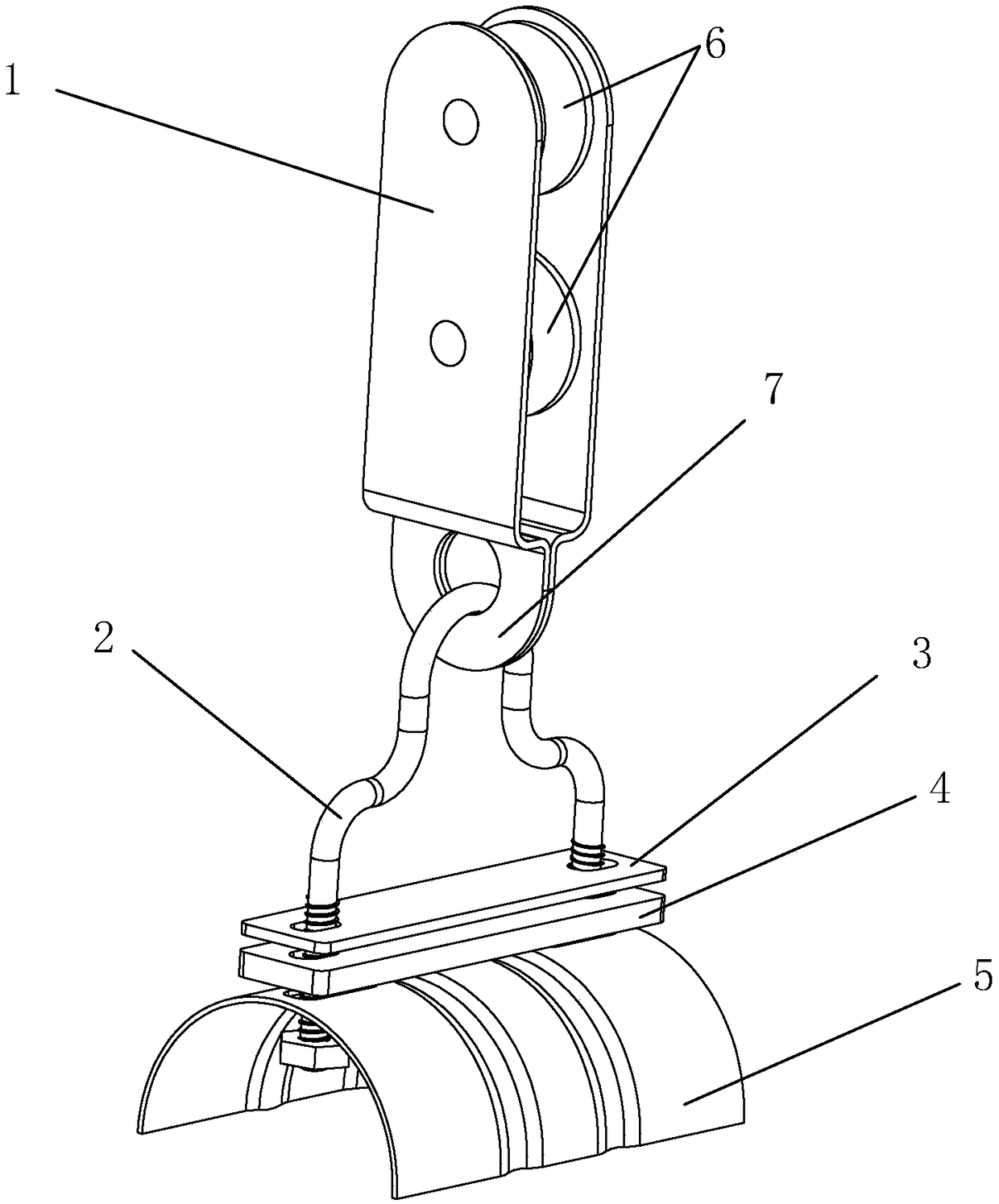

A kind of stainless steel formula specially used for crane cable block and its preparation method

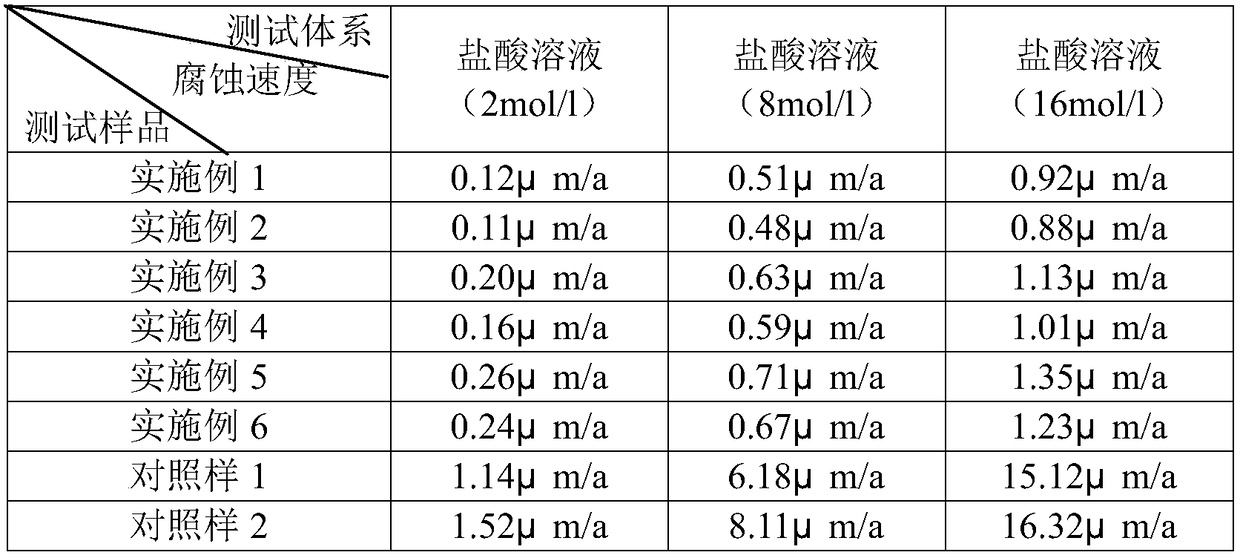

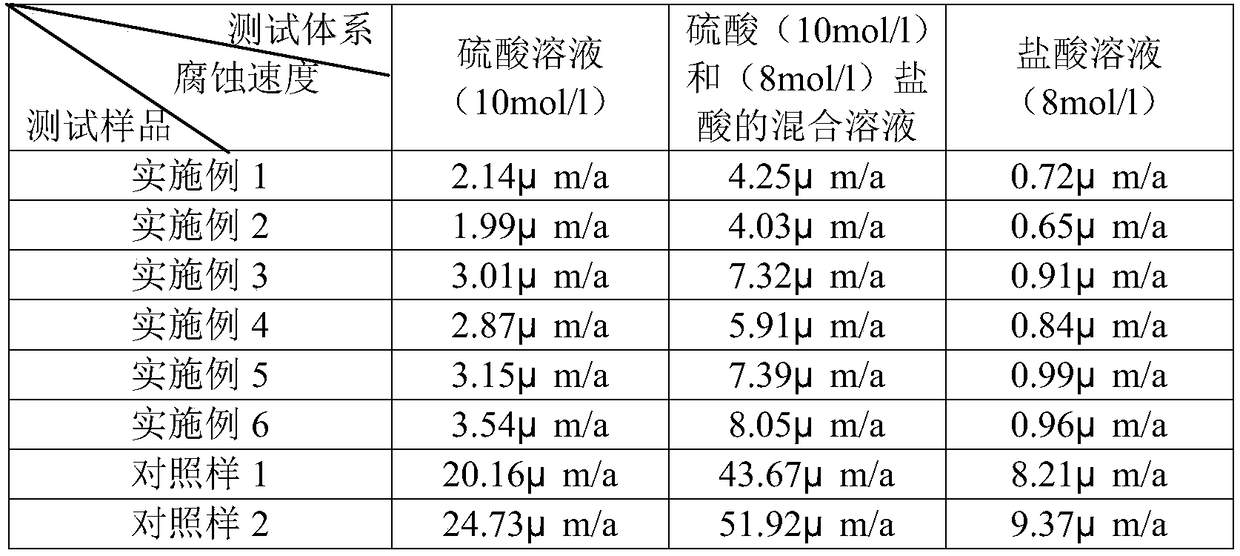

A technology for stainless steel and cranes, which is applied in the formulation of stainless steel and its preparation, can solve the problems of reducing the possibility of rusting cable blocks of cranes, rusting of cable blocks of cranes, etc., and achieves high yield strength and elongation, slow corrosion speed, and good corrosion resistance. The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: A stainless steel specially used for crane cable blocks is prepared by the following method: the following formula is used as raw material, the raw material is cold-rolled, and then solution treated. The temperature of solution treatment is 1075 ° C, and the solution time is Be 15min; Its formula is (by weight percentage):

[0058] C: 0.01%;

[0059] Si: 0.35%;

[0060] Mn: 0.03%;

[0061] S: 0.01%;

[0062] P: 0.01%;

[0063] Cr: 22.00%;

[0064] Ni: 9.00%;

[0065] Cu: 0.40%;

[0066] N: 0.02%;

[0067] Ti: 0.02%;

[0068] Fe: 68.15%.

Embodiment 2

[0069] Embodiment 2: a kind of stainless steel that is specially used in crane cable block, the difference with embodiment 1 is that its formula is (by weight percentage):

[0070] C: 0.01%;

[0071] Si: 0.40%;

[0072] Mn: 0.04%;

[0073] S: 0.01%;

[0074] P: 0.01%;

[0075] Cr: 23.00%;

[0076] Ni: 8.00%;

[0077] Cu: 0.35%;

[0078] N: 0.02%;

[0079] Ti: 0.03%;

[0080] Fe: 68.13%.

Embodiment 3

[0081] Embodiment 3: a kind of stainless steel that is specially used in crane cable block, the difference with embodiment 1 is that its formula is (by weight percentage):

[0082] C: 0.02%;

[0083] Si: 0.75%;

[0084] Mn: 0.05%;

[0085] S: 0.01%;

[0086] P: 0.02%;

[0087] Cr: 21.00%;

[0088]Ni: 9.50%;

[0089] Cu: 0.45%;

[0090] N: 0.03%;

[0091] Ti: 0.04%;

[0092] Fe: 67.59%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com