Method for preparation of nano-modified amorphous ceramic coating on metal matrix ceramic coating

A technology of ceramic coating and metal substrate, applied in the field of preparing nano-modified amorphous ceramic coating, which can solve the problems of peeling and corrosion resistance, and achieve the effects of low through-hole rate, simple preparation process and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

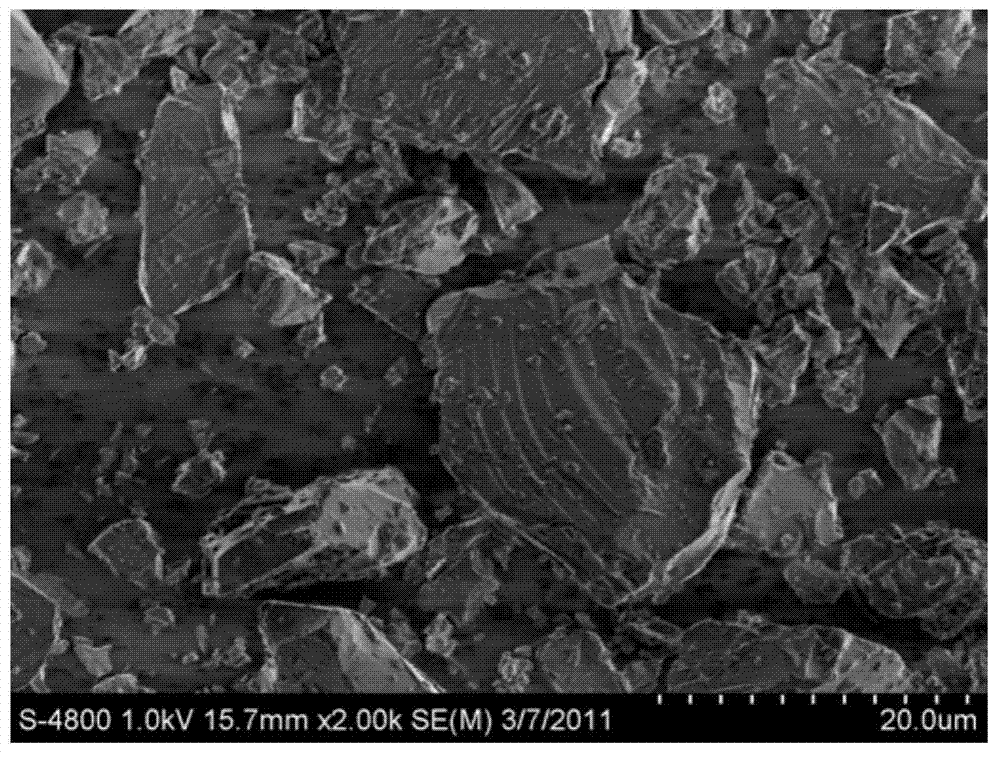

[0064] The first step is to prepare a ceramic coating on the surface of the metal substrate by plasma spraying

[0065] Adopt the known plasma spraying method of this technical field to prepare ZrO on the Fe-Al alloy matrix surface of a workpiece 2 ceramic coating, and remove the floating dust on the surface, in preparation for the ZrO 2 Preparation of nano-modified amorphous ceramic coating on ceramic coating;

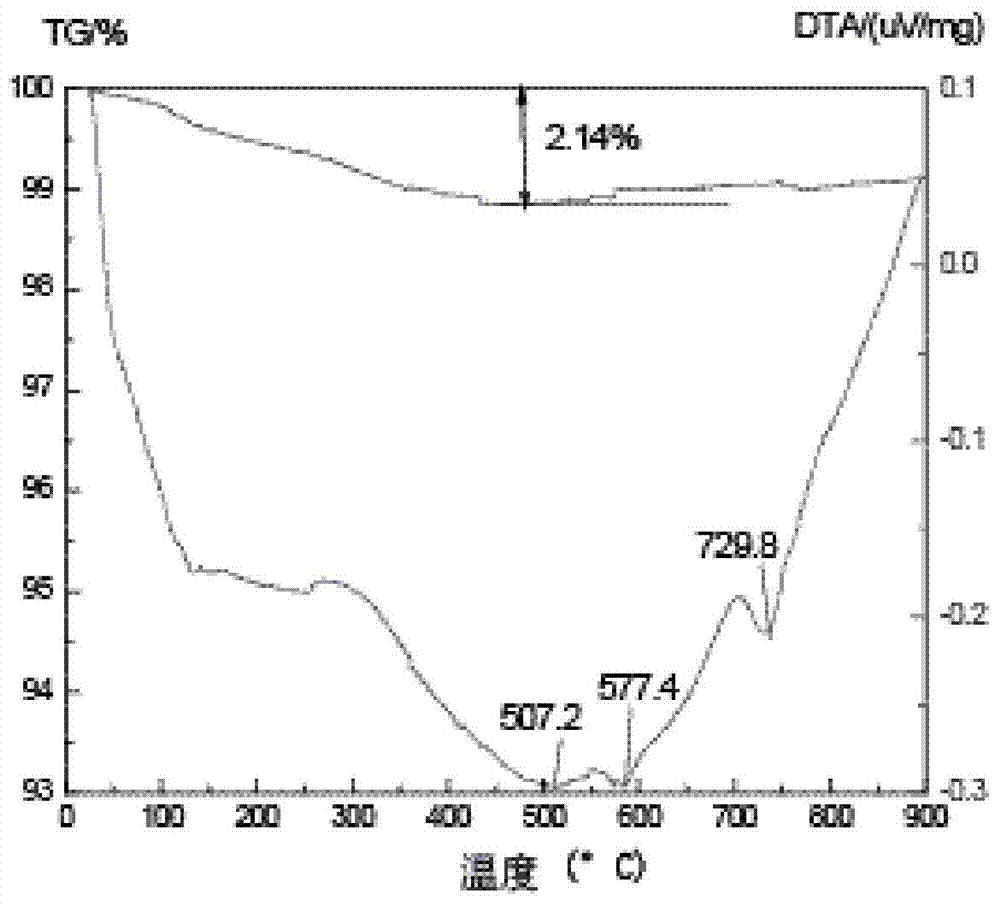

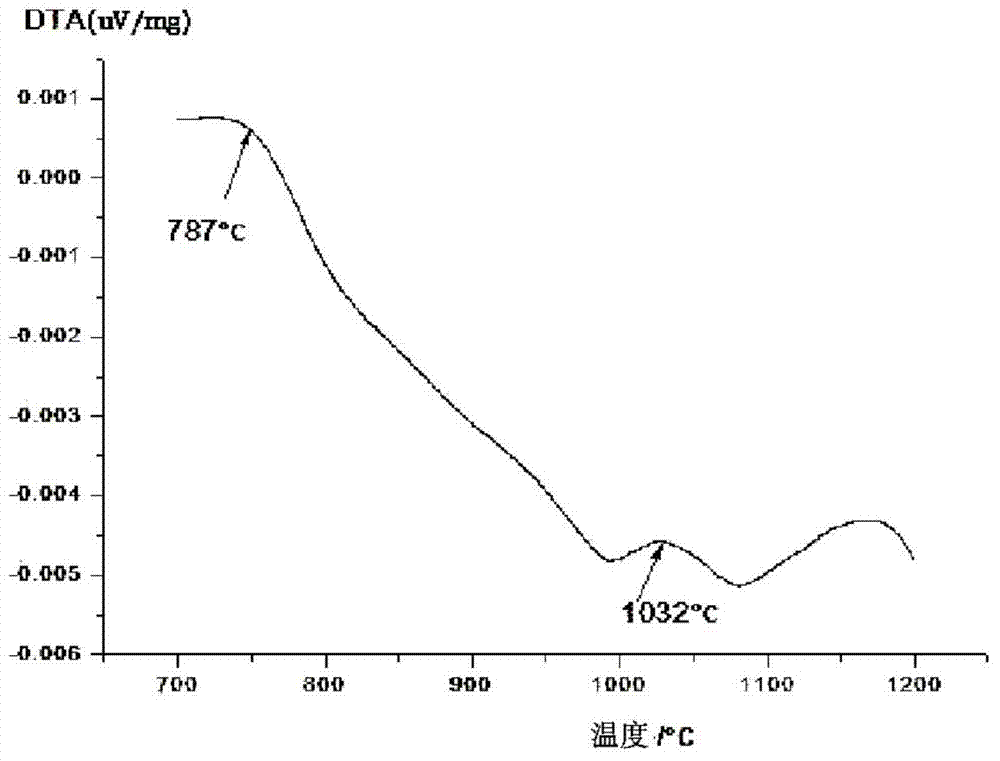

[0066] The second step is to prepare nanocrystalline ceramics + amorphous ceramics mixed powder

[0067] (2.1) Configuration of raw materials

[0068] The nanocrystalline ceramic powder used is Y-ZrO 2 Powder, the amorphous ceramic powder used is made of 10.0% B 2 o 3 , 3.0%Al 2 o 3 , 8.0%CaO, 2.5%MgO, 6.5%K 2 O, 8.5%Na 2 O and the rest are SiO 2 The mixed powder of composition, the composition distribution ratio of nanocrystalline ceramics+amorphous ceramic mixed powder is: nanocrystalline ceramic powder accounts for 3.0%, and the rest is amorphous ceramic ...

Embodiment 2

[0094] The first step is to prepare a ceramic coating on the surface of the metal substrate by plasma spraying

[0095] With embodiment 1;

[0096] The second step is to prepare nanocrystalline ceramics + amorphous ceramics mixed powder

[0097] (2.1) Configuration of raw materials

[0098] The nanocrystalline ceramic powder used is nano Y-ZrO 2 Powder, the amorphous ceramic powder used is made of 14.0%B 2 o 3 , 2.5%Al 2 o 3 , 8.5%CaO, 2.5%MgO, 5.0%K 2 O, 9.5%Na 2 O and the rest are SiO 2 The amorphous ceramic mixed powder that forms, the composition distribution ratio of nanocrystalline ceramics+amorphous ceramic mixed powder is: nanocrystalline ceramic powder accounts for 10.0%, and the rest is amorphous ceramic mixed powder, and all above-mentioned % are percentages by weight,

[0099] (2.2) Pretreatment of nanocrystalline ceramic powder

[0100] Weigh nanometer Y-ZrO according to the ratio described in step (2.1) 2 powder, put it into an ion oscillator for depol...

Embodiment 3

[0117] The first step is to prepare a ceramic coating on the surface of the metal substrate by plasma spraying

[0118] With embodiment 1;

[0119] The second step is to prepare nanocrystalline ceramics + amorphous ceramics mixed powder

[0120] (2.1) Configuration of raw materials

[0121] The nanocrystalline ceramic powder used is Y-ZrO 2 Powder, the amorphous ceramic powder used is made of 8.0% B 2 o 3 , 2.5%Al 2 o 3 , 8.5%CaO, 2.5%MgO, 5.5%K 2 O, 10.0%Na 2 O and the rest are SiO 2 The amorphous ceramic mixed powder that forms, the composition distribution ratio of nanocrystalline ceramics+amorphous ceramic mixed powder is: nanocrystalline ceramic powder accounts for 10.0%, and the rest is amorphous ceramic mixed powder, and all above-mentioned % are percentages by weight,

[0122] (2.2) Pretreatment of nanocrystalline ceramic powder

[0123] Weigh nanometer Y-ZrO according to the ratio described in step (2.1) 2 powder, put it into an ion oscillator for depolymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com