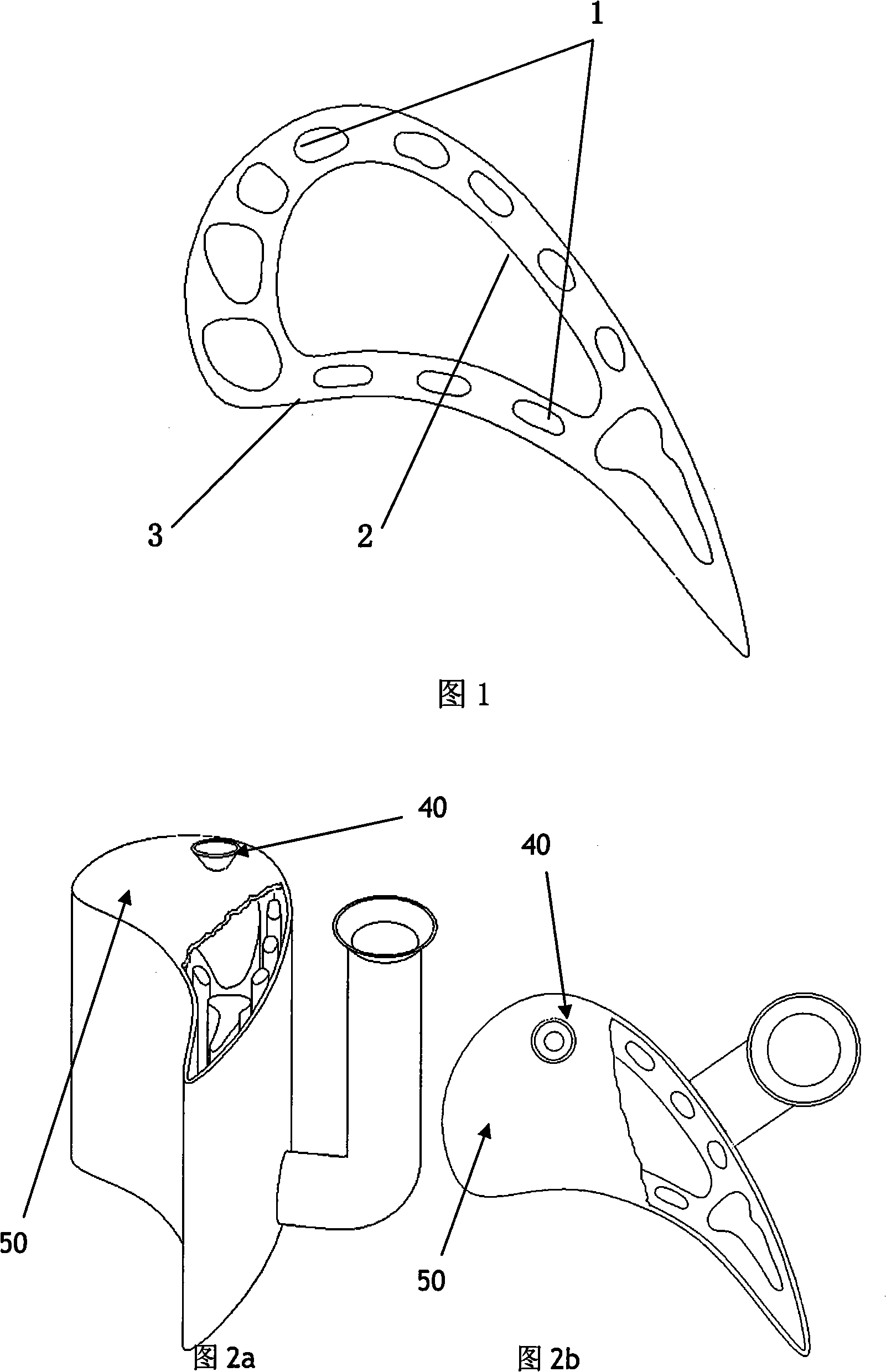

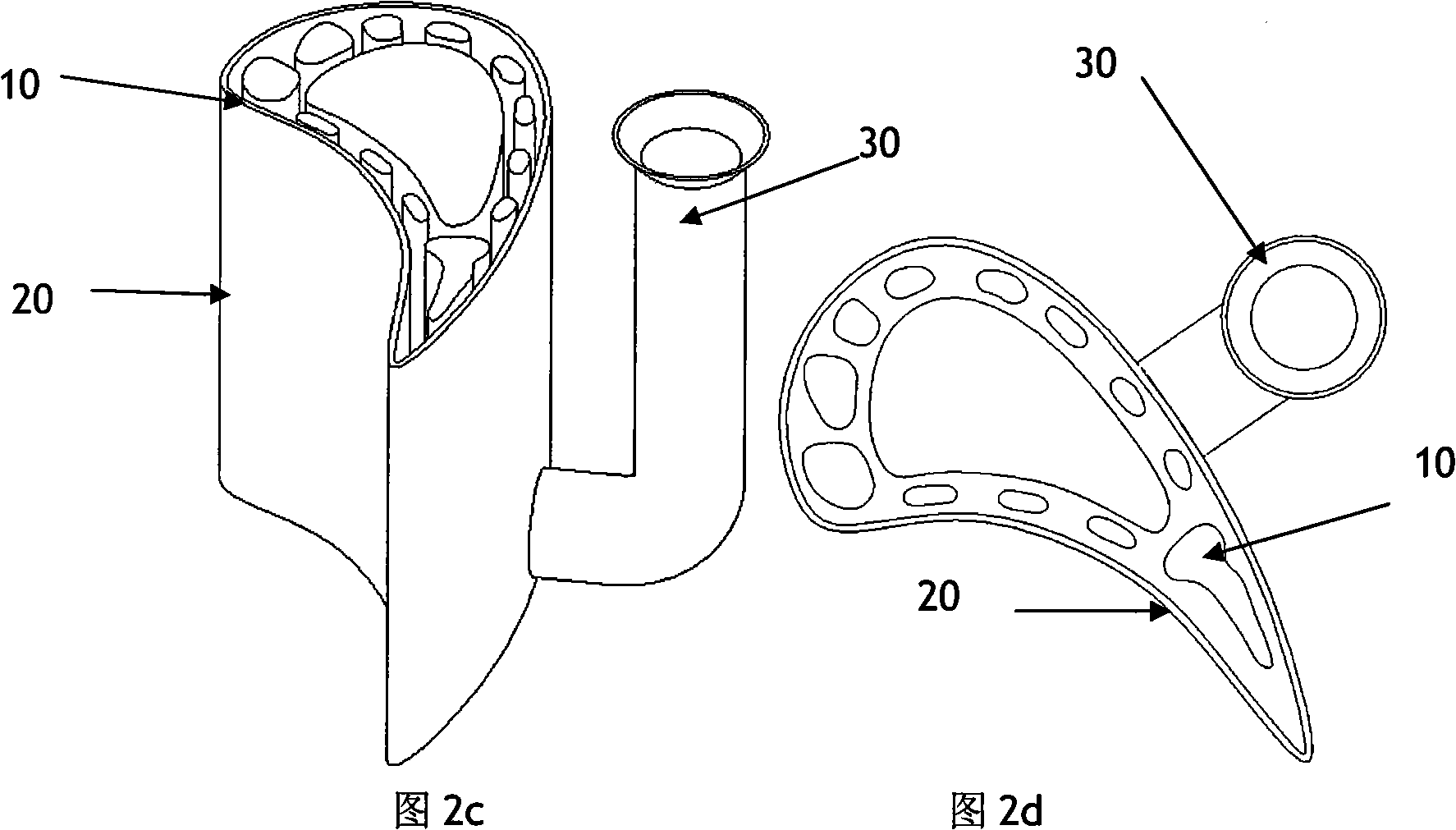

Direct light-curing fabrication method of hollow blade ceramic cast

A technology of ceramic molds and hollow blades, which is applied in the field of precision casting, can solve the problems of increasing the production cost of parts, positioning errors, and large costs, and achieve the effects of ensuring mutual position accuracy, reducing manufacturing costs, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 800g of silica sol, 200g of glycerin, mix them to dissolve each other, add 240g of acrylamide and 10g of N-N'methylenebisacrylamide to the above solution, and dissolve them completely to obtain a transparent premix.

[0035] In the above premix, add 8 μm silicon oxide powder 2120g and 1.8 μm silicon oxide powder 530g (mass fraction is 70%), dispersant sodium polyacrylate 8ml (0.3% of ceramic powder mass), after adding the above powder each time Ball milled for 3 hours, finally added 8ml (0.8% of the premixed liquid quality) photoinitiator 1173 (2-hydroxyl-methylphenylpropane-1-one), ball milled for 1 hour, the photoinitiator was fully mixed with the slurry, A uniformly dispersed ceramic slurry is obtained.

[0036] Add the ceramic slurry into the resin tank of the light-curing molding machine (SPS450B, manufactured by Shaanxi Hengtong Intelligent Machine Co., Ltd.); use the 3D solid modeling software PRO / E to process the 3D model of the blade to obtain the 3D soli...

Embodiment 2

[0040] Weigh 875g of silica sol, add 356.25g of acrylamide and 18.75g of N-N'methylenebisacrylamide into the silica sol, and dissolve them completely to obtain a transparent premix.

[0041] In the above premix, add 8 μm silicon oxide powder 794.5g and 1.8 μm silicon oxide powder 340.5g (mass fraction is 47.5%), dispersant sodium polyacrylate 8ml (0.7% of ceramic powder mass), add powder each time After ball milling for 3 hours, finally add 12ml (1.2% of the mass of the premix) photoinitiator 1173 (2-hydroxyl-methylphenylpropan-1-one), ball milling for 1 hour, so that the photoinitiator and the slurry are fully mixed , to obtain a uniformly dispersed ceramic slurry.

[0042] Add the ceramic slurry into the resin tank of the light-curing molding machine (SPS450B, manufactured by Shaanxi Hengtong Intelligent Machine Co., Ltd.); use the 3D solid modeling software PRO / E to process the 3D model of the blade to obtain the 3D solid model of the blade casting mold ; Import the three-...

Embodiment 3

[0046] Weigh 525g of deionized water and 225g of glycerin, mix them to dissolve each other, add 450g of acrylamide and 50g of N-N'methylenebisacrylamide into the above solution, and dissolve them completely to obtain a transparent premix.

[0047] In the above-mentioned premixed liquid, add 5 μ m silicon oxide powder 1766g (mass fraction is 58.5%) successively, dispersant ammonium polyacrylate 9ml (being 0.5% of ceramic powder mass), ball mill 3 hours after adding powder each time, finally add 18ml ( The photoinitiator 1173 (2-hydroxy-methylphenylpropane-1-one), which is 1.8% of the mass of the premix solution, was ball milled for 1 hour to fully mix the photoinitiator and the slurry to obtain a uniformly dispersed ceramic slurry.

[0048] Add the ceramic slurry into the resin tank of the light-curing molding machine (SPS450B, manufactured by Shaanxi Hengtong Intelligent Machine Co., Ltd.); use the 3D solid modeling software PRO / E to process the 3D model of the blade to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com