Anti-oxidation coating and preparation method thereof

An anti-oxidation and coating technology, applied in the field of preparation of anti-oxidative coatings, can solve the problems of high coating preparation temperature, difficult to control coating thickness and composition, etc., and achieve excellent anti-oxidation performance and excellent high-temperature anti-oxidation. Ability, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

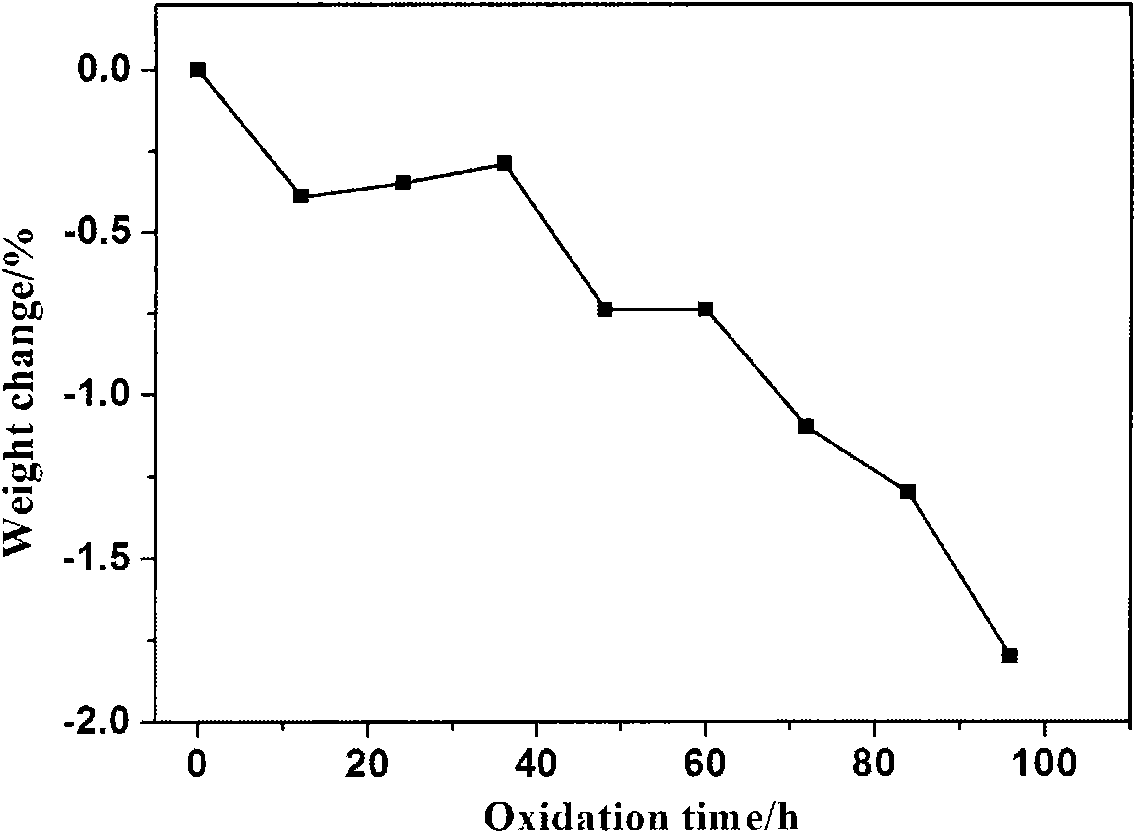

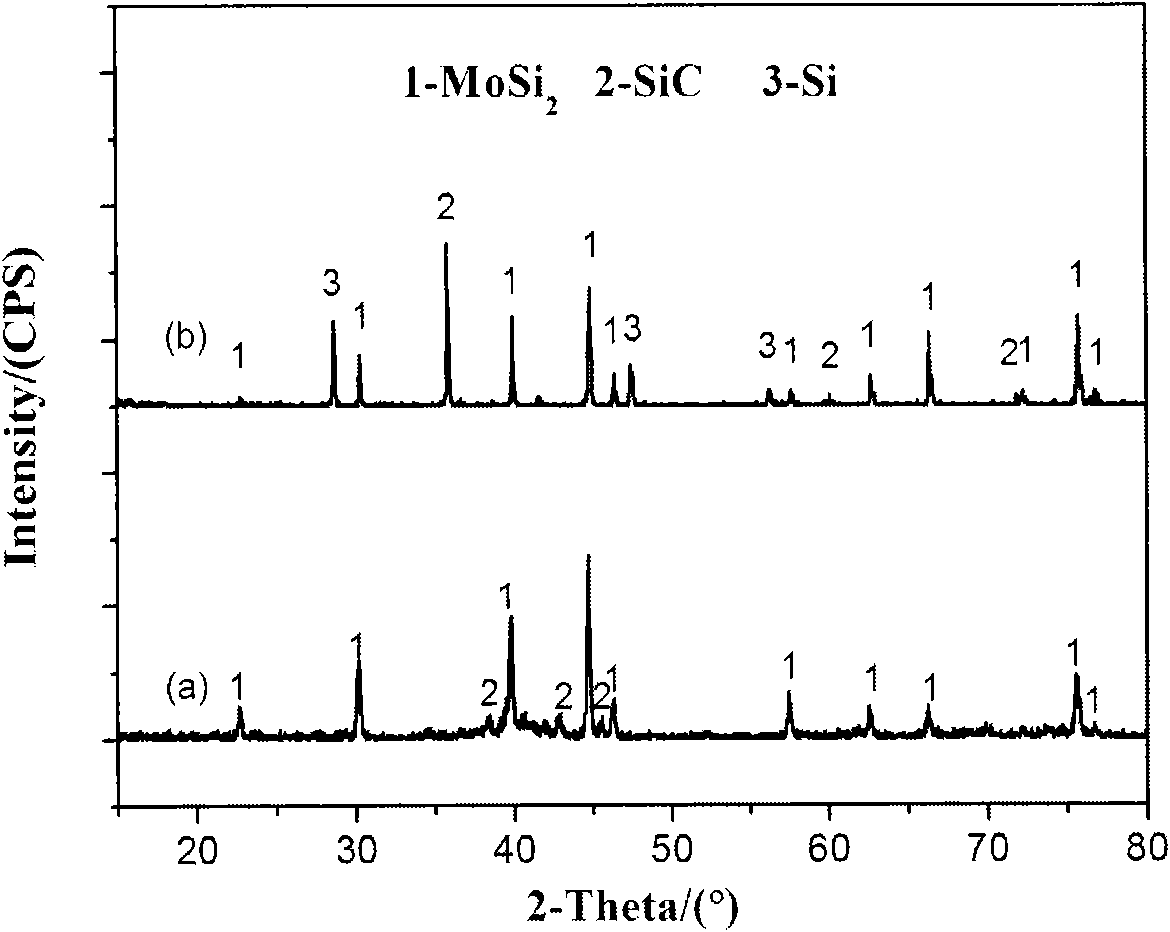

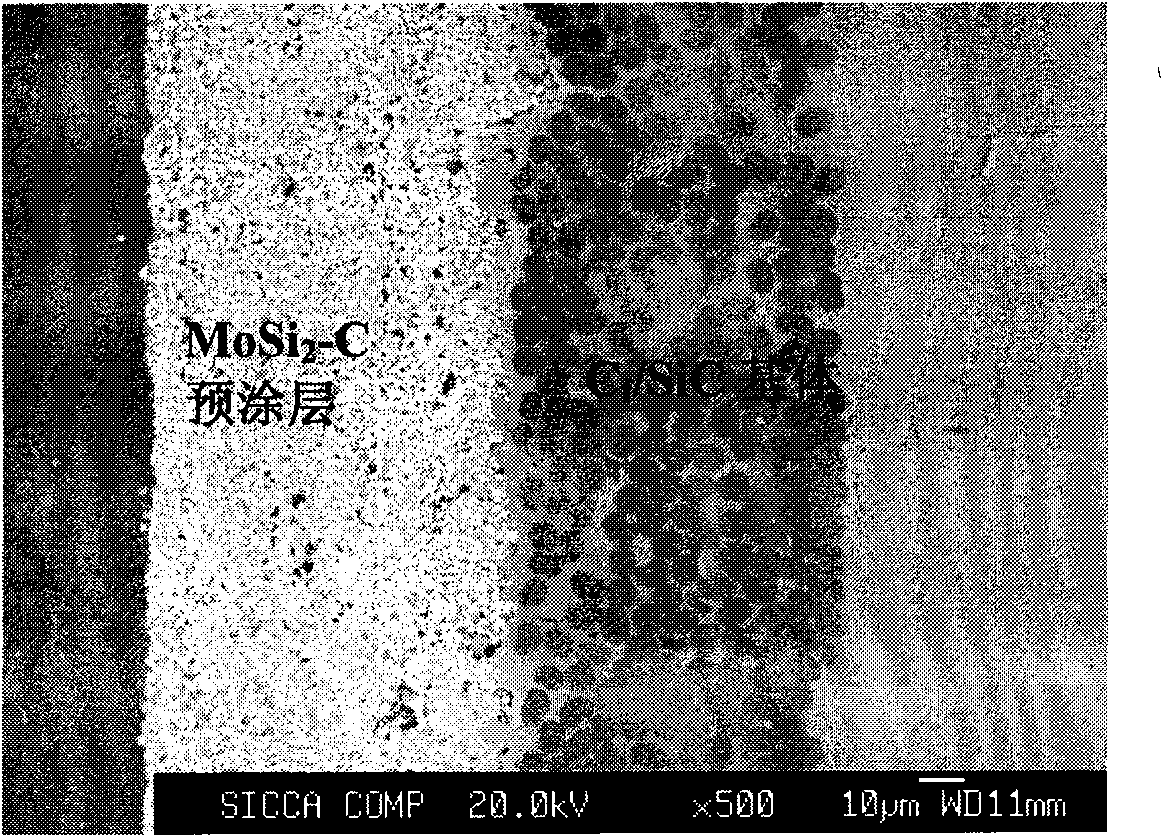

[0027] Use thermosetting phenolic resin as binder and carbon source, and use absolute ethanol as solvent to make MoSi2 into a slurry. The mass ratio of MoSi2 to thermosetting phenolic resin is 2.5:1, and the solid content of the slurry is ~1g / ml. The method of coating is to coat MoSi2 particles on the Cf / SiC composite material, after curing and drying, the Cf / SiC composite material coated with MoSi2 slurry is subjected to high temperature treatment (1000°C), and then the slurry is coated with a pre-coating layer. Such as figure 2 and image 3 shown. Then put the processed sample into a vacuum carbon tube furnace, use silicon powder for experiment as the silicon source, control the reaction temperature at 1500°C, and the reaction time is 1.5 hours, and prepare a MoSi2-SiC-Si coating with a thickness of ~ 120μm, the volume ratio of MoSi2 to SiC is about 3:1, and the content of free Si is about 5vol% of the coating. Such as Figure 4 and Figure 5 shown.

example 2

[0029]Use thermosetting phenolic resin as binder and carbon source, and use absolute ethanol as solvent to make Mo into a slurry. The mass ratio of Mo to thermosetting phenolic resin is 3.5:1, and the solid content of the slurry is ~2g / ml. The method of coating is to coat Mo particles on the Cf / SiC composite material, and after curing and drying, perform high temperature treatment (1000° C.) on the Cf / SiC composite material coated with Mo slurry, and then coat the slurry with a precoat. Then put the processed sample into a vacuum carbon tube furnace, use silicon powder for the experiment as the silicon source, control the reaction temperature at 1500 ° C, and the reaction time is 2 hours, and prepare a MoSi2-(Mo5Si3)-SiC-Si coating. Its thickness is ~120μm, the volume ratio of MoSi2-(Mo5Si3) to SiC is about 3:1, and the free Si content is about 5vol% of the coating.

example 3

[0031] Use thermosetting phenolic resin as binder and carbon source, and use water as solvent to prepare WSi2 into a slurry. The mass ratio of WSi2 to thermosetting phenolic resin is 4:1, and the solid content of the slurry is ~1.5g / ml. The coating method is to coat WSi2 particles on the Cf / SiC composite material, and after curing and drying, perform high temperature treatment (1000°C) on the Cf / SiC composite material coated with WSi2 slurry, and then coat the slurry with a precoat. Then put the processed sample into a vacuum carbon tube furnace, use silicon powder for experiment as the silicon source, control the reaction temperature at 1500°C, and the reaction time is 1.5 hours, and prepare a WSi2-SiC-Si coating with a thickness of ~ 120μm, the volume ratio of WSi2 and SiC is about 3:1, and the content of free Si is about 5vol% of the coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com