Aluminium strip with tin soldering performance and high corrosion resistance and preparation technology thereof

A preparation process and corrosion-resistant technology, which is applied in the direction of metal material coating process, liquid chemical plating, coating, etc., can solve problems such as unsatisfactory welding of aluminum strips, impossibility of assembly line production, cumbersome production process, etc., to achieve durability Improved acid-base corrosion performance, slow corrosion rate, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

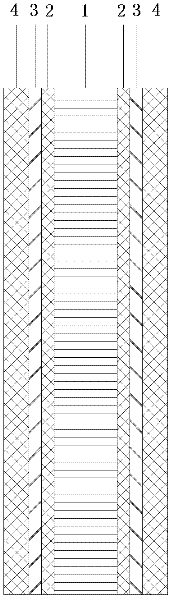

Image

Examples

Embodiment Construction

[0090] The following examples are intended to illustrate the present invention without further limiting the invention.

[0091] (Example)

[0092] A1060H16 aluminum strip with a thickness of 0.2mm is selected as the base material, and the following process is used to process it.

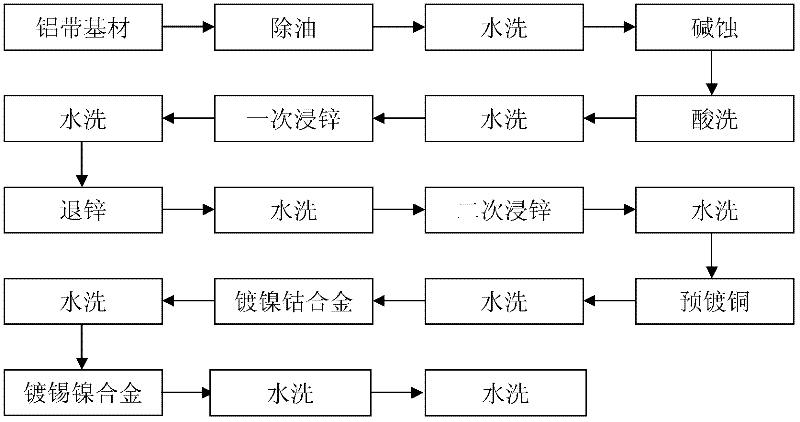

[0093] 1. Aluminum strip surface pretreatment: alkali etching, water washing, pickling, water washing, zinc dipping, water washing, pickling, water washing, secondary zinc dipping, water washing;

[0094] 2. Electrodeposition process: electroplating copper, washing; electroplating nickel-cobalt alloy, washing; electroplating nickel-tin alloy, washing; drying.

[0095] 3. Post-plating treatment: heat preservation and hydrogen removal.

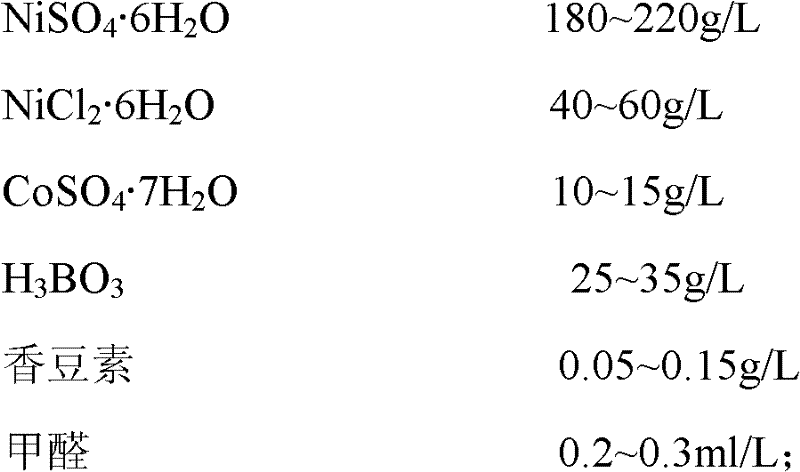

[0096] The formula and treatment process of above-mentioned various solutions and plating solutions are as follows:

[0097] The formula and treatment process of alkaline etching solution:

[0098] NaOH: 30~70g / L

[0099] Na 3 PO 4 : 20~50g / L

[0100] Na 2 CO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com