Aluminum alloy heat exchanger for exhaust gas recirculation system

A recirculation system, aluminum alloy technology, applied in the direction of exhaust gas recirculation, charging system, manufacturing tools, etc., to achieve the effect of long life and slow corrosion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

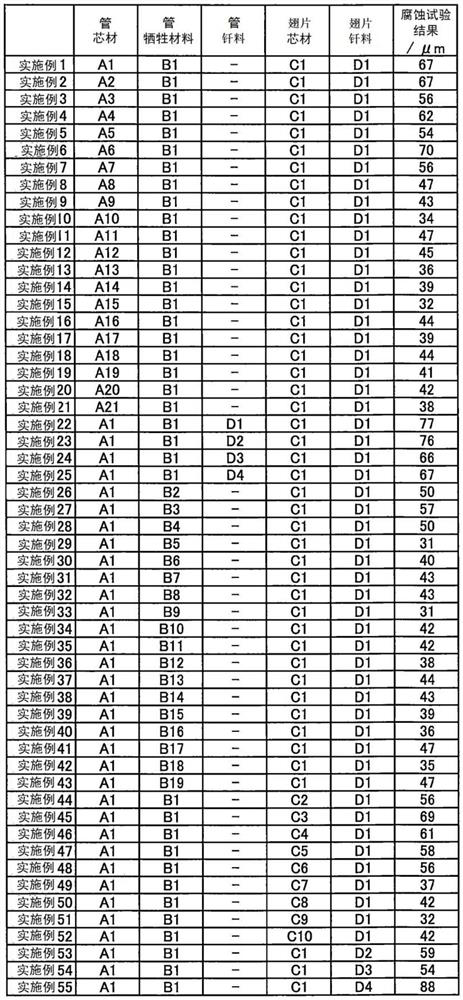

[0077] (Example and Comparative Example)

[0078]

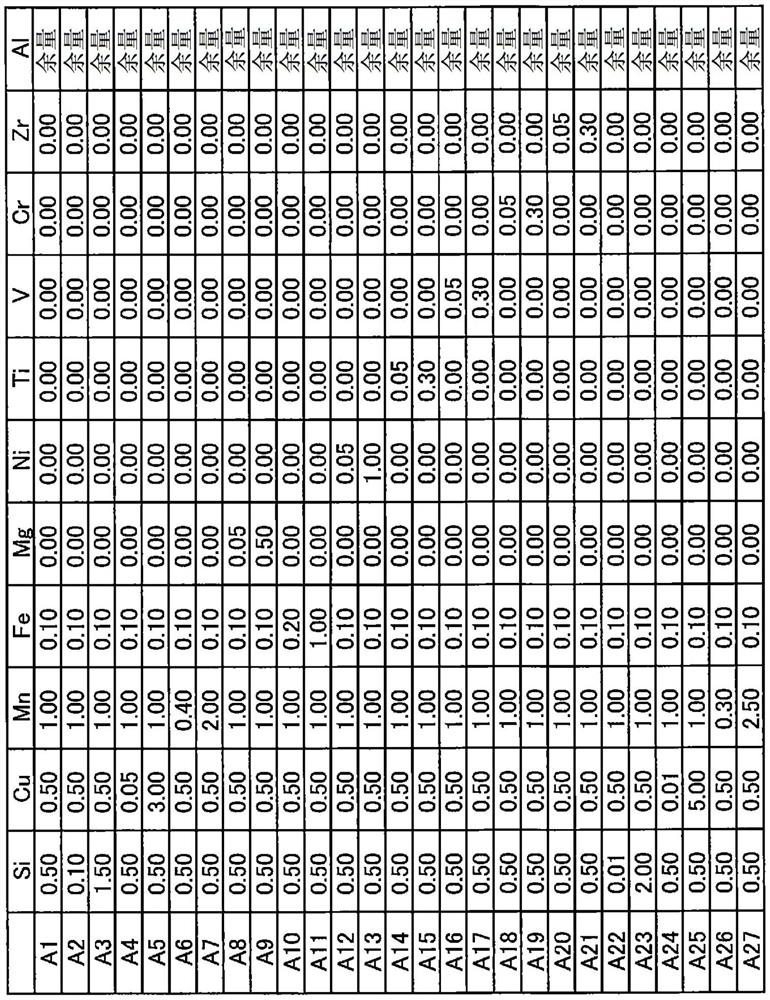

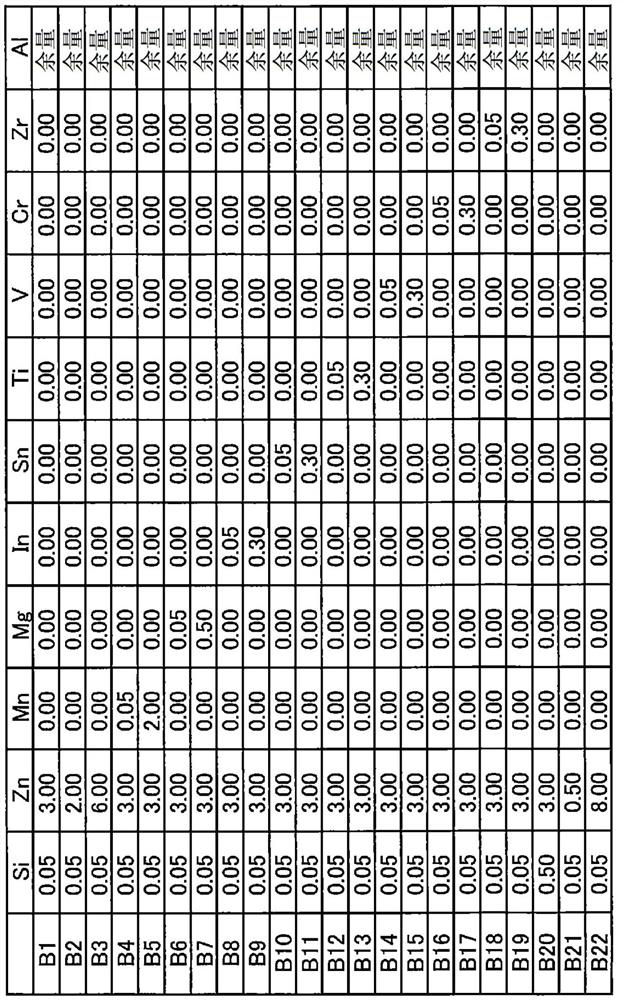

[0079] Aluminum alloy ingots for pipe core material, sacrificial anti-corrosion material, and brazing filler metal with the compositions shown in Tables 1 to 3 were separately cast by semi-continuous casting, chamfered, and homogenized at 520°C for 6 hours. deal with.

[0080] Next, according to the combination shown in Table 5, the ingot for the sacrificial anti-corrosion material was stacked on one side of the ingot for the core material, and the ingot for the brazing material was stacked on the opposite side when the brazing filler metal was also clad. Create stacked ingots. It should be noted that the thicknesses of the sacrificial anti-corrosion material and the brazing filler metal were adjusted so that the cladding ratios became 10% respectively.

[0081] Next, the stacked ingots were heat-treated to 520° C. before the hot rolling forming process, and immediately hot-rolled to produce a 3.5 mm-thick double-layer or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com