Heating device for electrochemstry cleaning salt bath furnace

A technology of heating device and salt bath furnace, which is applied in the direction of immersion heating device and ohmic resistance heating parts, etc., which can solve the problem of uneven heating of the salt bath furnace tank, slow heating speed, and low cleaning efficiency of electrochemical cleaning salt bath furnace And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by way of implementation and accompanying drawings:

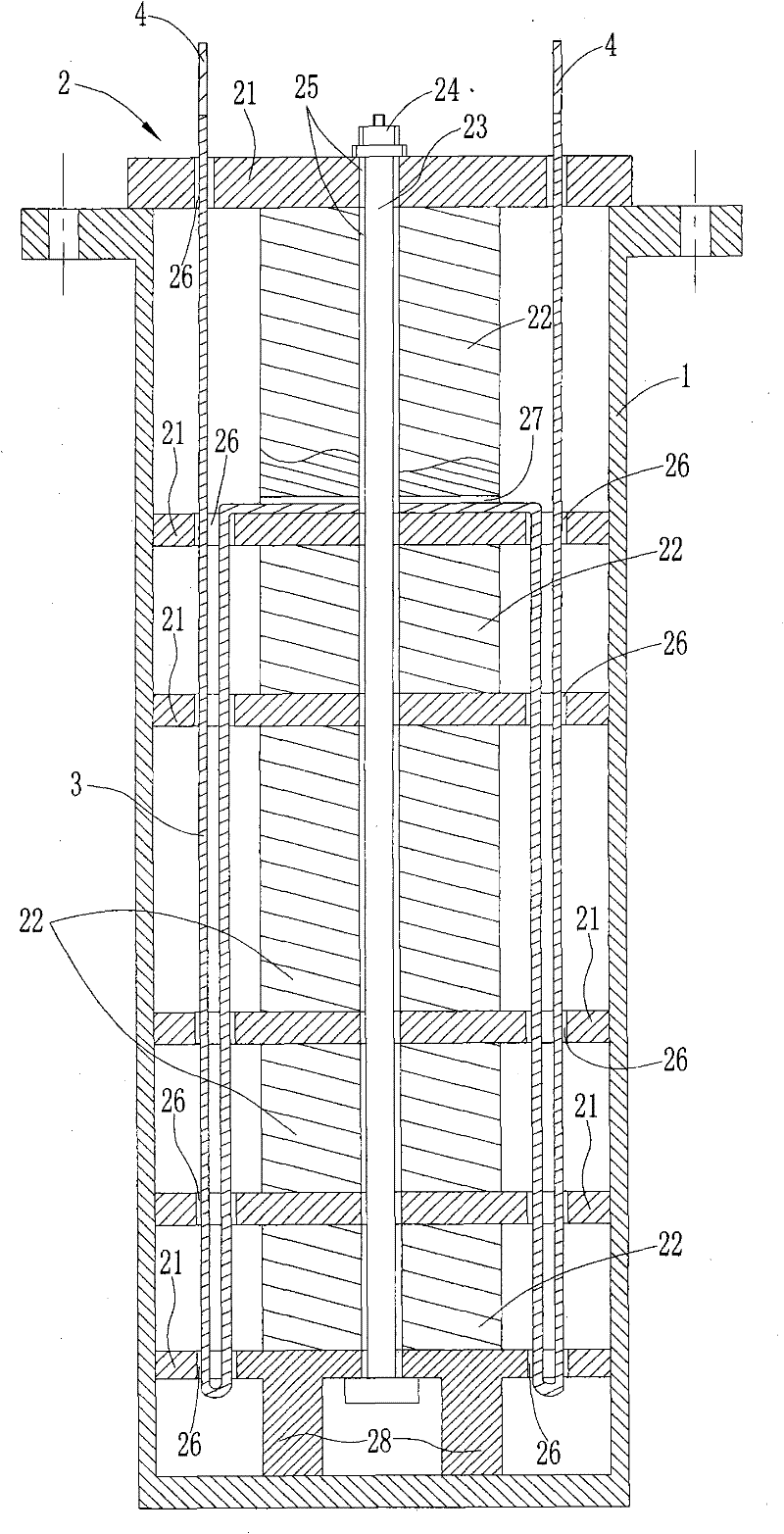

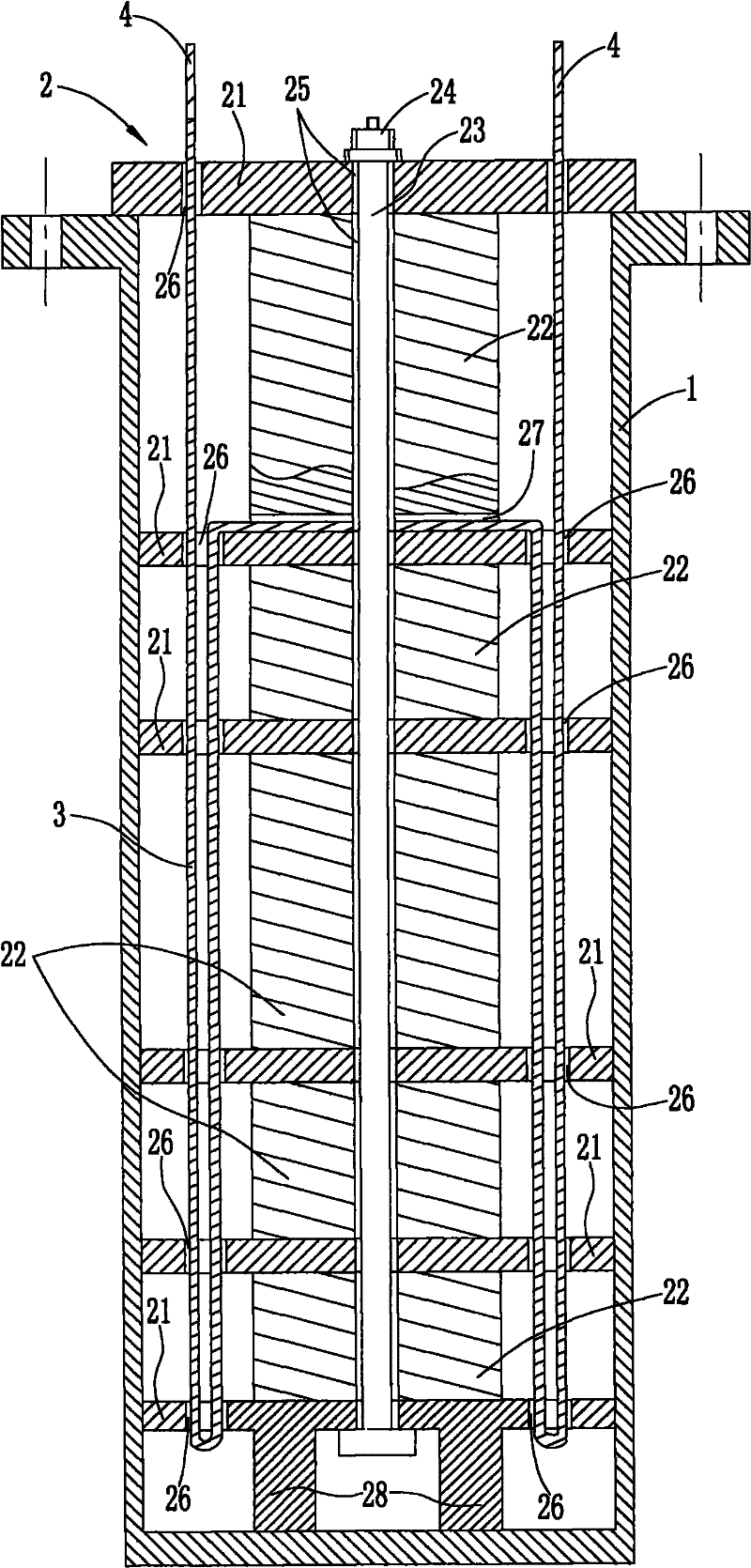

[0019] see figure 1 : the device comprises a housing 1 with an open upper end and a closed lower end, and a heating core. The heating core includes a ceramic bracket 2 that protrudes into the housing 1 and covers the upper end of the housing 1, a resistance band 3 that is mounted on the ceramic bracket 2 and whose two upper ends are exposed outside the housing 1, and the resistance band 3. Two electrode studs 4 welded to the two upper ends respectively. The cross-sectional shape of the housing 1 is circular; the material of the housing 1 is stainless steel.

[0020] The ceramic support 2 includes six circular ceramic sheets 21 horizontally spaced from top to bottom, a cylindrical ceramic block 22 arranged between every two adjacent ceramic sheets 21, fastening bolts 23, fastening nuts 24, ceramic The radial dimension of sheet 21 is larger than the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com