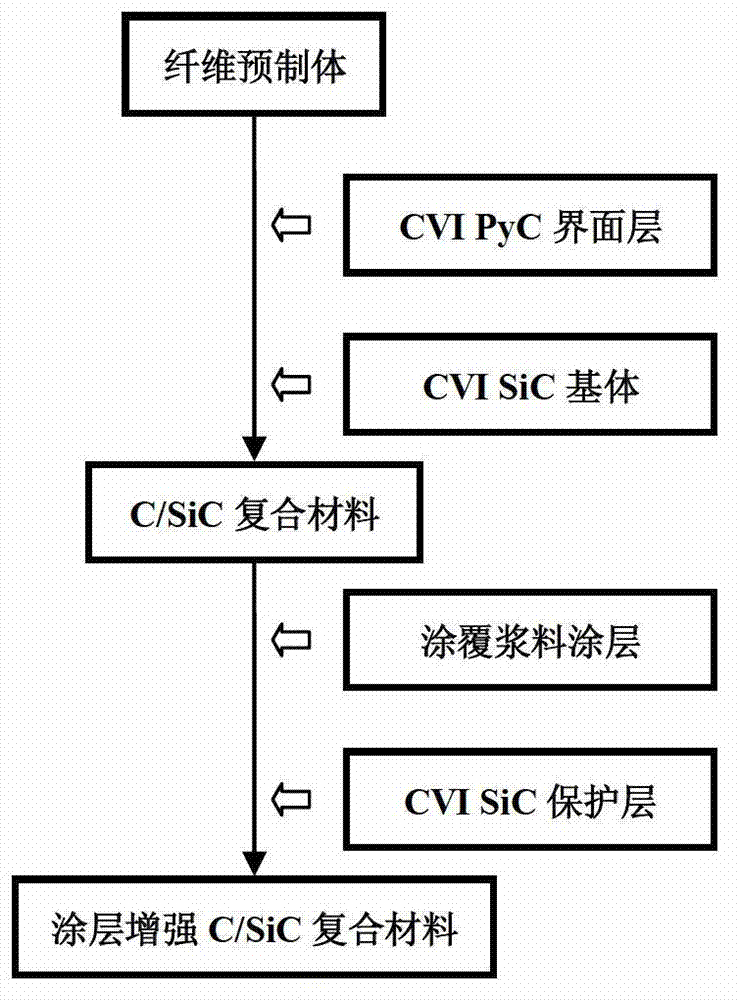

Method for preparing coating reinforced C/SiC composite material

A composite material and coating technology, applied in the field of composite material preparation, can solve the problems of reducing the porosity of the composite material and reducing the damping performance of the material, and achieve the effects of improving the strength and toughness, improving the compactness and alleviating the modulus mismatch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1, preparing SiC whisker slurry, the specific process is:

[0032] (1) Use SiC whiskers with an aspect ratio of 8-11, use 20% alcohol as a solution, ultrasonicate for 30 minutes, and dry;

[0033] (2) The volume fraction of SiC whiskers is 30%, ethanol is used as solvent, triethyl phosphate is used as dispersant, and ball milling is carried out for 5 hours;

[0034] (3) in above-mentioned slurry, add PVB binding agent, glycerol plasticizer, ball mill 5h;

[0035] (4) Vacuum degassing for 20 minutes to prepare a stable SiC whisker slurry.

[0036] Step 2, prepare SiC whisker coating reinforced C / SiC composite material. The specific process is:

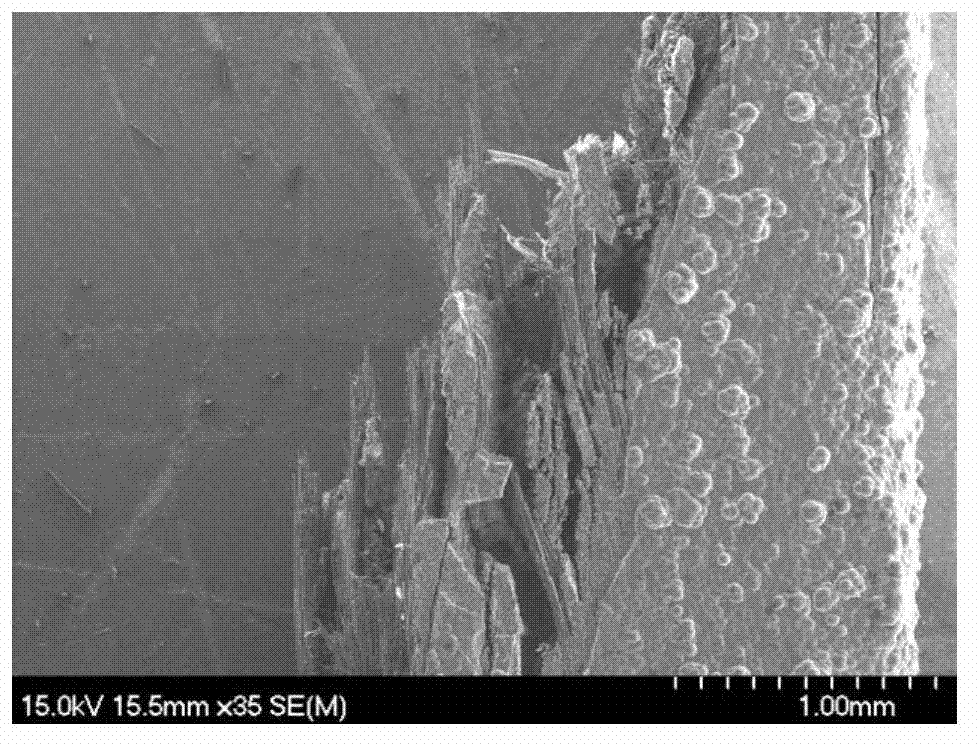

[0037] (1) A two-dimensional preform is prepared by laminating 1K plain weave carbon cloth, and the volume percentage of fibers is 40%;

[0038] (2) With propylene as the source material and argon as the dilution gas, the PyC interface was deposited by chemical vapor infiltration, the deposition temperature was 900 °C, a...

Embodiment 2

[0045] Step 1, prepare SiC particle slurry. The specific process is:

[0046] (1) SiC particles with a diameter of 0.5 μm are used as a solution with a volume fraction of 20% alcohol, ultrasonicated for 30 minutes, and dried;

[0047] (2) The volume fraction of SiC particles is 30%, ethanol is used as solvent, triethyl phosphate is used as dispersant, and ball milling is performed for 5 hours;

[0048] (3) in above-mentioned slurry, add PVB binding agent, glycerol plasticizer, ball mill 5h;

[0049] (4) Vacuum degassing for 20 minutes to prepare a stable SiC particle slurry.

[0050] Step 2, preparing SiC particle coating reinforced C / SiC composite material. The specific process is:

[0051](1) A two-dimensional preform is prepared by laminating 1K plain weave carbon cloth, and the volume percentage of fibers is 40%;

[0052] (2) With propylene as the source material and argon as the dilution gas, the PyC interface was deposited by chemical vapor infiltration, the deposit...

Embodiment 3

[0058] Embodiment 3: step 1, preparing (SiC whiskers+SiC particles) slurry. The specific process is:

[0059] (1) Use SiC whiskers with an aspect ratio of 8-11 and SiC particles with a diameter of 0.5 μm, and a mixed powder with a mass ratio of 2:1, use 20% alcohol as a solution, ultrasonic for 30 minutes, and dry ;

[0060] (2) The volume fraction of the powder is 30%, ethanol is the solvent, triethyl phosphate is the dispersant, and ball milled for 5 hours;

[0061] (3) in above-mentioned slurry, add PVB binding agent, glycerol plasticizer, ball mill 5h;

[0062] (4) Vacuum degassing for 20 minutes to prepare a stable (SiC whisker + SiC particles) slurry.

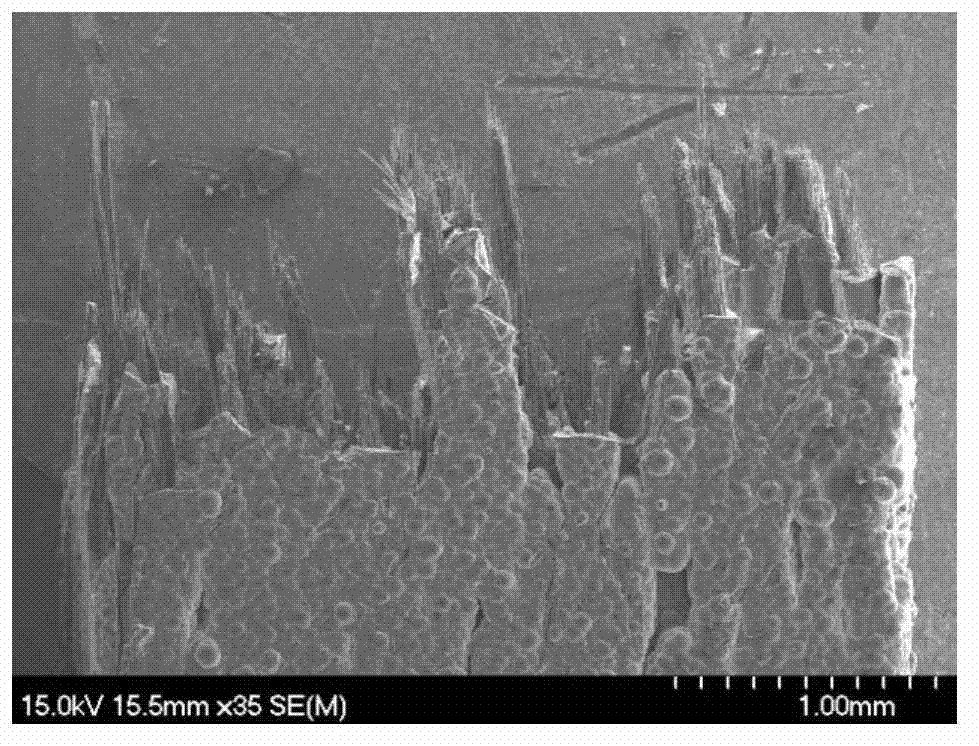

[0063] Step 2, preparing (SiC whisker + SiC particle) coating reinforced C / SiC composite material. The specific process is:

[0064] (1) A two-dimensional preform is prepared by laminating 1K plain weave carbon cloth, and the volume percentage of fibers is 40%;

[0065] (2) With propylene as the source material and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com