Brazing material for SiC ceramic brazing and brazing method

A brazing material and brazing technology, which is applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of inability to ensure the uniformity of the solder composition, unfavorable overall performance of the joint joint, and complicated solder preparation process, etc. problems, to avoid the hazards of toxic elements, good adhesion and wetting properties, low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

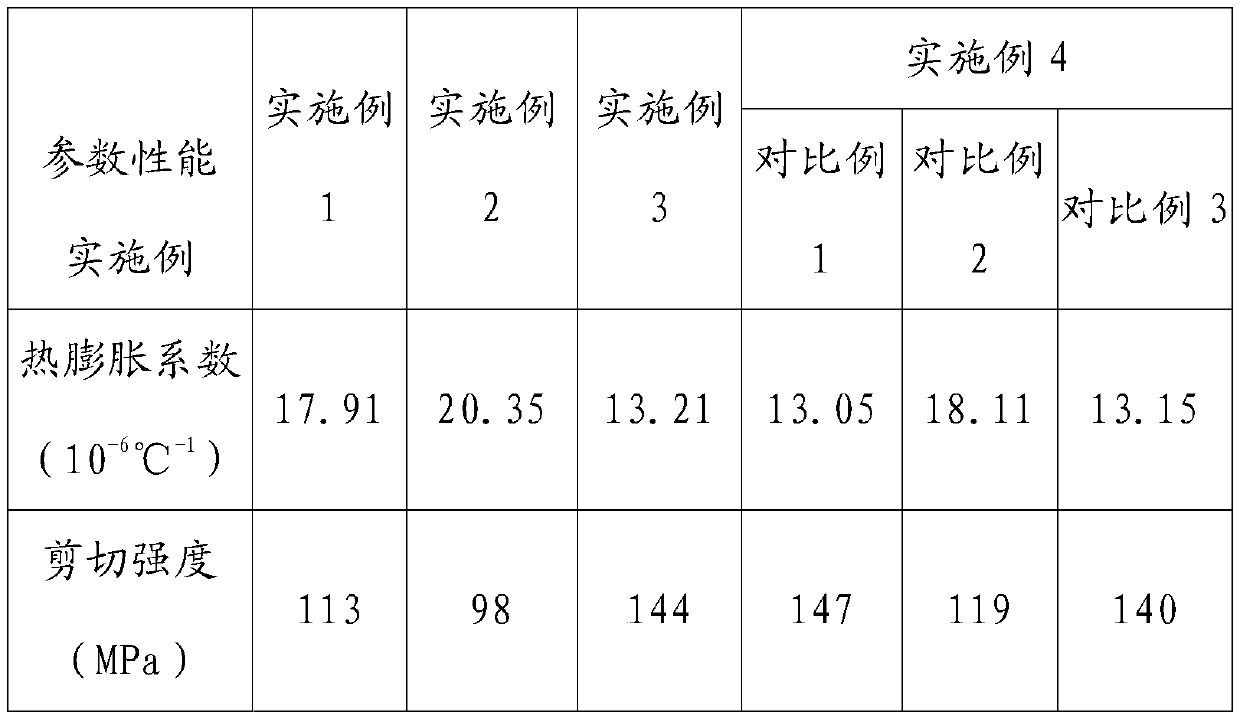

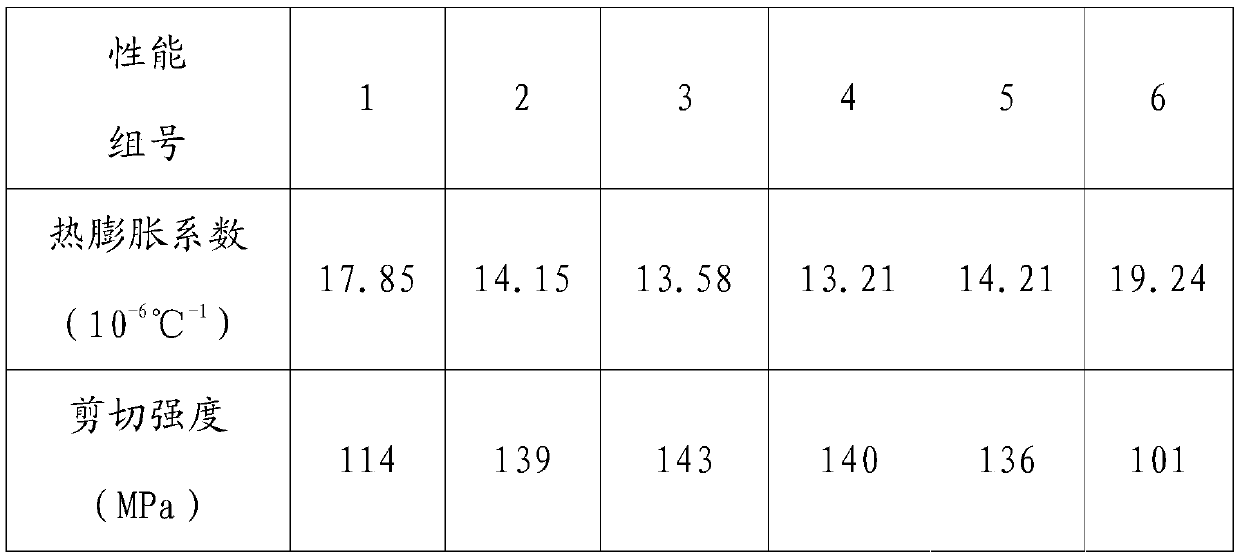

Examples

Embodiment 1

[0029] This embodiment provides a brazing material for brazing SiC ceramics, including components by weight percentage: Ag60%, Cu 28%, Sn 0.5%, Ni 1%, Ti 2.5%, Mo 4%, B 4% , where Ag, Sn, Ni, Cu, Ti powder particle size is The powder particle size of the remaining components is

[0030] The method for brazing by utilizing the above-mentioned brazing material may further comprise the steps:

[0031] S1. Mix all components uniformly by ball milling in proportion, and add oily adhesive to make a paste material (Handy Flo 300 series from Lukes Company, this series of adhesive burns cleanly and has no residue or only a small amount of residue after welding). In this embodiment, the brazing material accounts for 90% by weight, and the oily adhesive accounts for 10%.

[0032] S2, pre-welding pretreatment stage: the surface of the hot-pressed and sintered SiC ceramic sheet (fired by Shanghai Silicate, and made into a SiC ceramic sheet with a size of 16mmX 4mmX 5mm through an inne...

Embodiment 2

[0036] The present embodiment provides a brazing material for SiCk ceramic brazing, comprising components by weight percentage: Ag62%, Cu30%, Sn 0.5%, Ni 0.5%, Ti 2%, Mo 2%, B3%, wherein Ag, Ni, Sn, Cu, Ti powder particle size is The remaining powder particle size is

[0037] The method for brazing by utilizing the above-mentioned brazing material may further comprise the steps:

[0038] S1. After weighing each component in proportion and mixing them uniformly, use a high-vacuum single-roller stripping machine to make an amorphous foil-like material;

[0039] S2. Pre-welding pretreatment stage: the surface of the hot-pressed and sintered SiC ceramic sheet (fired by Shanghai Silicate, and made into a SiC ceramic sheet with a size of 16mmX 4mmX 5mm by an inner circle slicer) is roughly ground on a mechanical grinder , and then, use a diamond grinding paste polishing machine for grinding and smoothing, and use acetone for ultrasonic cleaning Remove impurities, oil stains a...

Embodiment 3

[0043] Present embodiment provides a kind of brazing material that is used for SiCk ceramic brazing, comprises component by weight percentage: Ag40%, Cu 37%, Sn 0.5%, Ni 3%, Ti 4.5%, Mo 7%, B 8% , where Ag, Sn, Ni, Cu, Ti powder particle size is The remaining powder particle size is

[0044] The method for brazing by utilizing the above-mentioned brazing material may further comprise the steps:

[0045] S1. Mix all components uniformly by ball milling in proportion, and add oily adhesive (Handy Flo300 series from Lukes Company, this series of adhesives burns cleanly and has no residue or only a small amount of residue after welding) to make a paste material. In this embodiment, the brazing material accounts for 90% by weight, and the oily adhesive accounts for 10%.

[0046] S2. Pre-welding pretreatment stage: the surface of the hot-pressed and sintered SiC ceramic sheet (fired by Shanghai Silicate, and made into a SiC ceramic sheet with a size of 16mmX 4mmX 5mm by an inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com