Metal surface vitrification agent and application method thereof

A metal surface and vitrifying agent technology, which is applied in the direction of metal material coating technology, can solve environmental pollution and other problems, and achieve the effects of enhancing corrosion resistance, improving adhesion, and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

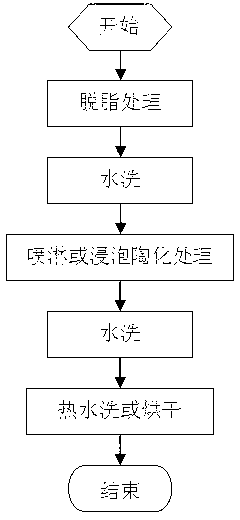

Image

Examples

Embodiment Construction

[0019] The metal surface vitrifying agent of the present invention contains 2.0-38.0% of zirconium-titanium salt, 0.1-8.0% of silane, 0.5-18.0% of buffering agent, 0.01-5.00% of film-forming aid, 0.1-6.1% of rust inhibitor, and 0.2% of complexing agent. ~7.0%, the appearance is clear and transparent liquid, and no suspended matter; PH value is 1~2; specific gravity is 1.05±0.02g / cm 3 Wherein, the zirconium-titanium salt includes zirconium boride, fluorozirconic acid, titanyl sulfate or titanium fluorozirconate, the silane includes low molecular weight water-soluble silane, the buffering agent includes weak acid or weakly basic amines, and the film-forming aid includes molybdic acid Or molybdate, antirust agent comprises boric acid or borate, and complexing agent comprises citric acid, EDTA or acetic acid; Said percentage is percentage by weight. The low-molecular-weight water-soluble silane includes tetraethoxysilane, dimethyldiethoxysilane or vinyltriethoxysilane; the buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com