Stripping solution for sintered neodymium-iron-boron surface aluminum coating

A technology of aluminum coating and deplating solution, which is applied in the field of deplating solution, can solve the problems of sintered NdFeB substrate with large damage, defective or waste products, and non-recyclability, etc., to achieve low production cost, improve stability, and quickly Uniform fade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

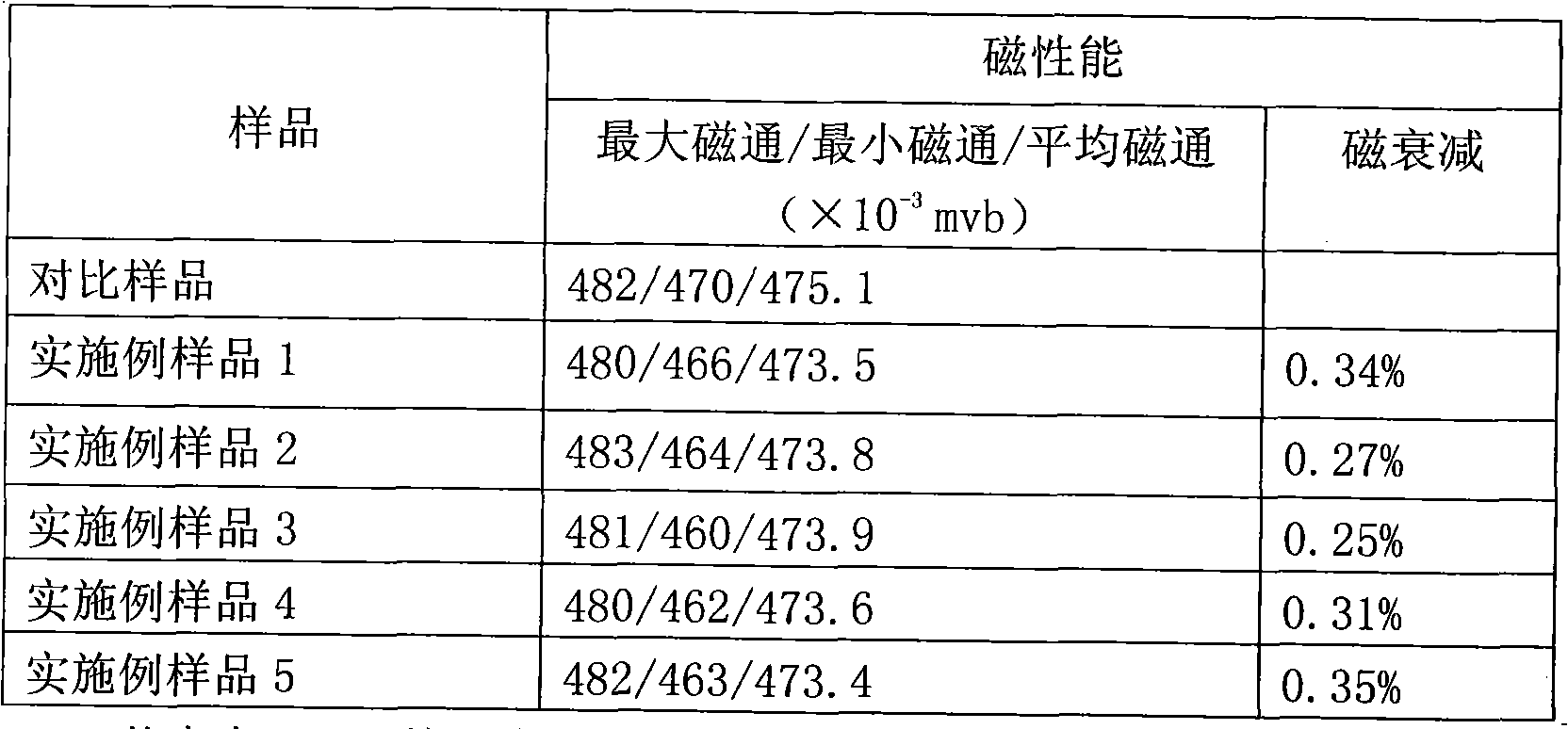

Examples

Embodiment 1

[0020] Embodiment 1: the solvent of the aluminum coating on the surface of sintered NdFeB is deionized water, and the components and contents of the solute are as follows:

[0021] Sodium hydroxide 20g / L;

[0022] Sodium carbonate 150g / L;

[0023] Complexing agent: sodium tripolyphosphate 4g / L;

[0024] Corrosion inhibitor: triammonium citrate 1g / L;

[0025] Surfactant: sodium dodecylbenzenesulfonate 3g / L.

[0026] Select 20 samples from the magnetic steel and soak them in the deplating solution of this embodiment, the aluminum coating on the surface of the magnetic steel will be removed quickly and evenly, and the deplating will be completed within 1 to 3 minutes, and the samples will be taken out, ultrasonically cleaned and dried as an example Sample 1.

Embodiment 2

[0027] Embodiment 2: the solvent of the aluminum coating on the surface of sintered NdFeB is deionized water, and the components and contents of the solute are as follows:

[0028] Sodium hydroxide 50g / L;

[0029] Sodium carbonate 200g / L;

[0030] Complexing agent: sodium tripolyphosphate 4g / L;

[0031] Corrosion inhibitor: triammonium citrate 3g / L;

[0032] Surfactant: sodium dodecylbenzenesulfonate 4g / L.

[0033] Select 20 samples in the magnetic steel and soak them in the deplating solution of this embodiment, the aluminum coating on the surface of the magnetic steel will be removed quickly and evenly, and the deplating will be completed within 1 to 3 minutes. The samples will be taken out, cleaned with ultrasonic waves, and dried as an implementation. Example sample 2.

Embodiment 3

[0034] Embodiment 3: The solvent of the aluminum coating on the surface of sintered NdFeB is deionized water, and the components and contents of the solute are as follows:

[0035] Sodium hydroxide 30g / L;

[0036] Sodium carbonate 180g / L;

[0037] Complexing agent: sodium citrate 4g / L;

[0038] Corrosion inhibitor: hexamethylenetetramine 2g / L;

[0039] Surfactant: polyethylene glycol 4g / L.

[0040] Select 20 samples in the magnetic steel and soak them in the deplating solution of this embodiment, the aluminum coating on the surface of the magnetic steel will be removed quickly and evenly, and the deplating will be completed within 1 to 3 minutes. The samples will be taken out, cleaned with ultrasonic waves, and dried as an implementation. Example sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com