Large-sized hypereutectic high-seleium aluminium alloy billet and preparation method thereof

A high-silicon aluminum alloy and hypereutectic technology, which is applied in the field of large-size hypereutectic high-silicon aluminum alloy billets and their preparation, can solve problems such as lack of courage to explore and overcome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

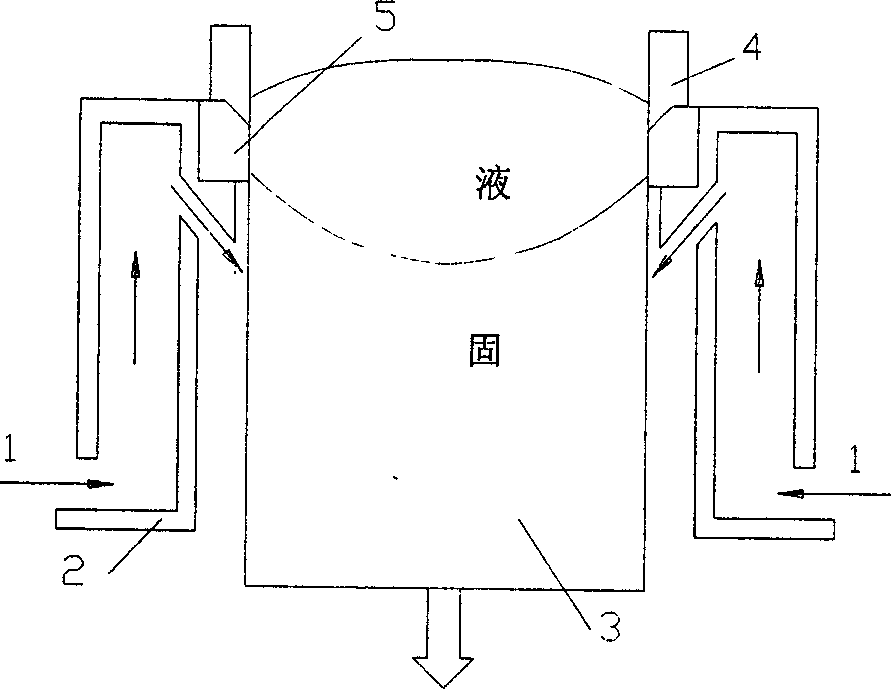

[0034] The selected equipment is self-made equipment, and the structural principle is shown in figure 1 , in the figure 1 cooling water, 2 crystallizer, 3 billet, 4 hot top, 5 graphite ring. The size of the cast billet obtained was a round billet with a diameter of 103 mm and a length of 550 mm.

[0035] The process parameters are:

[0036] Alloy composition: Si15.0% by weight, Fe 0.29% by weight, Cu 0.02% by weight, Al balance;

[0037] Casting temperature: 720°C;

[0038] Vertical traction speed: 85mm / min;

[0039] The amount of cooling water around the solidified billet: 10g / mm.s.

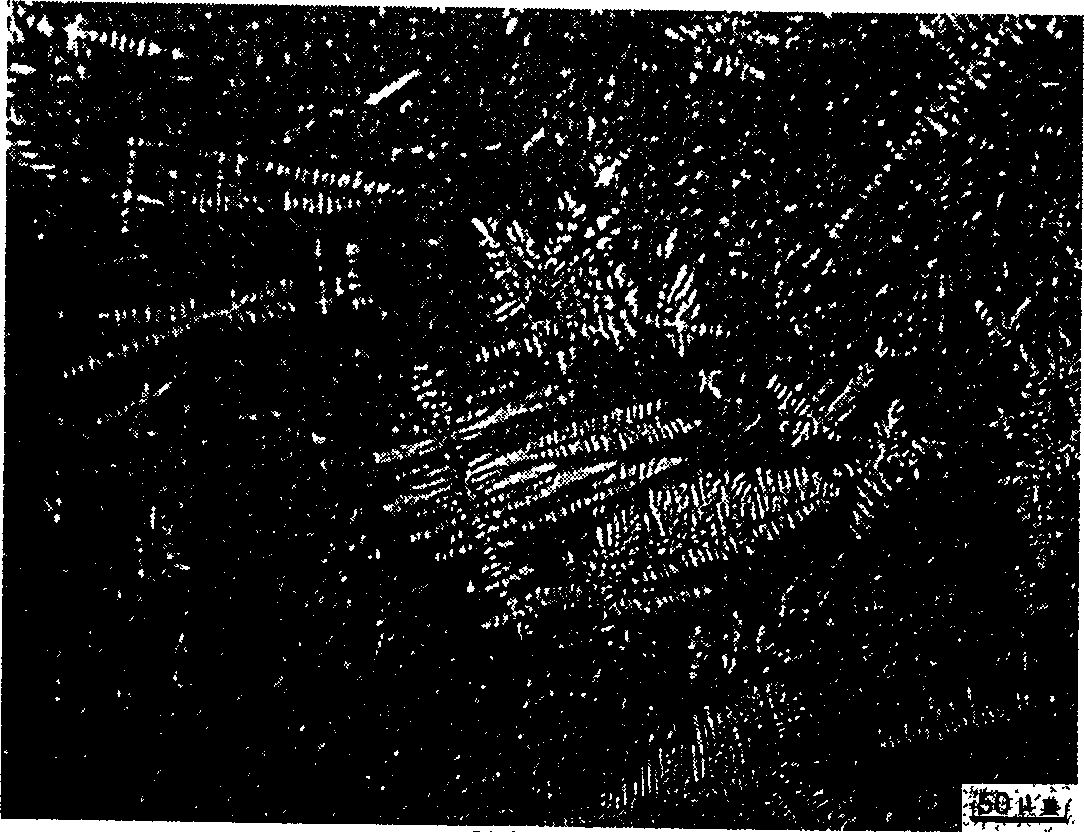

[0040] Metallographic results see figure 2 , 3 , the metallographic results after corroding the aluminum substrate are shown in Figure 4 , it can be seen that the Si particles grow continuously in the three-dimensional direction.

[0041] The heat treatment process parameters are:

[0042] Heating rate: 5°C / min;

[0043] Heating temperature: 450°C, 500°C, 550°C;

[0044] Holding tim...

Embodiment 2

[0047] The selected equipment is self-made equipment, and the structural principle is shown in figure 1 . The size of the cast billet obtained was a round billet with a diameter of 110 mm and a length of 550 mm.

[0048] The process parameters are:

[0049] Alloy composition: Si 20% by weight, Fe 0.39% by weight, Cu 0.017% by weight, Al balance;

[0050] Casting temperature: 820°C;

[0051] Vertical traction speed: 75mm / min;

[0052] The amount of cooling water around the solidified billet: 7g / mm.s.

[0053] Metallographic results see Figure 15 .

[0054] The heat treatment process parameters are:

[0055] Heating rate: 5°C / min;

[0056] Heating temperature: 550°C;

[0057] Holding time: 30 minutes;

[0058] Metallographic results see Figure 16 .

Embodiment 3

[0060] The selected equipment is self-made equipment, and the structural principle is shown in figure 1 . The size of the cast billet obtained is a round billet with a diameter of 80 mm and a length of 5450 mm.

[0061] The process parameters are:

[0062] Alloy composition: Si 30% by weight, Fe 0.23% by weight, Cu 0.015% by weight, Al balance;

[0063] Casting temperature: 1000°C;

[0064] Vertical traction speed: 120mm / min;

[0065] The amount of cooling water around the solidified billet: 15g / mm.s.

[0066] The heat treatment process parameters are:

[0067] Heating rate: 5°C / min;

[0068] Heating temperature: 550°C;

[0069] Holding time: 30 minutes;

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com