Tough high-chrome abrasion-resistant cast ball and preparation method thereof

A wear-resistant casting ball, strong and tough technology, applied in the field of wear-resistant metal materials, can solve the problems of reduced hardness and wear resistance, high tempering temperature, etc., to achieve low cost, lower tempering temperature, and strong process adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

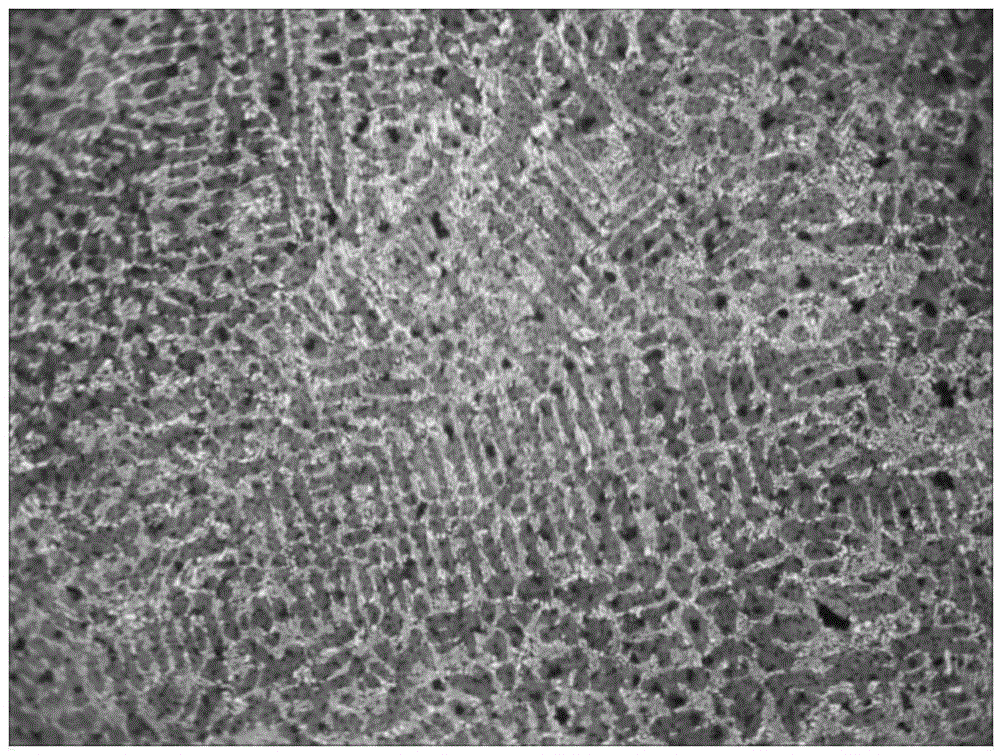

Image

Examples

Embodiment 1

[0027] A tough high chromium wear-resistant casting ball proposed by the present invention, its components include: C: 2wt%, Cr: 12wt%, Si: 0.4wt%, Mn: 0.7wt%, Nd: 0.5wt% %, Si: 2.5wt%, Ti: 0.5wt%, and the rest are Fe and unavoidable impurities.

[0028] The preparation method of the above-mentioned strong and tough high-chromium wear-resistant casting ball proposed by the present invention includes: melting the raw materials in an intermediate frequency induction furnace to obtain alloy liquid evenly, and the melting temperature is 1600°C; feeding the alloy liquid obtained by melting into a mold Casting at constant temperature, the casting temperature is 1400°C, cooling, and demoulding to obtain cast ball billets; heat the cast ball billets obtained from casting to 980°C, keep them warm for 2 hours, send them to the quenching medium to cool, take them out and clean them to obtain quenched ball billets; The quenched ball billet obtained by quenching is sent into the furnace fo...

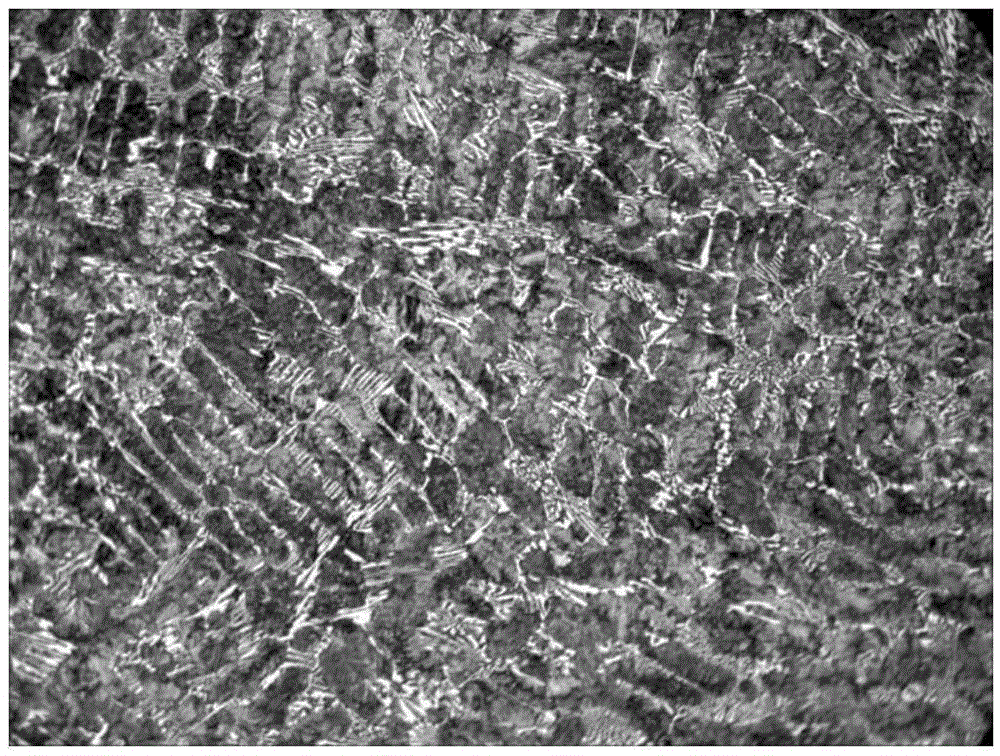

Embodiment 2

[0030] A kind of strong and tough high chromium wear-resistant casting ball proposed by the present invention, its components include by weight percentage: C: 2.2wt%, Cr: 10wt%, Si: 0.6wt%, Mn: 0.5wt%, Nd: 2wt% %, Si: 1wt%, Ti: 2wt%, and the rest are Fe and unavoidable impurities.

[0031] The preparation method of the above-mentioned strong and tough high-chromium wear-resistant casting ball proposed by the present invention includes: melting the raw materials in an intermediate frequency induction furnace to obtain alloy liquid evenly, and the melting temperature is 1550°C; feeding the alloy liquid obtained by melting into a mold Casting at constant temperature, the casting temperature is 1450°C, cooling, demoulding to obtain the cast ball billet; the cast ball billet obtained by casting is heated to 920°C, kept for 4 hours, sent to the quenching medium to cool, taken out and cleaned to obtain the quenched ball billet; The quenched ball billet obtained by quenching is sent i...

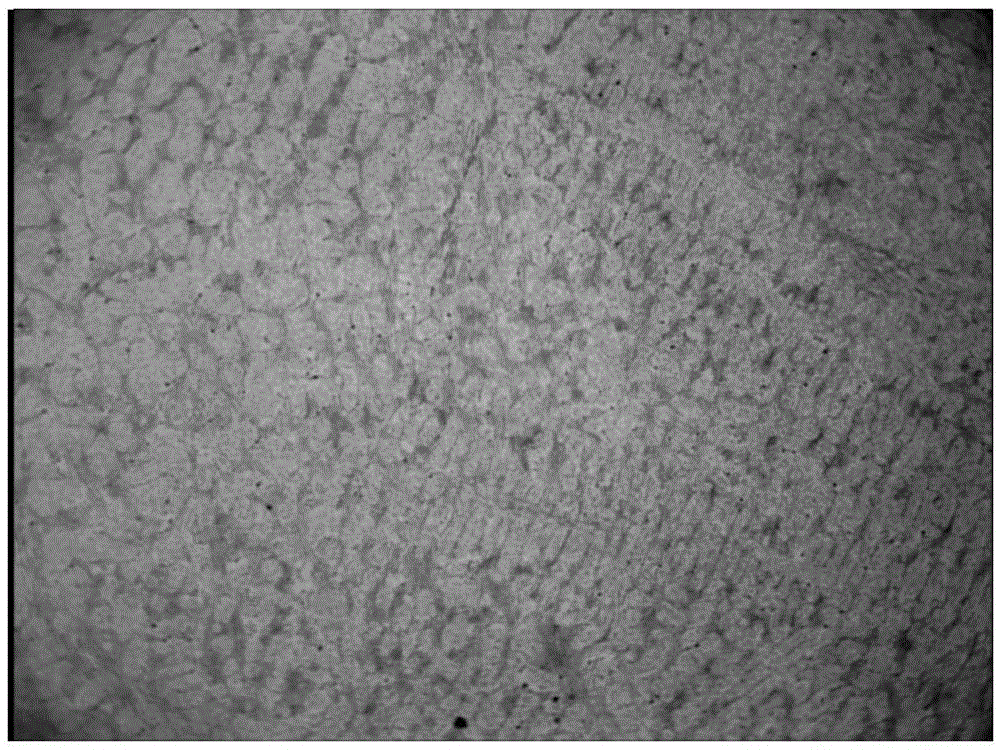

Embodiment 3

[0033] A strong and tough high chromium wear-resistant casting ball proposed by the present invention, its components include: C: 2.05wt%, Cr: 11.5wt%, Si: 0.45wt%, Mn: 0.65wt%, Nd: 1wt%, Si: 2wt%, Ti: 0.8wt%, the rest is Fe and unavoidable impurities.

[0034] The preparation method of the above-mentioned strong and tough high-chromium wear-resistant casting ball proposed by the present invention includes: melting the raw materials in an intermediate frequency induction furnace to obtain alloy liquid evenly, and the melting temperature is 1580°C; feeding the alloy liquid obtained by melting into a mold Casting at constant temperature, the casting temperature is 1420°C, cooling, demoulding to obtain cast ball billet; heat the cast ball billet obtained from casting to 960°C, keep it warm for 2.5h, send it to the quenching medium for cooling, take it out and clean it to obtain quenched ball billet; Put the quenched ball billet obtained by quenching into the furnace for tempering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com