Al/Al2O3 heat storage material and preparation method thereof

A heat storage material and matrix material technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., to achieve the effects of enhancing mechanical properties and stability, facilitating large-scale production, and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

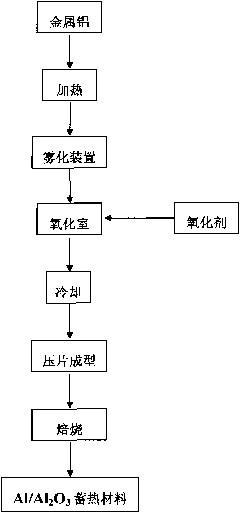

Method used

Image

Examples

Embodiment 1

[0023] 1) Implementation conditions

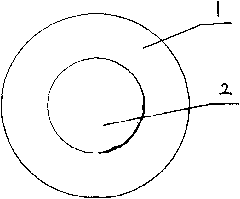

[0024] The aluminum liquid is atomized using an atomizing device at 700°C, and the atomized droplets are cooled in an oxidation chamber at 400°C. The oxidizing atmosphere is water vapor, and argon is used as the water vapor carrier gas. The grain size (diameter) of the Al2O3 / Al heat storage material obtained after cooling is 1000 μm, and the diameter (diameter) of the metallic aluminum core is 600 μm. Press the sample machine at a pressure of 12Mpa and a pressure holding time of 20min. Of compacts. Sintering in a sintering kiln with an air atmosphere, heat preservation and sintering at 800°C for 1.5 hours to obtain a finished product.

[0025] 2) Implementation results

[0026] The sintering strength of the finished product is very high. The coefficient of thermal expansion is 0.12 and the sintered density is 2.87g / cm 3 , The porosity is 16-21%, the thermal conductivity is 34.98w / m·k, and the heat storage density at 800-825°C is 1520kJ / kg.

Embodiment 2

[0028] 1) Implementation conditions

[0029] The aluminum liquid is atomized using an atomizing device at 700°C, and the atomized droplets are cooled in an oxidation chamber at 500°C, and the oxidizing atmosphere is carbon dioxide. The grain size (diameter) of the Al2O3 / Al heat storage material obtained after cooling is 1500 μm, and the diameter (diameter) of the metallic aluminum core is 700 μm. Press the sample machine at a pressure of 12Mpa and a pressure holding time of 20min. Of compacts. Sintering in a sintering kiln with an air atmosphere, heat preservation and sintering at 800°C for 1.5 hours to obtain a finished product.

[0030] 2) Implementation results

[0031] The sintering strength of the finished product is very high. The coefficient of thermal expansion is 0.16 and the sintered density is 3.27g / cm 3 , The porosity is 20-25%, the thermal conductivity is 30.48w / m·k, and the heat storage density at 800-825℃ is 1320kJ / kg.

Embodiment 3

[0033] 1) Implementation conditions

[0034] The aluminum liquid is atomized using an atomizing device at 700°C, and the atomized small droplets are cooled in an oxidation chamber at 300°C, and the oxidizing atmosphere is air. The grain size (diameter) of the Al2O3 / Al heat storage material obtained after cooling is 800 μm, and the diameter (diameter) of the metallic aluminum core is 300 μm. Press the sample machine at a pressure of 12Mpa and a pressure holding time of 20min. Of compacts. Sintering in a sintering kiln with an air atmosphere, heat preservation and sintering at 800°C for 1.5 hours to obtain a finished product.

[0035] 2) Implementation results

[0036] The sintering strength of the finished product is very high. The coefficient of thermal expansion is 0.12, and the sintered density is 2.68g / cm 3 , The porosity is 18-22%, the thermal conductivity is 40.48w / m·k, and the heat storage density at 800-825℃ is 1520kJ / kg.

[0037] The oxidizing atmosphere of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Sintered density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com