Steel for D-type anchor chain end shackle

An end shackle and anchor chain technology, which is applied in the field of alloy steel and D-type anchor chain end shackle steel, can solve the problem of not mentioning the mechanical properties of large-size steel, and cannot meet the performance requirements of large-size D-type end shackles. The mechanical properties cannot meet the problems such as anchor chain shackle, etc., to achieve the effect of increasing the labor intensity of workers, using large specifications and suitable margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Raw materials are configured by the chemical elements of the following mass percentages:

[0036] C0.32%, Si0.28%, Mn1.76%, Cr0.52%, Mo0.064%, Al0.023%, P0.012%, S0.004%, Ti0.015%, O0.0013%, H0.00016%, N0.0041%, and the balance is Fe.

[0037] Prepare the steel for D-type anchor chain end shackles according to the following process:

[0038] After smelting in ordinary converter or electric furnace, refining treatment is carried out in LF refining furnace and vacuum furnace. After LF refining, conventional calcium denaturation treatment is carried out, and it is cast into square billet or large round billet on arc continuous casting machine. Rolled into the corresponding specifications in the rolling mill;

[0039] specific:

[0040] (1) Smelting: Smelting in a converter or electric furnace of more than 50 tons, adding molten iron and scrap steel to realize dephosphorization and alloying of molten steel;

[0041] (2) Refining outside the furnace (LF furnace refining ...

Embodiment 2

[0051] Raw materials are configured by the chemical elements of the following mass percentages:

[0052] C0.30%, Si0.23%, Mn1.72%, Cr0.46%, Mo0.052%, Al0.025%, P0.009%, S0.003%, Ti0.013%, O0.0011%, H0.00008%, N0.0032%, and the balance is Fe.

[0053] The preparation process is the same as in Example 1.

[0054] In this embodiment, the specifications of the prepared steel are: casting section: 200mm*200mm, and rolled steel specification: Ф80mm.

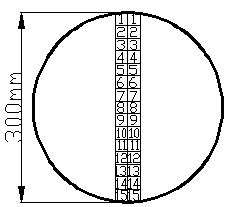

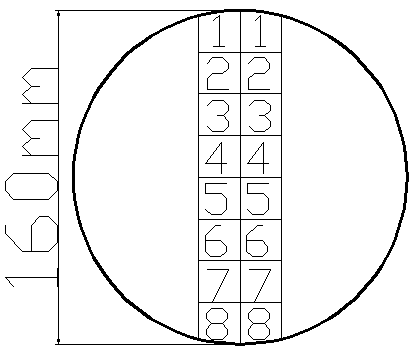

[0055] The whole raw material is quenched and tempered, the quenching and tempering temperature is 900°C quenching + 600°C tempering, the sampling position see image 3 , the obtained mechanical properties are shown in Table 3.

[0056] Table 3 Mechanical properties of raw materials

[0057]

Embodiment 3

[0059] Raw materials are configured by the chemical elements of the following mass percentages:

[0060] C0.31%, Si0.26%, Mn1.74%, Cr0.48%, Mo0.054%, Al0.026%, P0.0010%, S0.004%, Ti0.016%, O0.0013%, H0.00013%, N0.0045%, and the balance is Fe.

[0061] The preparation process is the same as in Example 1.

[0062] In this embodiment, the specifications of the produced steel are: casting section: 150mm*150mm, and rolled steel specification: Ф35mm.

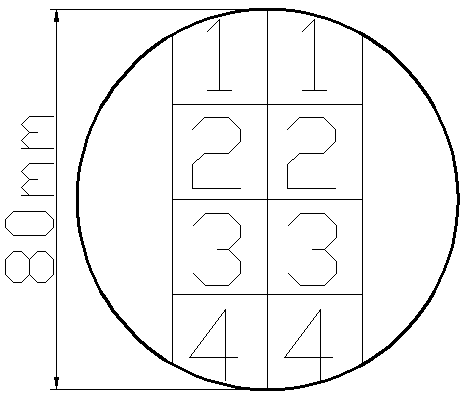

[0063] The whole raw material is quenched and tempered, the quenching and tempering temperature is 910°C quenching + 610°C tempering, the sampling position see Figure 4 , the obtained mechanical properties are shown in Table 4.

[0064] Table 4 Mechanical properties of raw materials

[0065]

[0066] The steel produced in Example 1 is hot-forged into a D-type anchor chain end shackle with a specification of Φ180mm, and the shackle has been subjected to overall quenching and tempering treatment (quenching temperature 890°C + te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com