Micro-arc oxidation treatment method of heat-resistant cast rare earth magnesium alloy

A technology of micro-arc oxidation and treatment method, which is applied in the direction of anodic oxidation, etc., to achieve the effect of simple equipment, excellent corrosion resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

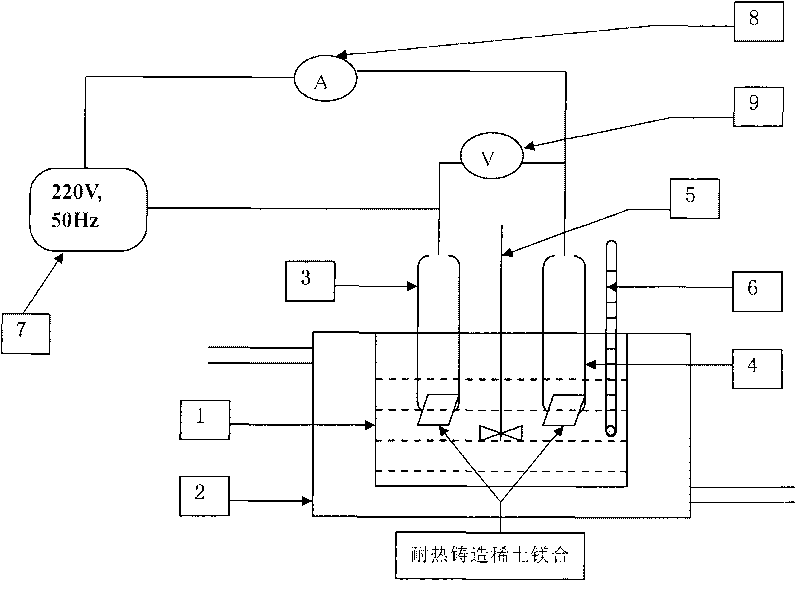

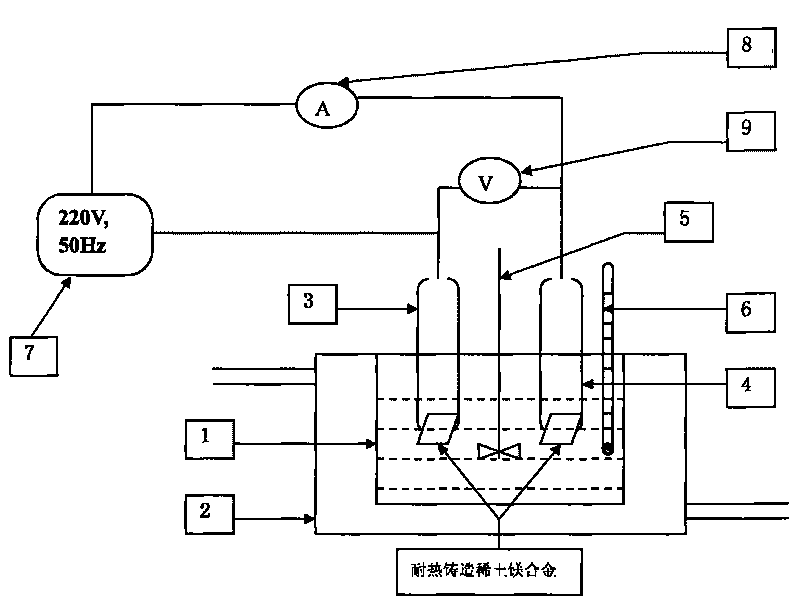

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of electrolyte solution

[0031] Dissolve sodium silicate with distilled water, and then pour it into the electrolytic tank to make the concentration 5g / L; auxiliary agents, additives and pH regulators also need to be dissolved in distilled water and then poured into the electrolytic tank, the concentration of sodium fluoride is 8g / L, the concentration of glycerin is 10mL / L, and the concentration of potassium hydroxide is 8g / L.

[0032] (2) Pretreatment of heat-resistant cast rare earth magnesium alloy

[0033] The size of the alloy sample used is: 25mm×17mm×8mm, and the sample is passed through 300 # and 600 # Grinding and deburring with water abrasive paper;

[0034] Prepare a sodium hydroxide degreaser solution with a concentration of 100g / L. Put the sample into this solution, soak it at 60°C for 20 minutes, take it out, rinse it with clean water, and then rinse it with distilled water; or, when the surface of the sample is more oily, boil it in 90...

Embodiment 2

[0040] (1) Preparation of electrolyte solution

[0041] Dissolve sodium aluminate with distilled water and pour it into the electrolytic cell to make the concentration 8g / L; then make the concentration of sodium fluoride 4g / L, the concentration of glycerin 10mL / L, and the concentration of potassium hydroxide 6g / L and dissolve it in distilled water Then pour into the electrolytic tank and stir evenly.

[0042] (2) The pretreatment of the magnesium alloy sample is carried out according to (2) in Example 1.

[0043] (3) Sample MAO processing

[0044] Put the sample to be treated in the electrolyte, and use the voltage regulator to quickly adjust the arcing voltage to 200V. After the spark discharge occurs on the surface of the sample, the current value gradually drops to the range of 0.4 amperes with the formation of the ceramic film on the surface of the sample. Within this range, keep the current value unchanged. After staying for 3 seconds, increase the voltage to make the c...

Embodiment 3

[0047] (1) Preparation of electrolyte solution

[0048] Dissolve sodium phosphate with distilled water and pour it into the electrolytic cell to make the concentration 6.5g / L; dissolve sodium fluoride with distilled water to a concentration of 4g / L, glycerin to a concentration of 10mL / L, and potassium hydroxide to a concentration of 4g / L Pour into the electrolytic tank, stir evenly, and set aside.

[0049] (2) Pretreatment of magnesium alloy samples

[0050] Carry out by (2) in embodiment 1.

[0051] (3) MAO treatment

[0052] Put the sample to be processed in the electrolyte (1), and quickly adjust the arcing voltage to 200V with a voltage regulator. After spark discharge occurs on the surface of the sample, the current value gradually increases with the formation of the ceramic film on the surface of the sample. Drop to the range of 0.5 ampere, keep the current value in this range, after staying for 3 seconds, increase the voltage to make the current rise gradually at an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com