A method for observing the metallographic structure of pure magnesium

A technology of metallographic structure and pure magnesium, which is applied in the field of microstructure observation of metal materials, can solve the problems of difficult metallographic structure, difficulty in clearly observing the metallographic structure of pure magnesium, and poor corrosion effect, so as to reduce dust pollution and energy consumption , easy to promote and use, and shorten the observation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

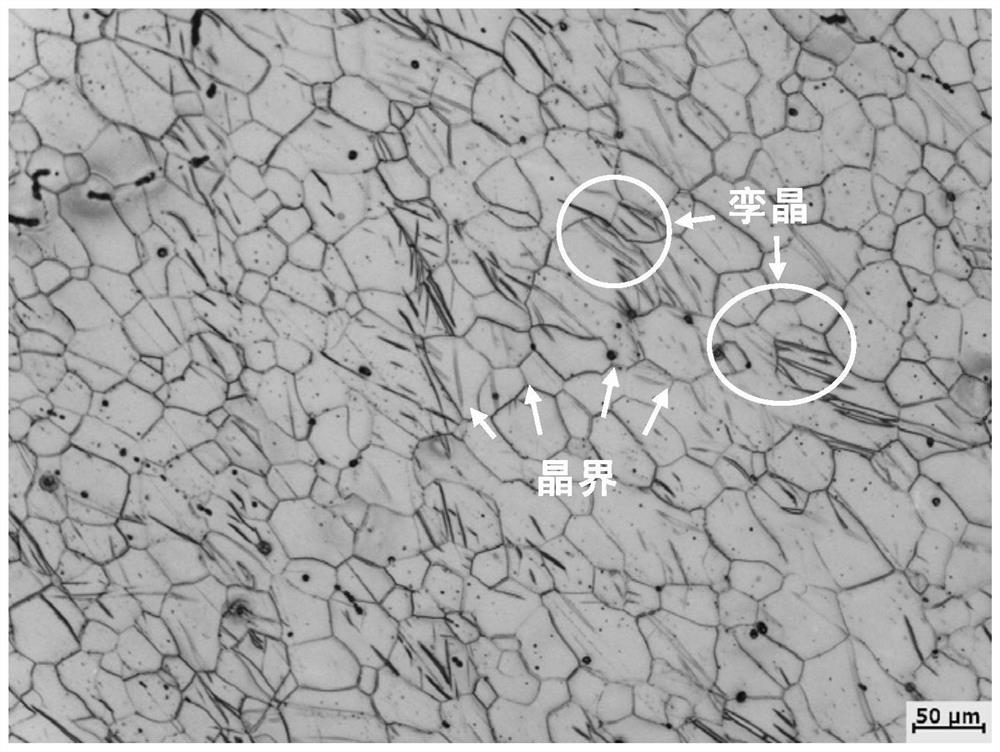

Embodiment 1

[0024] This embodiment includes the following steps:

[0025] Step 1. Use 600 sequentially # 、1000 # , 2000 # and 5000 # Silicon carbide sandpaper is used to grind the surface of hot-rolled pure magnesium step by step to obtain a flat, scratched and fine-grained observation plane of hot-rolled pure magnesium; in the step-by-step grinding process, after each replacement of silicon carbide sandpaper, heat The observation plane of rolled pure magnesium is rotated 90° and then ground until the scratches of the previous grinding are removed;

[0026] Step 2. Use the first corrosive agent to etch the hot-rolled pure magnesium observation surface obtained in step 1 once, then rinse with alcohol, and then blow dry with a hair dryer; the first corrosive agent is calculated by volume by 5 parts by mass concentration It is composed of 68% nitric acid and 95 parts of water; the time of the first abrasion is 30s;

[0027] Step 3: Use the second etchant to perform secondary erosion on ...

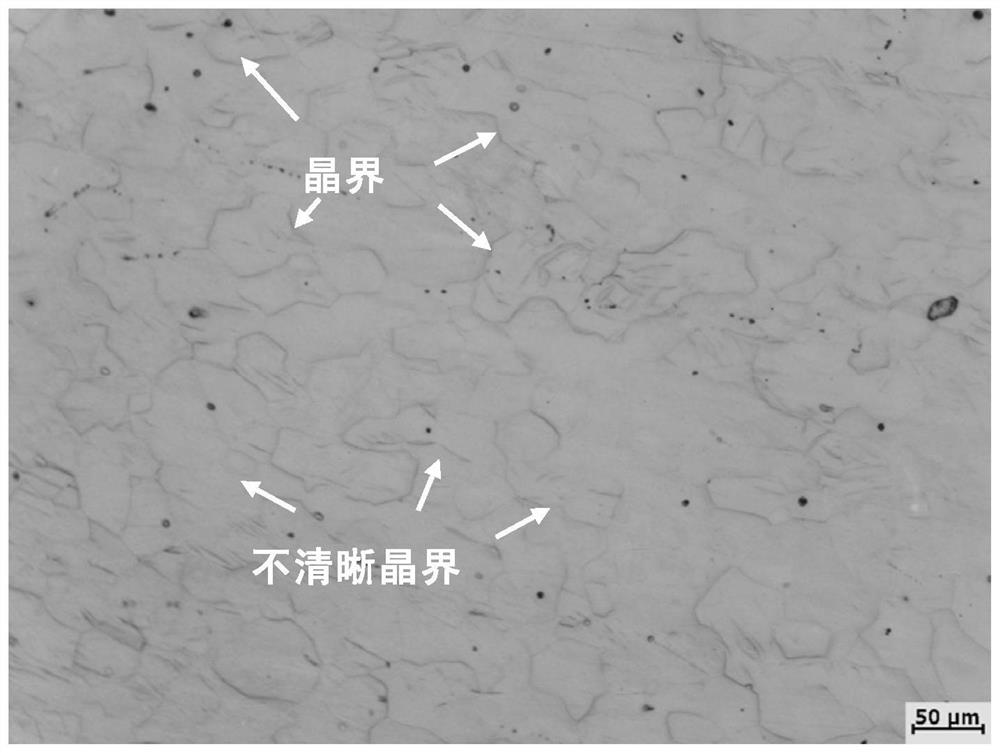

Embodiment 2

[0044] This embodiment includes the following steps:

[0045] Step 1. Use 600 sequentially # 、1000 # , 2000 # and 5000 #Silicon carbide sandpaper is used to grind the surface of as-cast pure magnesium step by step to obtain a flat, scratched and fine-grained observation plane of as-cast pure magnesium; in the step-by-step grinding process, after each replacement of silicon carbide sandpaper, the cast pure magnesium The magnesium observation plane is rotated 90° and then ground until the scratches from the previous grinding are removed;

[0046] Step 2, using the first corrosive agent to scratch the cast pure magnesium observation surface obtained in step 1, then rinse it with alcohol, and then dry it with a hair dryer; the first corrosive agent is calculated by volume by 5 parts by mass concentration. The nitric acid of 68% and the water of 95 parts are formed; The time of described one abrasion is 30s;

[0047] Step 3, using the second corrosive agent to carry out second...

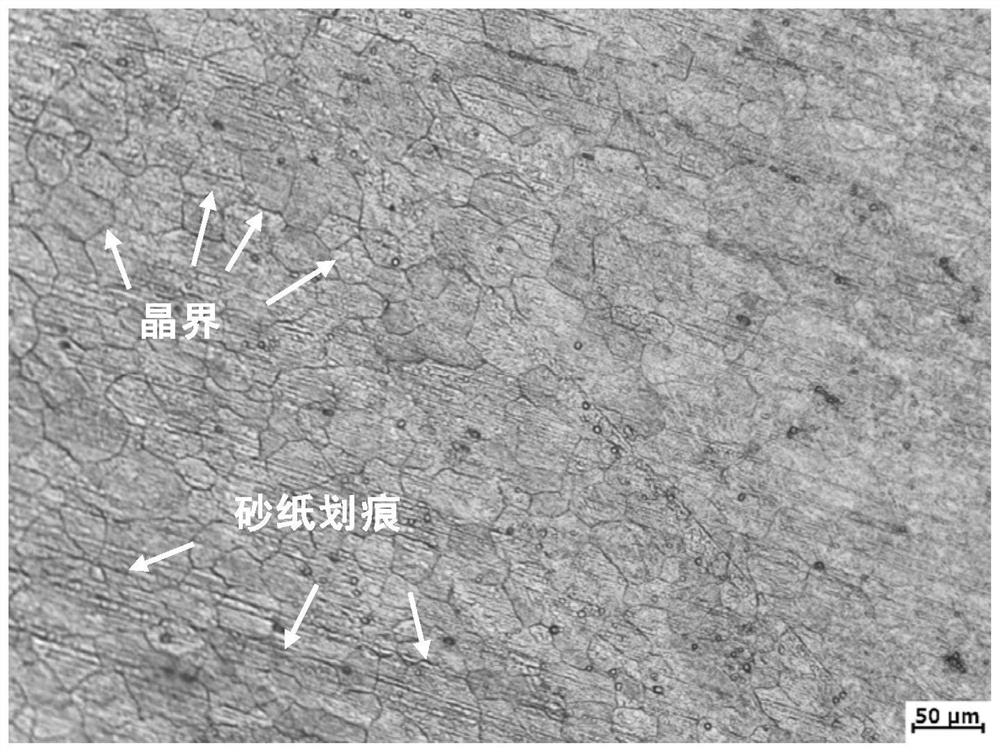

Embodiment 3

[0051] This embodiment includes the following steps:

[0052] Step 1. Use 600 sequentially # 、1000 # , 2000 # and 5000 # Silicon carbide sandpaper is used to grind the surface of cast-rolled pure magnesium step by step to obtain a flat, finely scratched pure magnesium observation plane; in the step-by-step grinding process, after each replacement of silicon carbide sandpaper, the cast-rolled pure magnesium The magnesium observation plane is rotated 90° and then ground until the scratches from the previous grinding are removed;

[0053] Step 2. Use the first corrosive agent to etch the cast-rolled pure magnesium observation surface obtained in step 1 once, then rinse with alcohol, and then dry it with a hair dryer; the first corrosive agent is calculated by volume by 5 parts by mass concentration It is composed of 68% nitric acid and 95 parts of water; the time of the first abrasion is 25s;

[0054] Step 3: Use the second etchant to perform secondary erosion on the observa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com