Treating fluid and method for preparing vanadium-zirconium composite conversion coatings with self-repairing performance on aluminum alloy surfaces through same

An aluminum alloy surface and self-healing technology, which is applied in the direction of metal material coating technology, can solve the problems of complex processing technology, insufficient solution stability, and the corrosion resistance of the film layer needs to be improved, so as to achieve simple process flow, The effect of short conversion processing time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

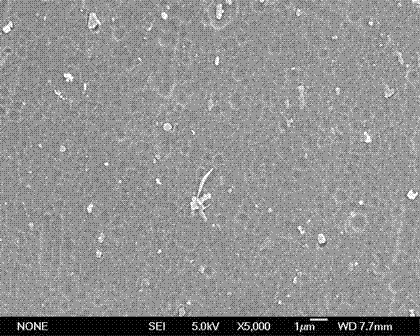

[0058] Example 1 : Preparation of self-healing vanadium-zirconium conversion coating on aluminum alloy surface

[0059] Weigh 30 g of fluozirconic acid (mass concentration: 40% to 50%) and 12.5 g of sodium metavanadate, and dissolve them in 450 g of deionized water. Take another 450g of deionized water to dissolve 2.5g of sodium fluoride, 10g of sodium nitrate, 45g of sodium borate and 20g of fluorosilicic acid, and mix the above two components evenly to obtain a light yellow vanadium-zirconium conversion treatment solution with a specific gravity of 1.11 g / cm 3 .

[0060] Dilute the above treatment solution 10 times with water to obtain the working solution, and adjust the pH value to 3.0. Prepare the A6063 aluminum alloy test piece, immerse the aluminum alloy test piece in the commercially available RS-228 acidic degreasing agent (60g / L) for 5min, after washing with deionized water, immerse the above prepared aluminum alloy surface at 30°C Treat the repairing vanadium-...

Embodiment 2

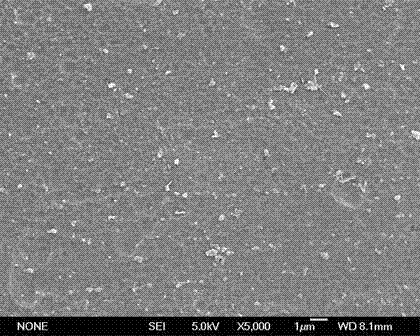

[0064] Weigh 35 g of sodium fluozirconate (mass concentration: 40% to 50%) and 15 g of ammonium metavanadate, and dissolve them in 450 g of deionized water. Take another 450g of deionized water to dissolve 3g of sodium fluoride, 15g of potassium nitrate, 40g of fluoboric acid and 20g of water-based silane DN906, and mix the above two components evenly to obtain a light yellow vanadium-zirconium conversion treatment solution with a specific gravity of 1.14 g / cm 3 .

[0065] Dilute the above treatment solution 15 times with water to obtain the working solution, and adjust the pH value to 2.5. Prepare the A6063 aluminum alloy test piece, immerse the aluminum alloy test piece in the commercially available RS-228 acidic degreasing agent (60g / L) for 8 minutes, wash it with water, and immerse it in the prepared aluminum alloy surface self-healing property at a temperature of 35°C Treatment of the vanadium-zirconium conversion film in the working solution for 6 minutes, the test piec...

Embodiment 3

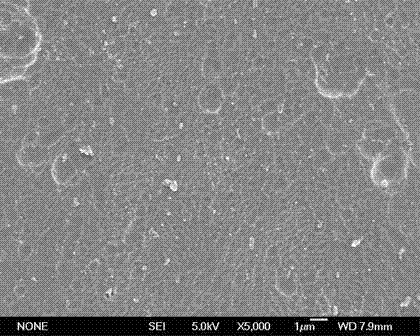

[0069] Weigh 30 g of potassium fluozirconate (mass concentration: 40% to 50%), and 10 g of potassium metavanadate, and dissolve them in 450 g of deionized water. Take another 450g of deionized water to dissolve 2g of sodium fluoride, 12g of calcium nitrate, 40g of citric acid and 20g of hydrogen peroxide (30% mass concentration), and mix the above two components evenly to obtain a light yellow vanadium-zirconium conversion treatment solution with a specific gravity of 1.12 g / cm 3 .

[0070] Dilute the above treatment solution 12 times with water to obtain the working solution, and adjust the pH value to 3.5. Prepare the A6063 aluminum alloy test piece, immerse it in the commercially available HOS-513 environmental protection weak alkaline degreasing agent (70g / L) for 5 minutes, wash it with water and immerse it in 15% nitric acid solution for 20 seconds, wash it with tap water and deionized water respectively, and then immerse it in The above-mentioned prepared aluminum all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com