590MPa-grade cold-rolled dual-phase steel with excellent hole-expanding performance and production method thereof

A production method and dual-phase steel technology, applied in the field of steel rolling, can solve the problem of low hole expansion performance of 590MPa grade cold-rolled dual-phase steel, achieve excellent hole expansion rate and elongation rate, reduce alloy cost, and improve pourability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

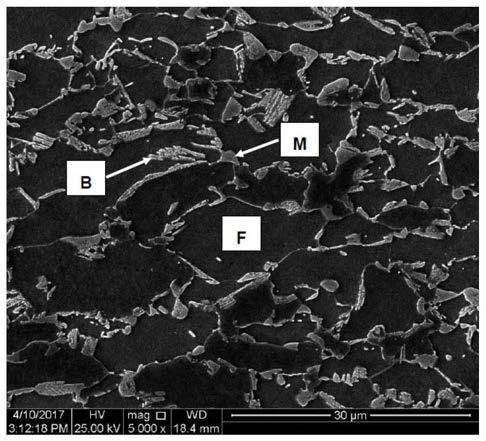

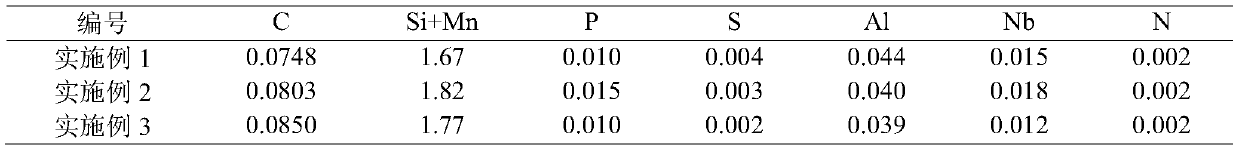

[0053] After molten iron pretreatment, converter smelting, alloy fine-tuning, LF refining, and continuous casting, a dual-phase steel slab with the chemical composition shown in Table 1 below was prepared.

[0054] The chemical composition of table 1 embodiment

[0055]

[0056] Example 1 is used to illustrate: slag removal from molten iron, S content after desulfurization is 0.006%, steel scrap addition is 20 tons, argon blowing mode is adopted for the bottom blowing of the converter, the end point temperature of the converter is controlled at 1650°C, and the target tapping amount is 300 tons. The alloy fine-tuning station adds aluminum particles and carries out bottom blowing argon strong stirring, LF furnace white slag operation, refining exit temperature 1560°C, continuous casting tundish molten steel temperature 1538°C, stopper rod blowing argon operation, so that the crystallizer liquid level does not appear Tossing is appropriate.

[0057] 2) After heating, phosphor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com