Metal surface silanization treatment agent and surface silanization treatment method using the same

A technology of silanization treatment and metal surface, which is applied in the direction of devices and coatings for coating liquid on the surface, which can solve the problems of restricting development and application, and achieve the effect of easy management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

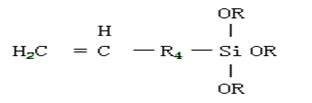

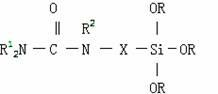

[0021] Example 1: 500g deionized water, add 80g ethanol, add 3.5g BTSE while stirring, let it stand for 2 to 5 days, the solution is transparent and clear, then add 25gA-151, 15gr-UPS while stirring, after the solution is transparent and clear, use 4g of acetic acid was used to adjust the pH, and then 1.5g of propylated zirconia was added to replenish the water to 1000g.

[0022] First, the cold-rolled steel is washed with degreasing water. The degreasing solution is best to use a formula that does not contain phosphorus to achieve phosphating-free production in the entire production line. After degreasing and washing, it can directly enter the aforementioned silanization treatment agent for treatment. A layer of coating can be obtained on the surface of the metal substrate, and then it can be washed or not washed to the next process-drying according to the process requirements, and powder spraying and other processes can be carried out after drying.

Embodiment 2

[0023] Example 2: 500g deionized water, add 100g ethanol, add 6g BTSE while stirring, let it stand for 2-5 days, the solution is transparent and clear, then add 20gA-151, 30gr-UPS while stirring, after the solution is transparent and clear, use 10g Acetic acid was used to adjust the pH, and then 1g of propylated zirconia and 3g of titanium isopropoxide were added to make up water to 1000g.

[0024]First, the aluminum alloy is degreased and washed with water. It is best to use a phosphorus-free formula for the degreasing solution to achieve non-phosphating production in the entire production line. After degreasing and washing, it can be directly treated in the aforementioned silanization treatment agent. The treatment time is 100 seconds. A layer of coating can be obtained on the surface of the substrate, and then it can be washed or not washed according to the process requirements to the next process-drying, and powder spraying and other processes can be carried out after dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com