Preparation method of honeycomb carrier catalyst for molecular sieve denitration

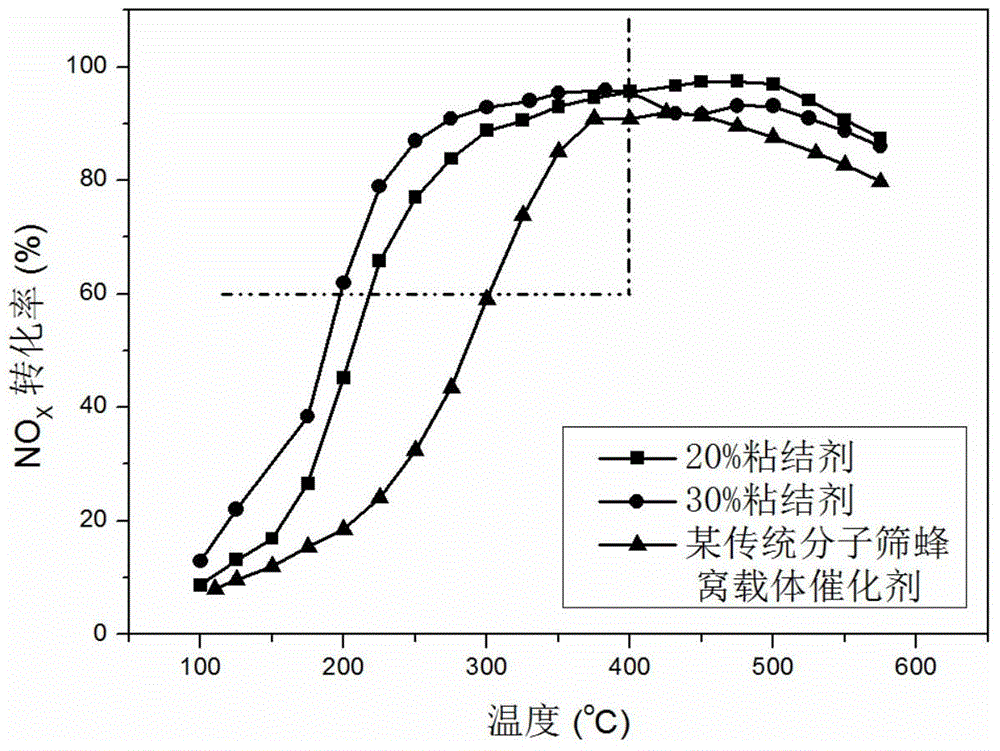

A technology of honeycomb carrier and out-of-stock catalyst, which is applied in molecular sieve catalysts, separation methods, chemical instruments and methods, etc., which can solve problems such as unfavorable catalytic reactions, active powder shedding, and inhibition of catalytic activity of catalysts, so as to improve catalytic activity and reduce mechanical vibration , good denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: the Cu / ZSM-5 catalyst that adopts ion exchange method to prepare copper content is 1.5wt%: concrete method is: take by weighing 24.16g Cu (NO 3 ) 2 ·3H 2 O, dissolved in 500mL deionized water, stirred evenly to obtain 0.2mol L -1 Copper nitrate solution; Weigh 10g molecular sieves, gradually add into the copper nitrate solution, stir for 1h; then filter with suction, separate the solid from the liquid and clean the solid sample, then put it in an oven at 110°C to dry overnight, and bake in an air atmosphere at 400°C After 2 hours, the Cu / ZSM-5 catalyst was obtained, cooled naturally to room temperature, and then ground into small particles below 90 mesh for future use.

[0021] Step 2: Carrier pretreatment: Soak the cordierite honeycomb ceramic carrier in acid-base and organic solvent conditions for 24 hours, wash it with deionized water, and dry it in an oven at 110°C.

[0022] Step 3: Weigh 20g of Cu / ZSM-5, grind it thoroughly and dissolve it in 23.3g of et...

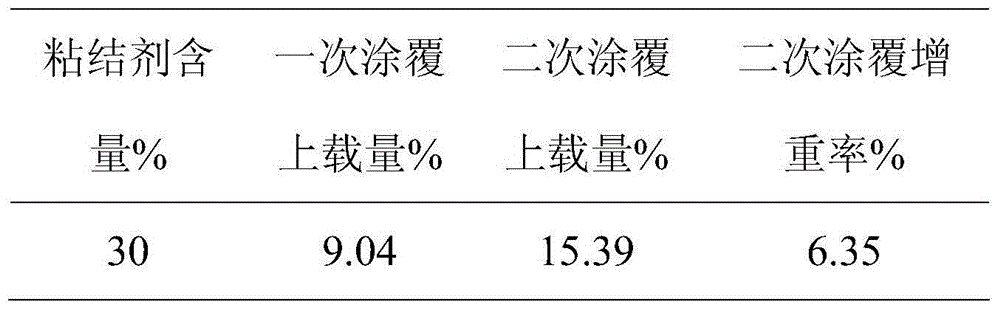

Embodiment 2

[0026] Step 1: the Cu / ZSM-5 catalyst that adopts ion exchange method to prepare copper content is 1.5wt%: concrete method is: take by weighing 24.16g Cu (NO 3 ) 2 ·3H 2 O, dissolved in 500mL deionized water, stirred evenly to obtain 0.2mol L -1 Copper nitrate solution; Weigh 10g molecular sieves, gradually add into the copper nitrate solution, stir for 1h; then filter with suction, separate the solid from the liquid and clean the solid sample, then put it in an oven at 110°C to dry overnight, and bake in an air atmosphere at 400°C After 2 hours, the Cu / ZSM-5 catalyst was obtained, cooled naturally to room temperature, and then ground into small particles below 90 mesh for future use.

[0027] Step 2: Carrier pretreatment: Soak the cordierite honeycomb ceramic carrier in acid-base and organic solvent conditions for 24 hours, wash it with deionized water, and dry it in an oven at 110°C.

[0028] Step 3: Weigh 20g of Cu / ZSM-5, grind it thoroughly and dissolve it in 23.3g of et...

Embodiment 3

[0033] Step 1: the Cu / ZSM-5 catalyst that adopts ion exchange method to prepare copper content is 2.5wt%: concrete method is: take by weighing 36.24g Cu (NO 3 ) 2 ·3H 2 O, dissolved in 500mL deionized water, stirred evenly to obtain 0.3mol L -1 Copper nitrate solution; weigh 10g of molecular sieves, gradually add it to the copper nitrate solution, stir for 2 hours; then filter with suction, separate the solid from the liquid and clean the solid sample, then put it in an oven at 120°C to dry overnight, and bake it in an air atmosphere at 400°C for 4 hours , to obtain a Cu / ZSM-5 catalyst, which was cooled naturally to room temperature and ground into small particles below 90 mesh for later use.

[0034]Step 2: Carrier pretreatment: Soak the cordierite honeycomb ceramic carrier in acid-base and organic solvent conditions for 24 hours, wash it with deionized water, and dry it in an oven at 110°C.

[0035] Step 3: Weigh 20g of Cu / ZSM-5, dissolve it in 23.3g of ethylene glycol af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com