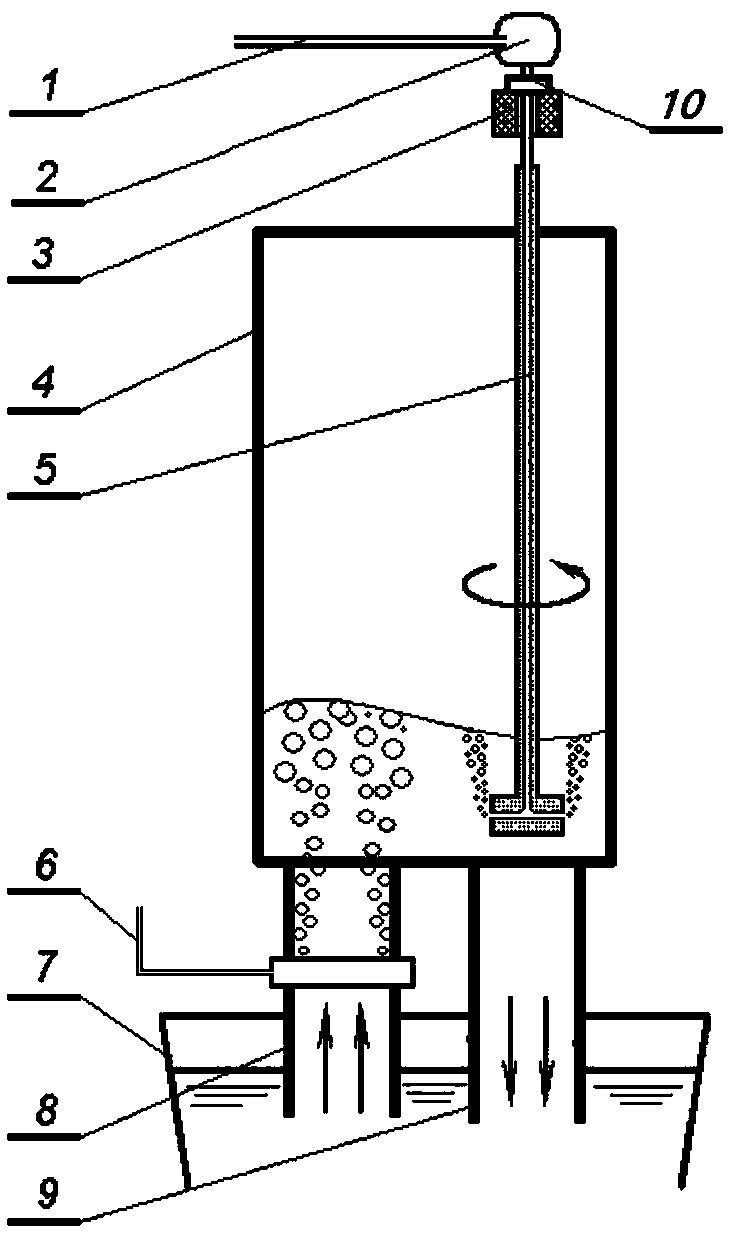

RH refining powder rotary-jetting and dephosphorizing method

A powder spraying and refining technology, applied in the field of iron and steel metallurgy, can solve the problems of slow mass transfer at the slag-steel interface, difficult diffusion of dephosphorization agents, and low utilization rate of powders, so as to improve kinetic conditions, increase residence time, and promote collisions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The implementation plan is carried out on a 180t molten steel tank, the diameter of the upper opening of the molten steel tank is 3200mm, the diameter of the bottom is 2620mm, and the inner height is 4300mm. The diameter of the vacuum chamber is 1760mm, the height of the vacuum chamber is 5120mm, the diameter of the ascending pipe is 600mm, and the diameter of the descending pipe is the same as that of the ascending pipe. Lift the gas injection hole to 630mm from the bottom of the vacuum chamber, and the number of injection holes is 10.

[0020] The total length of the rotary powder spray gun is 2600mm, the length of the inverted T-shaped rotary head is 560mm, the diameter of the stirring head is 220mm, the diameter of the spray hole is 10mm, and the diameter of the hollow tube is 90mm.

[0021] The main components of the described dephosphorization powder contain CaO55%, FeO25%, CaF 2 8%, MnO9%. The particle size of the dephosphorization agent is 0.05mm.

[0022] Th...

Embodiment 2

[0025] The implementation plan is carried out on a 180t molten steel tank, the upper diameter of the molten steel tank is 3120mm, the bottom diameter is 2600mm, and the inner height is 4280mm. The diameter of the vacuum chamber is 1750mm, the height of the vacuum chamber is 5100mm, the diameter of the ascending pipe is 610mm, and the diameter of the descending pipe is the same as that of the ascending pipe. The distance from the lifting gas injection hole to the bottom of the vacuum chamber is 650mm, and the number of injection holes is 12.

[0026] The total length of the rotary powder spray gun is 2750mm, the length of the inverted T-shaped rotary head is 600mm, the diameter of the stirring head is 260mm, the diameter of the spray hole is 11mm, and the diameter of the hollow tube is 100mm.

[0027] The main components of the dephosphorization powder used include CaO50%, FeO23%, CaF 2 12%, MnO 10%, the particle size of the dephosphorization agent is 0.055mm.

[0028] The de...

Embodiment 3

[0031] The implementation plan is carried out on a 180t molten steel tank, the upper diameter of the molten steel tank is 3130mm, the bottom diameter is 2580mm, and the inner height is 4280mm. The diameter of the vacuum chamber is 1750mm, the height of the vacuum chamber is 5100mm, the diameter of the ascending pipe is 580mm, and the diameter of the descending pipe is the same as that of the ascending pipe. Lift the gas injection hole to 650mm from the bottom of the vacuum chamber, and the number of injection holes is 10.

[0032] The total length of the rotary powder spray gun is 2650mm, the length of the inverted T-shaped rotary head is 580mm, the diameter of the stirring head is 290mm, the diameter of the spray hole is 9mm, and the diameter of the hollow tube is 110mm.

[0033] The main components of the dephosphorization powder used contain CaO53%, FeO25%, CaF 2 10%, MnO9%, the particle size of the dephosphorization agent is 0.06mm.

[0034] The dephosphorization steps of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com