Phospahte coated stainless steel wire for cold heading and self-drilling screw using the stainless steel wire

A technology of stainless steel wire and phosphate coating, applied in the direction of screws, nails, phosphating, etc., can solve the problem of not revealing the method of stainless steel wire and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

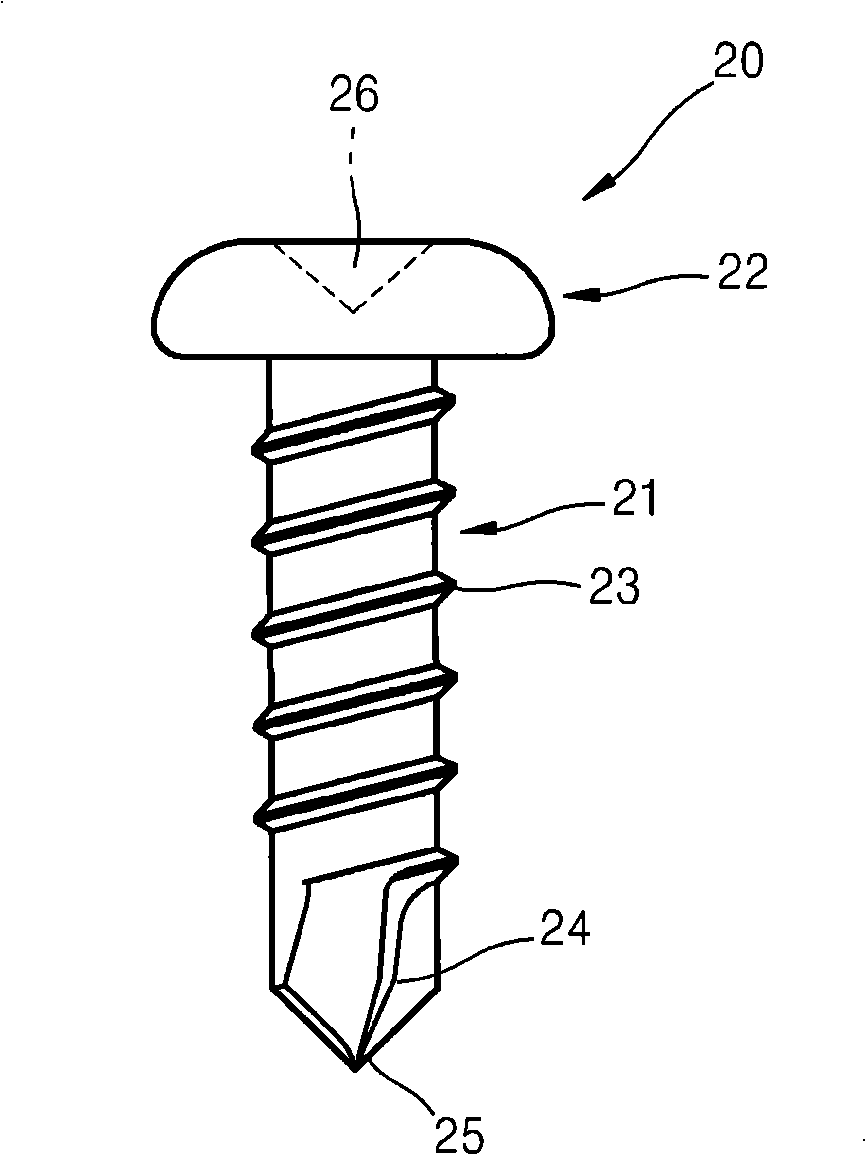

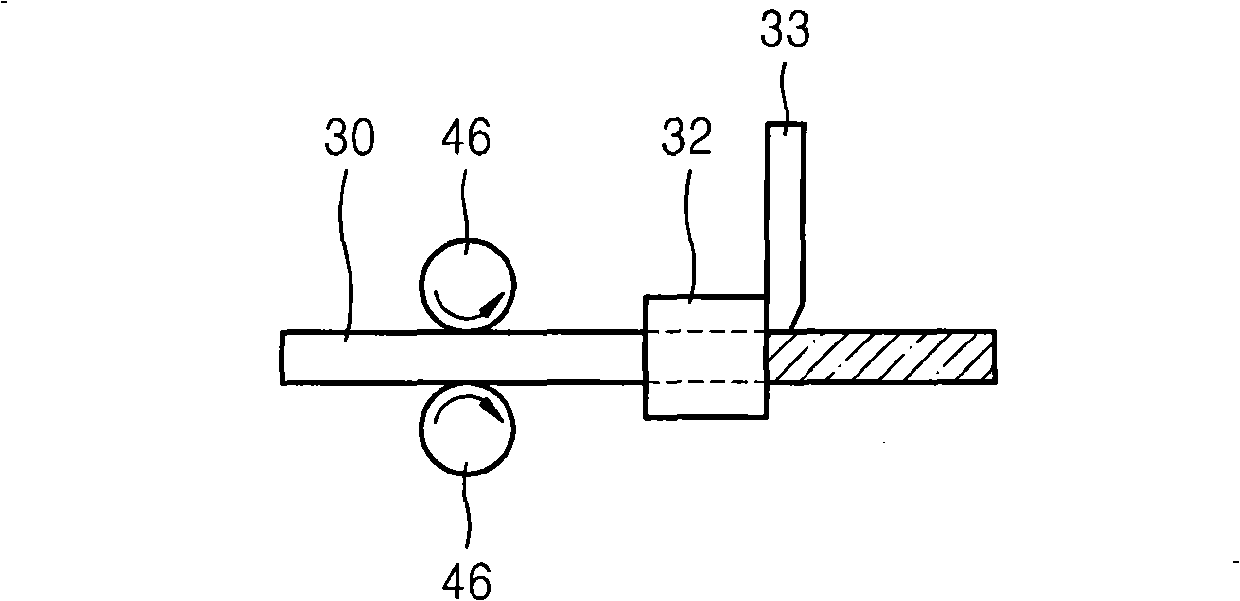

[0028] The present invention will now be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown.

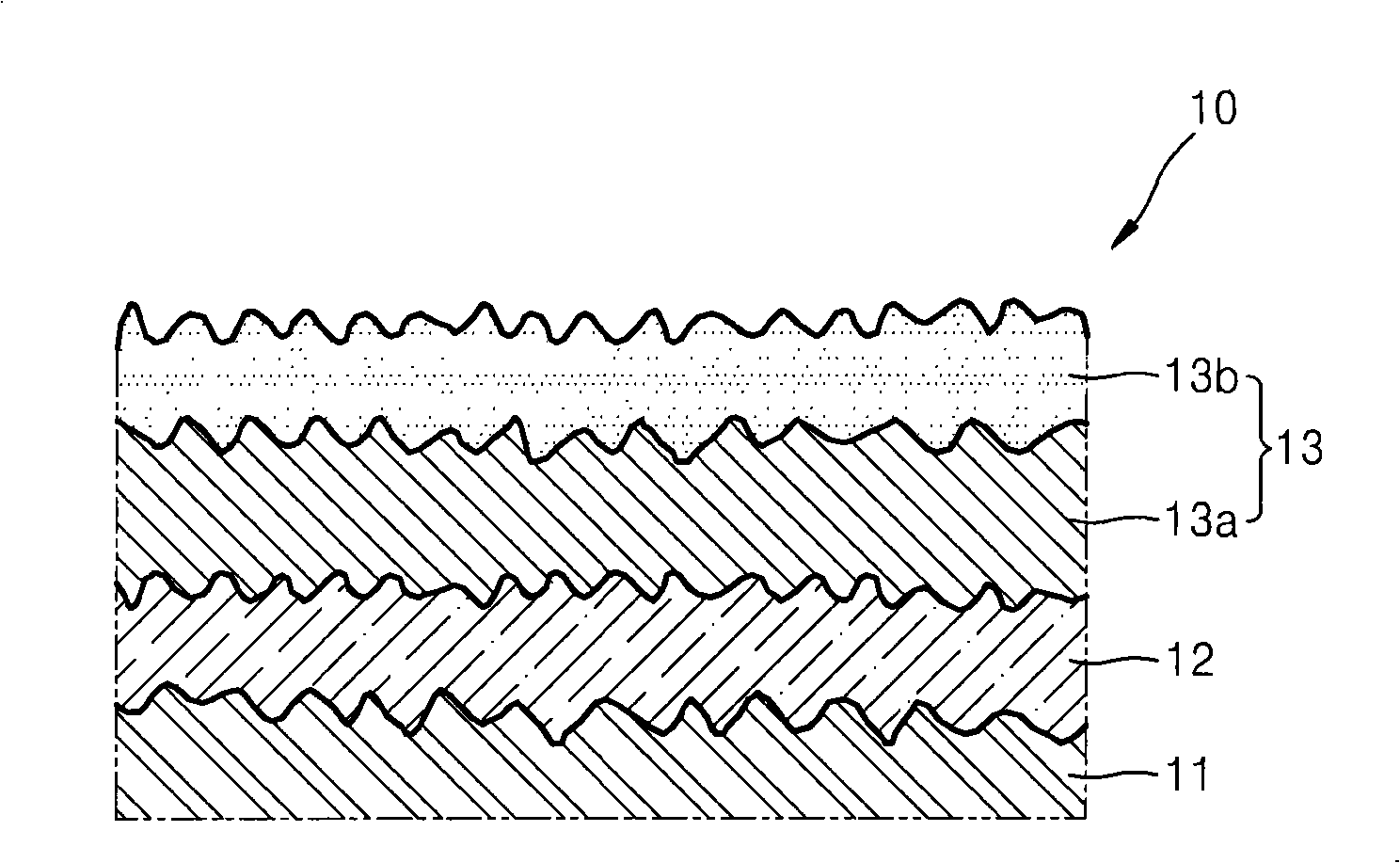

[0029] A phosphate-coated stainless steel wire for cold heading according to one embodiment of the present invention will now be described.

[0030] Bright annealed wire (bright annealed wire) is prepared as stainless steel wire, which contains by weight less than 0.15% carbon (C), less than 1.0% silicon (Si), less than 1.0% manganese (Mn), 11.50-13.50% Chromium (Cr), less than 0.040% phosphorus (P) and less than 0.030% sulfur. Stainless steel wire can have less than 550N / mm 2 The tensile strength (tensile strength).

[0031] The prepared stainless steel wire was electrolytically pickled using a sulfuric acid solution as an electrolytic solution to completely remove scale on the surface. Next, the stainless steel wire is cathodically polarized in a plating tank using a phosphoric acid solution as an electroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com