Copper or copper alloy chemical polishing liquid and preparation method thereof

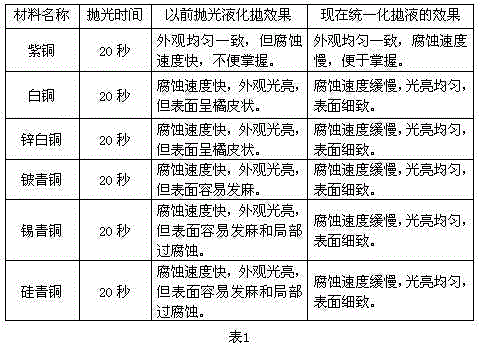

A chemical polishing and copper alloy technology, applied in the field of chemical polishing liquid and its preparation, can solve the problems of increasing production cost and sewage treatment cost, shortening the service life of chemical polishing liquid, unstable hydrogen peroxide, etc., so as to achieve easy control of the corrosion process , chemical polishing quality is stable, and the surface of parts is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1. 1 liter of copper or copper alloy chemical polishing solution, take 300-600ml of 92.5-98wt% concentrated sulfuric acid, 15-60ml of 50-70wt% nitric acid, 1-10g of phenylproprazole, dodecyl sulfuric acid Sodium 5~40g, OP emulsifier 5~35ml, sodium nitrite 0.5~5g and enough water are prepared according to the following steps:

[0020] a. Measure 350ml of water to obtain product A;

[0021] b. Slowly add 300-600 ml of concentrated sulfuric acid with 92.5-98wt% sulfuric acid to product A while stirring, and wait until the temperature drops to 50-60°C to obtain product B;

[0022] c. Slowly add 15-60ml of 50-70wt% nitric acid to product B and stir continuously to obtain product C;

[0023] d. Add 1-10 g of phenylproprazole to product C under stirring to obtain product D;

[0024] e. Add 5-40g of sodium lauryl sulfate into product D under stirring to obtain product E;

[0025] f. Add 5~35ml OP emulsifier to product E under stirring to obtain product F;

[0026] g. Add 0.5~5g of...

Embodiment 2

[0028] Example 2. 1 liter of copper or copper alloy chemical polishing liquid, take 400-500ml of 92.5-98wt% concentrated sulfuric acid, 25-50ml of 50-70wt% nitric acid, 3-5g of phenylproprazole, dodecyl sulfuric acid Sodium 10~30g, OP emulsifier 10~20ml, sodium nitrite 0.5~1.5g and sufficient water are prepared according to the steps of Example 1.

Embodiment 3

[0029] Example 3. 1 liter of copper or copper alloy chemical polishing liquid, take 350ml of 92.5~98wt% concentrated sulfuric acid, 35ml of 50~70wt% nitric acid, 4g phenyltriazole, 20g sodium lauryl sulfate, OP emulsifier 15ml, 1g sodium nitrite and enough water are prepared according to the steps of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com