Iron-based composite material used for full-degradation cardiovascular support and preparation method thereof

An iron-based composite material, medical technology, applied in medical science, surgery, coating and other directions, can solve the problems of difficult to control the formation and uniform distribution of metal mesophase, accelerate the effect of pure iron corrosion rate, accelerate corrosion, etc., to avoid Late thrombosis, improved mechanical strength, uniform corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, preparation Fe-W / Fe 2 o 3 / FeS composite material

[0043] Pure Fe powder (99.9wt.%, particle size 100nm~100μm), W powder (99.8%, particle size 100nm~100μm), Fe 2 o 3 FeS powder (99.0%, particle size 100nm~100μm) and FeS powder (99.0%, particle size 100nm~100μm) were used as test raw materials, and were prepared according to the secondary phase X content (mass) of 2% and 5%, respectively.

[0044] After being manually mixed in a mortar, it was mixed for 5 minutes at a speed of 2000 rpm in a mixer. Put the mixed powder in a graphite mold, and in a vacuum environment, use discharge plasma sintering technology to sinter at 950 ° C under a pressure of 40 MPa, hold for 5 minutes, and then cool to room temperature to obtain iron-based composite materials: respectively Fe-2W, Fe-5W, Fe-2Fe 2 o 3 , Fe-5Fe 2 o 3 , Fe-2FeS and Fe-5FeS.

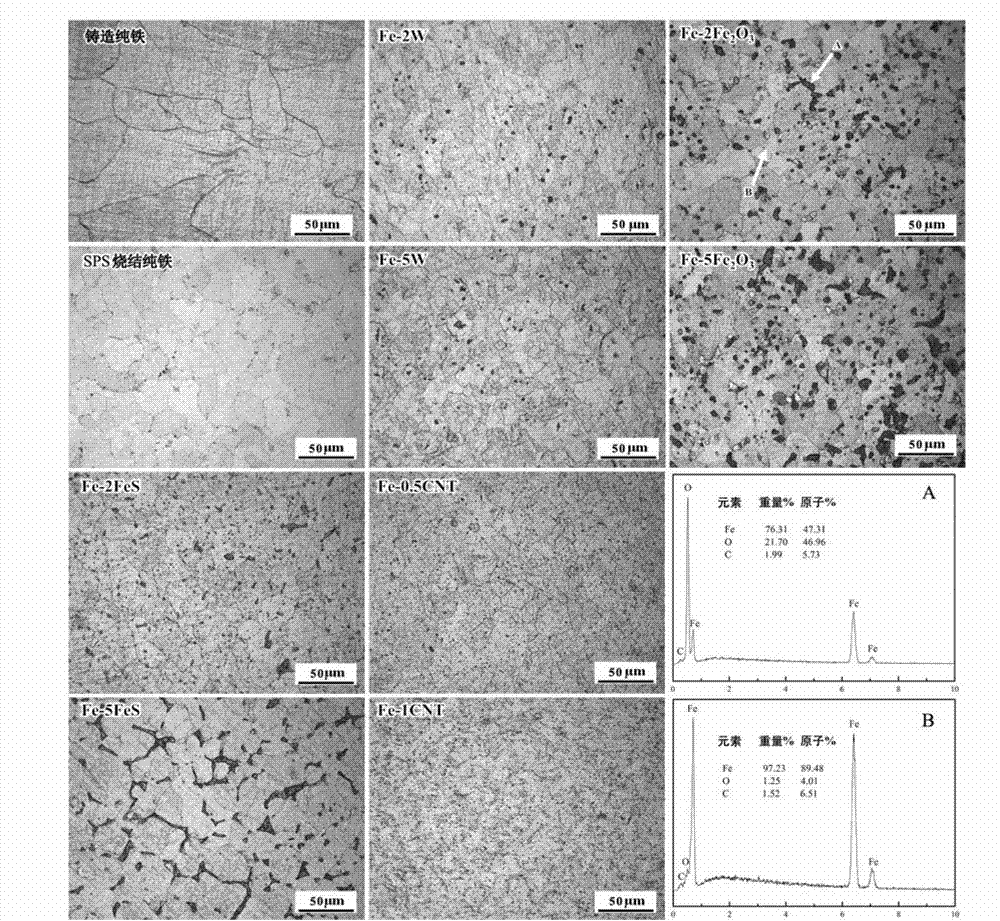

[0045] The metallographic microstructure of the iron-based composite material prepared in this example is as follows: fi...

Embodiment 2

[0046] Embodiment 2, preparation Fe-CNT composite material

[0047] Using pure Fe powder and CNT powder (diameter 10-30nm, length 1-10μm) as raw materials, according to the ratio of the added phase content of 0.5% and 1% respectively, using ethanol as a dispersant, using a stainless steel ball with a diameter of 5mm in the After ball milling and mixing for 8 hours at a rotational speed of 80 r / min, it was dried, and then sintered with the same spark plasma sintering parameters as in Example 1 to obtain a Fe-CNT composite material sample.

[0048] The metallographic microstructure of the Fe-CNT composite material prepared in this embodiment is as follows: figure 1 It can be seen from the figure that the CNTs are uniformly distributed in the iron matrix after being mixed and sintered by ball milling, and the addition of CNTs also significantly reduces the grain size of the iron matrix.

Embodiment 3

[0049] Embodiment 3, room temperature compression performance of iron-based composite material

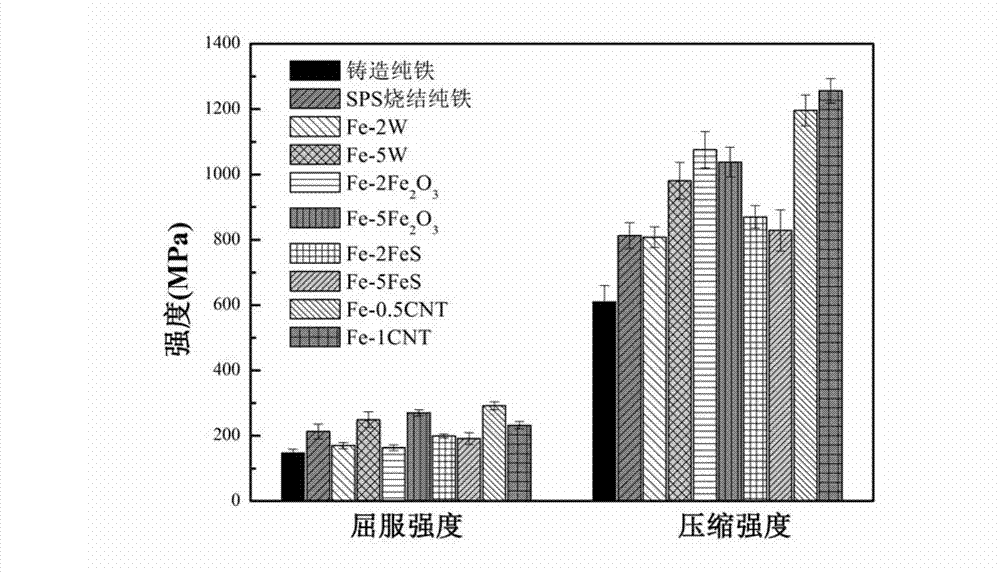

[0050] The composite materials prepared in Example 1 and Example 2 were prepared according to the compression test standard GB / T 7314-2005 to prepare compression samples for compression performance testing. The sample size was Φ2×5mm, and the compression strain rate was 2×10 -4 / s, since the material is a plastic material, the compressive strength is the stress value when the compressive strain is 40%.

[0051] The compressive mechanical properties of the iron-based composite material prepared in embodiment 1 and embodiment 2 are as follows: figure 2 As shown, cast (As-cast) pure iron and spark plasma sintered (SPS) pure iron are used for comparison.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com