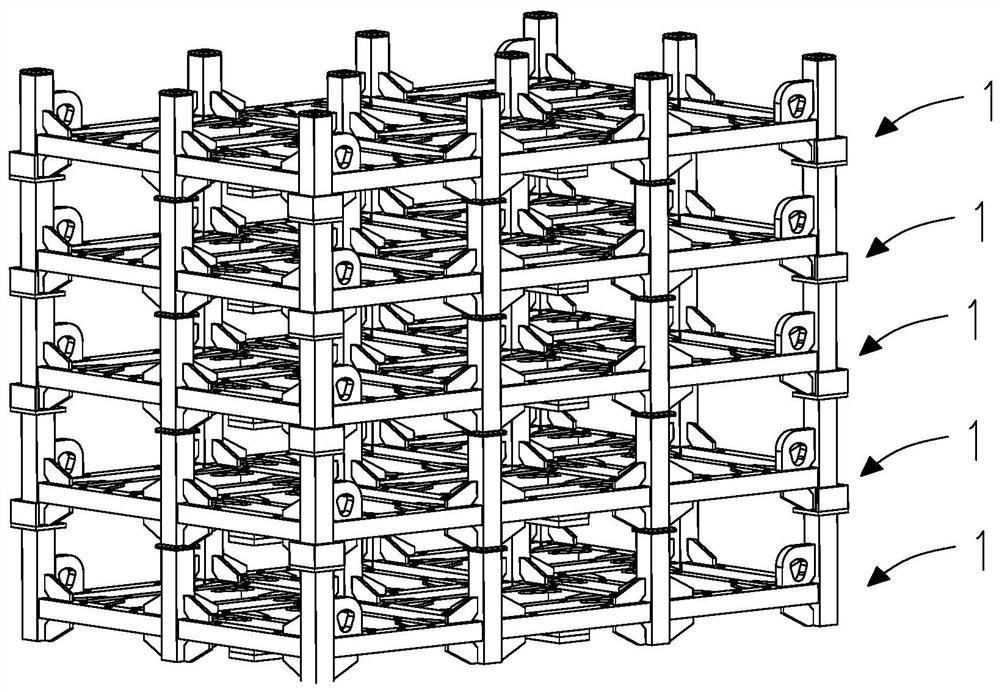

Anti-deformation heat treatment basket

The invention relates to an anti-deformation heat treatment basket. The anti-deformation heat treatment basket comprises multiple layers of detachably-connected frame bodies. Each frame body comprises multiple units which are arranged in a plane. Each unit comprises a framework, two ratchet wheel supporting pipes and a ratchet wheel supporting plate. Multiple pairs of threaded holes are formed in the framework of each unit. The two ratchet wheel supporting pipes of each unit are arranged in the corresponding framework in parallel. The end of the ratchet wheel supporting plate of each unit cooperates with one corresponding pair of threaded holes through bolts, the ratchet wheel supporting plate of each unit is fixed in the corresponding framework, and the ratchet wheel supporting plate of each unit and the corresponding ratchet wheel supporting pipes are perpendicularly arranged in different planes. The end of the ratchet wheel supporting plate of each unit cooperates with one corresponding pair of threaded holes through the corresponding bolts, so that the ratchet wheel supporting plate of each unit is fixed in the corresponding framework. Thus, the ratchet wheel supporting plates can move in the frameworks, due to the fact that unevenness of parts is different, flexible adjustment can be conducted according to the unevenness of the parts via the ratchet wheel supporting plates in the loading process, and it is guaranteed that the parts do not deform in the heat treatment process.

Owner:中铁建电气化局集团轨道交通器材有限公司

Composite lead dioxide anode and preparation method thereof

InactiveCN112095118AEasy to useImprove corrosion resistanceElectrodesCompression moldingHigh current density

The invention relates to the technical field of electrodes, in particular to a composite lead dioxide anode and a preparation method thereof. The composite lead dioxide anode comprises a supporting material and coatings, the supporting material is foamed lead, the coatings are lead dioxide coatings, and the lead dioxide coatings are arranged on the upper surface and the lower surface of the foamedlead; the preparation method comprises the following preparation steps: collecting anode mud, cleaning the anode mud, shaping lead dioxide powder, carrying out compression molding, shaping a product,testing the service life of an anode, and performing chloride ion resistance testing. The composite lead dioxide anode is long in service life and high in stability, a compact lead dioxide layer is formed when the composite lead dioxide electrode is used due to the fact that the lead dioxide powder is inserted into the metal lead, the corrosion mechanism is dissolution, the corrosion speed is low, the service life is long, and in the high-current-density electrolysis process, the composite lead dioxide electrode can be stably used for a long period of time.

Owner:HUIZHOU ZHENDING ENVIRONMENTAL PROTECTION TECH CO LTD

A method for observing the metallographic structure of pure magnesium

ActiveCN107976443BAccurately reflect the organizational formSlow corrosionPreparing sample for investigationMaterial analysis by optical meansCarbide siliconHeat treated

The invention discloses a method for observing the metallographic structure of pure magnesium. The method comprises: 1. Using 600 # 、1000 # , 2000 # and 5000 # Grind the surface of pure magnesium step by step with silicon carbide sandpaper to obtain a flat and finely scratched pure magnesium observation plane; 2. Use the first etchant to rub the pure magnesium observation surface once, then rinse it with alcohol, and then use a hair dryer 3. Use the second corrosive agent to perform secondary erosion on the observation surface of pure magnesium after the first abrasion treatment, then rinse with alcohol, and then dry it with a hair dryer; 4. Use a metallographic microscope to examine the dried pure magnesium Magnesium viewing surface for observation. The invention removes sandpaper scratches and dirt on the observation surface of pure magnesium through two-step abrasion treatment, and makes the metallographic structure of pure magnesium appear clearly, thereby accurately reflecting the structure of pure magnesium. The process is simple, easy to control, and is suitable for observation The metallographic structure of various forms of pure magnesium such as cast, cast-rolled, hot-rolled and heat-treated.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A kind of stainless steel formula specially used for crane cable block and its preparation method

Owner:杭州振华钣金有限公司

Chemical polishing solution for precision copper alloy workpieces

The invention discloses a chemical polishing solution for precision copper alloy workpieces. The chemical polishing solution is prepared from the following raw materials in parts by weight: 1000 to 1200 parts of 85 percent by weight phosphoric acid, 350 to 500 parts of 98 percent by weight sulfuric acid, 3 to 10 parts of aluminum phosphate, 10 to 30 parts of potassium peroxodisulfate, 0.1 to 0.5 part of diphenylthiourea and 3 to 5 parts of corrosion inhibitor, wherein the corrosion inhibitor is a mixture of 2-ethyl-3-5-dimethylpyrazine, thiourea, sorbitol and sulfosalicylic acid in a mass ratio of 1 to (1 to 3) to (3 to 5) to (5 to 10). Compared with the prior art, the copper alloy chemical polishing solution provided by invention is environmentally friendly, is free from yellow smoke, islow in corrosion rate, can achieve a bright mirror effect, and is particularly suitable for polishing copper alloy precision parts with strict size requirements.

Owner:惠州宇盛机械设备有限公司

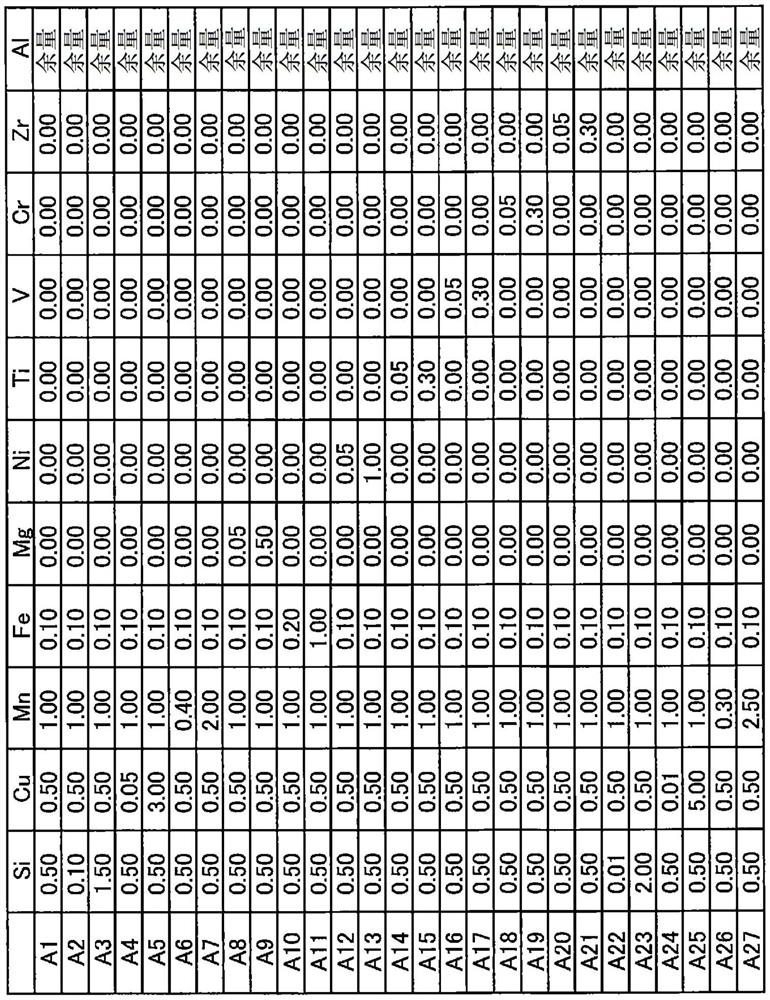

Steel for D-type anchor chain end shackle

PendingCN111172473AStrong process adaptabilityLabor intensiveUltimate tensile strengthMaterials science

The invention discloses steel for a D-type anchor chain end shackle. The steel is composed of the following elements in percentage by mass of 0.30%-0.34% of C, 0.20%-0.35% of Si, 1.70%-1.80% of Mn, 0.45%-0.55% of Cr, 0.050%-0.065% of Mo, 0.020%-0.035% of Al, 0%-0.015% of P, 0%-0.008% of S, 0.010%-0.020% of Ti, 0%-0.0020% of O, 0%-0.0002% of H, 0%-0.0070% of N and the balance Fe. The steel for theD-type anchor chain end shackle has higher strength, toughness and corrosion resistance, the application range is wider, the steel is suitable for a D-type end shackle of a common specification, and can also meet a large-specification D-type anchor chain end shackle. The steel is high in adaptability to the process, can be produced in the process flow (converter or electric furnace + furnace external refining + continuous casting + rolling) of a conventional steel enterprise, the production process is simple, and cost is low.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

A method for preparing ultra-high quality SOI-based bonded GE thin films

ActiveCN110660654BSlow corrosionQuality improvementSemiconductor/solid-state device manufacturingPhysical chemistryThin membrane

The invention discloses a method for preparing an ultra-high-quality SOI-based bonded Ge thin film, which is to sputter a layer of a-Ge thin film on the Ge sheet and the SOI sheet after surface treatment, and then place the Ge sheet in the atmosphere. The two are bonded together, placed in an annealing furnace for low-temperature thermal annealing to achieve high-strength Ge / SOI bonding, and then chemical etching combined with chemical mechanical polishing is used to thin and polish the bonded Ge wafers to obtain ultra-high Quality SOI-based bonded Ge thin films.

Owner:MINNAN NORMAL UNIV +1

Lead-calcium polar plate for storage battery, and collecting bar welding rod

InactiveCN104022254AExtended service lifeSlow corrosionCell component detailsWelding/cutting media/materialsEngineeringAntimony

The invention relates to a lead-calcium polar plate for a storage battery, and a collecting bar welding rod. The collecting bar welding rod is characterized by being prepared from the components in percentage by weight: 3.5-4.5 percent of antimony, 0.1-0.4 percent of tin, 0.02-0.08 percent of arsenic and the balance being lead. With the adoption of the collecting bar welding rod, the phenomena of faulty welding and false welding are not easy to occur, the welding quality is good, and the service life of the storage battery is relatively long.

Owner:LIUZHOU DONGLIBAO POWER SUPPLY TECH

Valuable metal leaching system and leaching method in a kind of waste lithium battery

ActiveCN107863583BReduce concentrationThe reduction effect is stableWaste accumulators reclaimingProcess efficiency improvementMetal leachingEnvironmental engineering

The invention belongs to the field of waste battery resource recycling, and discloses a leaching system and leaching method for valuable metal in a waste lithium battery. According to the leaching method, a sulfamic acid-glucose leaching agent is pre-heated, positive electrode powder is added, and stirring and leaching in a reaction kettle are performed, Co (III) and Mn (IV) are reduced to Co (II)and Mn (II) which are dissolved in a leaching liquid with Li<+> and Ni<2+>, Li, Co, Ni and Mn leaching rate in the waste battery positive electrode powder can reach 95% or above, and recycling or reusing of Li, Co, Ni and Mn can be achieved after further processing the leaching liquid. Compared with a traditional leaching liquid, the leaching system has the advantages of greenness, environmentalfriendliness, safe and controllable leaching process and relatively good industrial application prospect.

Owner:CENT SOUTH UNIV +1

Aluminum alloy heat exchanger for exhaust gas recirculation system

InactiveCN111918977ASlow corrosionSolution to short lifeExhaust gas recirculationCorrosion preventionExhaust gas recirculationCorrosion

Provided is an aluminum alloy heat exchanger for exhaust gas recirculation system, obtained by brazing a fin material onto a tube material. The fin material comprises: an aluminum alloy core materialcontaining 0.10-1.50% Si and 0.40-2.00% Mn, and having a Zn content of less than 0.05%; and a brazing material clad on both sides of the core material, and made from an aluminum alloy containing 3.00to 13.00% Si and having a Zn content of less than 0.05%. The tube material comprises at least: an aluminum alloy core material containing 0.10-1.50% Si, 0.05-3.00% Cu and 0.40-2.00% Mn; and a sacrificial anti-corrosion material clad on the inner surface of said core material and comprising an aluminum alloy which contains 2.00-6.00% Zn and which has a Si content of less than 0.10%. According to this invention it is possible to provide an aluminum alloy heat exchanger for exhaust gas recirculation system, having slow corrosion and long service life in an ammonium environment in which ammonium is contained in condensate water of exhaust gas.

Owner:FURUKAWA SKY ALUMINUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com