Preparation method of Al3Sc-Al3Zr/Al composite material inoculant

A technology of al-sc-zr and composite materials, which is applied in the field of aluminum-based alloys, can solve the problems of high product cost, nucleation particle dispersion or dispersion degree, large particle size, and excessive particle size, so as to save production cost, Reduce the dosage and enhance the effect of aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The first step, the preparation of raw materials:

[0038] Take the master alloy whose mass percentage is Al-5Sc and the master alloy whose mass percentage is Al-40Zr in the commercially available component content of the required amount, according to the mass percentage of each component element in the target alloy: Sc 2.00%, Zr 1.00%, and the rest Al, for raw material preparation

[0039] The second step, the in-situ synthesis preparation of bulk Al-Sc-Zr master alloy:

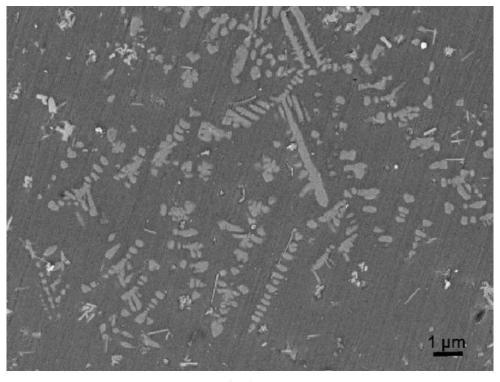

[0040] Put the commercially purchased Al-5Sc master alloy and commercially purchased Al-40Zr master alloy weighed in the first step above into the crucible of WK-II non-consumable vacuum electric arc furnace for melting, the vacuum degree is 5×10 -3 Pa, using high temperature of electric arc heating, the melting temperature is 2000K, melt all the master alloys added, keep it warm for 10 minutes, then cool down with the copper crucible with water cooling device in the furnace until the melted master a...

Embodiment 2

[0046] The first step, the preparation of raw materials:

[0047] Take the master alloy whose mass percentage is Al-5Sc and the master alloy whose mass percentage is Al-40Zr in the commercially available component content of the required amount, according to the mass percentage of each component element in the target alloy: Sc 1.00% for Zr, 1.00% for Zr, and the rest for Al, for raw material preparation

[0048] The second step, the in-situ synthesis preparation of bulk Al-Sc-Zr master alloy:

[0049] With embodiment 1;

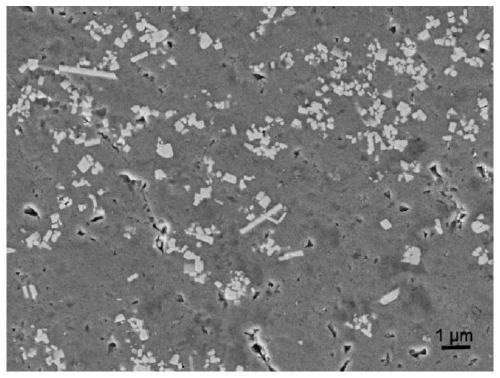

[0050] The third step, ultrasonic treatment of bulk Al-Sc-Zr master alloy:

[0051] Heat the bulk Al-Sc-Zr master alloy prepared in the second step above until it melts and then perform ultrasonic treatment. The ultrasonic power is 670W, the ultrasonic frequency is 27000Hz, and the ultrasonic time is 1.5min. During this process, argon gas is introduced for protection. Pour the melt into a steel mold with a height of 120 mm and a diameter of 20 mm before it...

Embodiment 3

[0055] The first step, the preparation of raw materials:

[0056] Take the master alloy whose mass percentage is Al-5Sc and the master alloy whose mass percentage is Al-40Zr in the commercially available component content of the required amount, according to the mass percentage of each component element in the target alloy: Sc 1.00% for Zr, 2.00% for Zr, and the rest for Al, for raw material preparation

[0057] The second step, the in-situ synthesis preparation of bulk Al-Sc-Zr master alloy:

[0058] With embodiment 1;

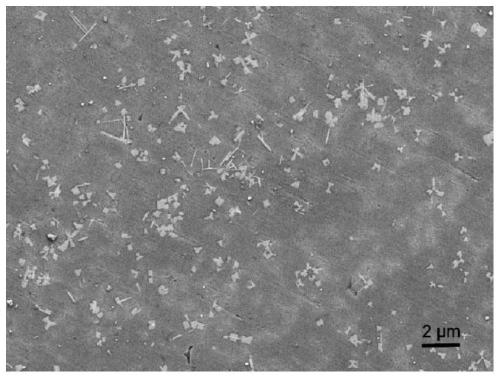

[0059] The third step, ultrasonic treatment of bulk Al-Sc-Zr master alloy:

[0060] Heat the bulk Al-Sc-Zr master alloy prepared in the second step above until it melts, and then perform ultrasonic treatment. The ultrasonic power is 700W, the ultrasonic frequency is 30000Hz, and the ultrasonic time is 2min. During this process, argon gas is introduced for protection. Before the melt solidifies, it is poured into a steel mold with a height of 120 mm and a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com