Current collector, preparation method of current collector and lithium ion battery comprising current collector

A current collector and positive electrode current collector technology, which is applied in the direction of battery electrodes, secondary batteries, electrode carriers/collectors, etc., can solve problems such as not significantly improving the safety performance of lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also relates to a method for preparing the current collector, comprising the following steps:

[0040] Prepare an aqueous solution containing a thickener, a conductive agent and a binder, the solid content of the thickener, a conductive agent and a binder is 1 to 10%, preferably 5 to 10%; and then coated on the positive current collector and / or At least one side of the negative electrode current collector, preferably on both sides of the current collector, and finally dried at 85°C to obtain a current collector with a conductive paste coating;

[0041] At least one of the PEDOT:PSS polymers shown in formula I, formula II or formula III is dissolved in an aqueous solution with a solid content of 1 to 10%, preferably 5 to 10%; On at least one side of the positive electrode current collector and / or the negative electrode current collector, after drying, a double-coated current collector is obtained. The thickener can be selected from CMC, the conduct...

Embodiment 1

[0048] (1) Preparation of PEDOT:PSS coated current collector

[0049] First of all, take CMC, Super-P (product name: Super-P conductive carbon black, manufacturer: Swiss Temigo), SBR according to the weight ratio of 10:60:30 to configure the slurry, the solvent is deionized water, The solid content is 10%, evenly coated on both sides on 10μ copper foil (negative electrode current collector raw material) or 12μ aluminum foil (positive electrode current collector raw material), the single-layer coating thickness is 1μm, and dried to obtain a conductive paste coating the current collector;

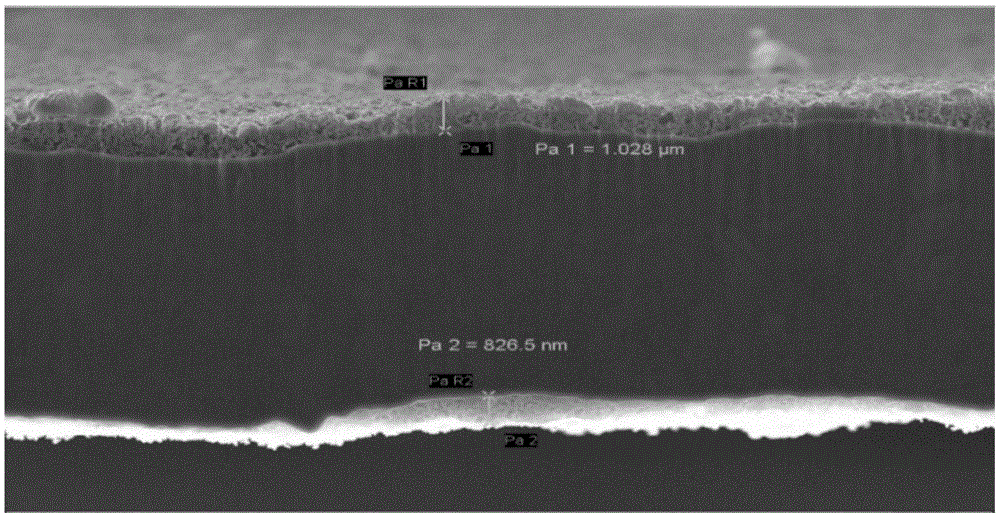

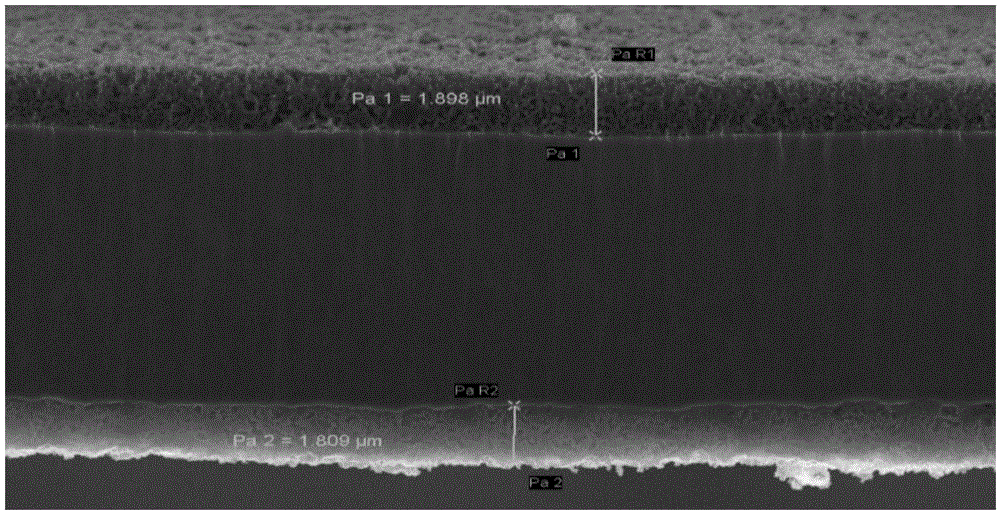

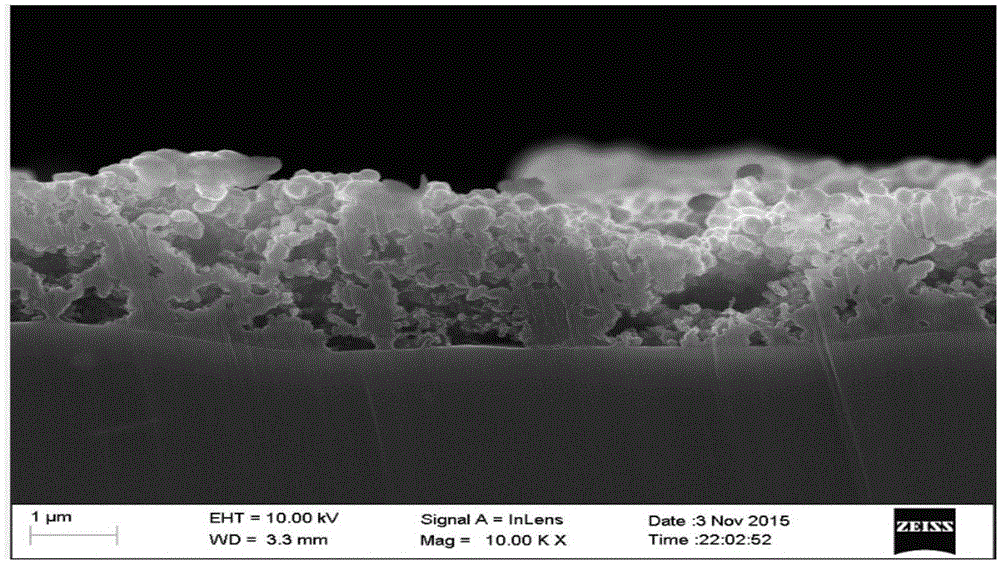

[0050] Secondly, the polymer PEDOT:PSS (Formula 1) was dissolved in water with a solid content of 10%, and double-sided uniform coating was applied to the positive or negative electrode current collector that had been coated with a conductive agent. The thickness of the single-layer coating was 1 μm. Dry to obtain a double-coated current collector. The SEM images are as follows figure 2 a...

Embodiment 2~29

[0060] Examples 2-29 Prepare double-coated current collectors and lithium-ion batteries in the same manner as in Example 1, and the conductive paste coating is the same; the difference is: the structural formula of PEDOT:PSS polymer is different, and / or PEDOT : PSS coating thickness is different. The details are shown in Table 1.

[0061] Table 1: Properties of positive and negative electrode collectors in Examples 2-21

[0062]

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single side thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com