Preparation method of catalyst for catalytic combustion of organic exhaust gas

A catalytic combustion and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve complex problems such as easy cracking of coatings, peeling off, and large differences in hardness, etc., to achieve improvement Dispersion performance, avoiding the decline of mechanical strength, and the effect of not falling off easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Pretreatment of the honeycomb ceramic substrate: at 20°C, put the honeycomb ceramic substrate into a nitric acid solution with a concentration of 5% by mass, ultrasonically treat the honeycomb ceramic substrate for 80 minutes, and dry it at 100°C for 12 hours after pretreatment. Ultrasonic radiation power is 2 W / ml pretreatment liquid.

[0040] Slurry preparation: 50 grams of γ-alumina with a particle size of 50 nm, 10 grams of cerium-zirconium oxide with a particle size of 80 nm (Ce / Zr ratio of 1:20) and 20 grams of aluminum sol with a particle size of 80 nm were added to 100 mL of distilled water stirred at high speed After stirring evenly, add 5 grams of triethylenediamine and continue stirring for 30 minutes; add nitric acid to adjust the pH value of the slurry to 4, and continue stirring for 60 minutes to obtain the slurry.

[0041] Coating loading: immerse the pretreated cordierite honeycomb ceramic carrier in the slurry prepared above, take it out, blow off the r...

Embodiment 2

[0045] Pretreatment of the honeycomb ceramic substrate: at 80°C, put the honeycomb ceramic substrate into an oxalic acid solution with a mass percent concentration of 50%, ultrasonically treat the honeycomb ceramic substrate for 10 minutes, and dry it at 120°C for 6 hours after pretreatment. Ultrasonic radiation power is 10 W / ml pretreatment liquid.

[0046] Slurry preparation: 30 grams of γ-alumina with a particle size of 20 nm, 5 grams of cerium-zirconium oxide with a particle size of 50 nm (Ce / Zr ratio of 1:10) and 15 grams of aluminum sol with a particle size of 80 nm were added to 100 mL of distilled water stirred at high speed After stirring evenly, add 10 grams of isopropylamine and continue stirring for 30 minutes; add nitric acid to adjust the pH value of the slurry to 3.5, and continue stirring for 60 minutes to obtain the slurry.

[0047] Coating loading: immerse the pretreated cordierite honeycomb ceramic carrier in the slurry prepared above, take it out, blow off ...

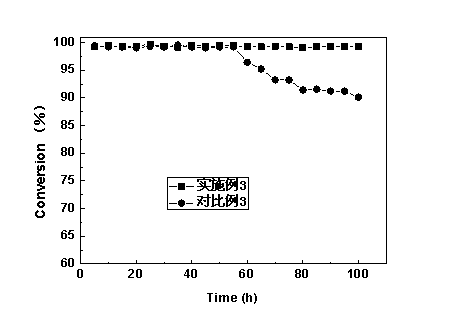

Embodiment 3

[0051] Pretreatment of the honeycomb ceramic substrate: at 50°C, put the honeycomb ceramic substrate into a hydrochloric acid solution with a concentration of 15% by mass, ultrasonically treat the honeycomb ceramic substrate for 100 minutes, and dry it at 110°C for 12 hours after pretreatment. Ultrasonic radiation power is 0.1 W / ml pretreatment liquid.

[0052] Slurry preparation: 25 grams of γ-alumina with a particle size of 100 nm, 30 grams of cerium-zirconium oxide with a particle size of 120 nm (Ce / Zr ratio of 1:1) and 25 grams of aluminum sol with a particle size of 80 nm were added to 100 mL Distilled water with high-speed stirring; after stirring evenly, add 8 grams of isopropylamine and continue stirring for 30 minutes; add nitric acid to adjust the pH value of the slurry to 3.5, and continue stirring for 60 minutes to obtain the slurry.

[0053] Coating loading: immerse the pretreated cordierite honeycomb ceramic carrier in the slurry prepared above, take it out, blow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com