Titanium-base cermet, coated cermet, and cutting tool

A technology of cermets and base metals, applied in the field of Ti-based cermets, coated cermets, and cutting tools, can solve problems such as wear or defect, surface damage of finishing, and insufficient improvement effect of cermet hardness, and achieve high toughness , Improve the effect of welding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Using a stainless steel ball mill and superhard grinding beads, the average particle diameter (d 50 value) TiCN powder with an average particle size of 0.6 μm, WC powder with an average particle size of 1.1 μm, TiN powder with an average particle size of 1.5 μm, TaC powder with an average particle size of 2 μm, MoC powder with an average particle size of 1.5 μm, and average particle size NbC powder with an average particle size of 1.5 μm, ZrC powder with an average particle size of 1.8 μm, VC powder with an average particle size of 1.0 μm, Ni powder with an average particle size of 2.4 μm, and Co powder with an average particle size of 1.9 μm. MnCO with a particle size of 5.0 μm 3 Add isopropanol (IPA) to carry out wet mixing in the mixed powder that powder is adjusted in the ratio shown in Table 1, after adding and mixing the paraffin wax of 3 mass %, stamp and form the multi-edged cutter head (throw away tip) tool shape, (a) heating from room temperature to 1200 °C a...

Embodiment 2

[0095] With respect to the cermet multi-edged inserts of Sample Nos. 1 to 11 of Example 1, the atmosphere in the (e) cooling step was changed to the atmosphere in Table 4, and cermets were produced under the same production conditions. The structure of the obtained cermet was observed in the same manner as in Example 1 and is shown in Table 5. In addition, in the depth direction from the surface of the sintered body to the inside, the N content in the inner and surface regions of the cermet was compared by X-ray photoelectron spectroscopic analysis, and the ratio of the N content in the surface region / the inner N content is described in Table 6. . Next, the coating layers shown in Table 6 were formed to obtain multi-edged inserts of Sample Nos. 12 to 18. A cutting test was performed under the same cutting conditions as in Example 1 using the obtained cermet-made multi-blade insert. The results are shown in Table 6 together.

[0096] 【Table 4】

[0097]

[0098] * mark in...

Embodiment 3

[0116] Conditions other than the formulation composition in Table 7 and the conditions in Table 8 were the same as in Example 1, and cermet substrates of Sample Nos. 19 to 31 were obtained.

[0117] 【Table 7】

[0118]

[0119] * mark indicates outside the scope of the present invention

[0120] 1) Raw material composition: MnCO 3 otherwise by mass%

[0121] MnCO 3 Expressed in parts of mass relative to other 100 parts by mass.

[0122] 【Table 8】

[0123]

[0124] * mark indicates outside the scope of the present invention

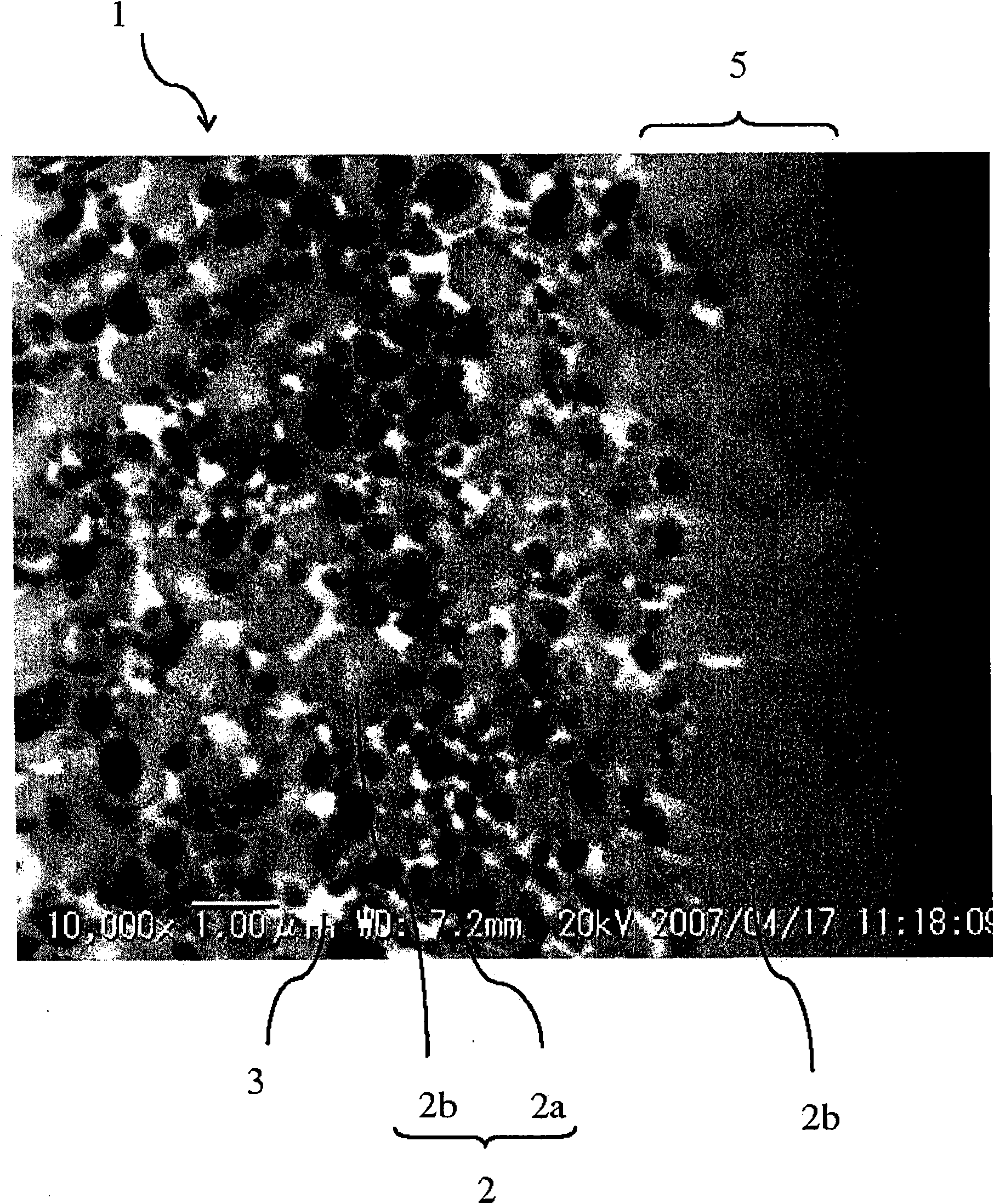

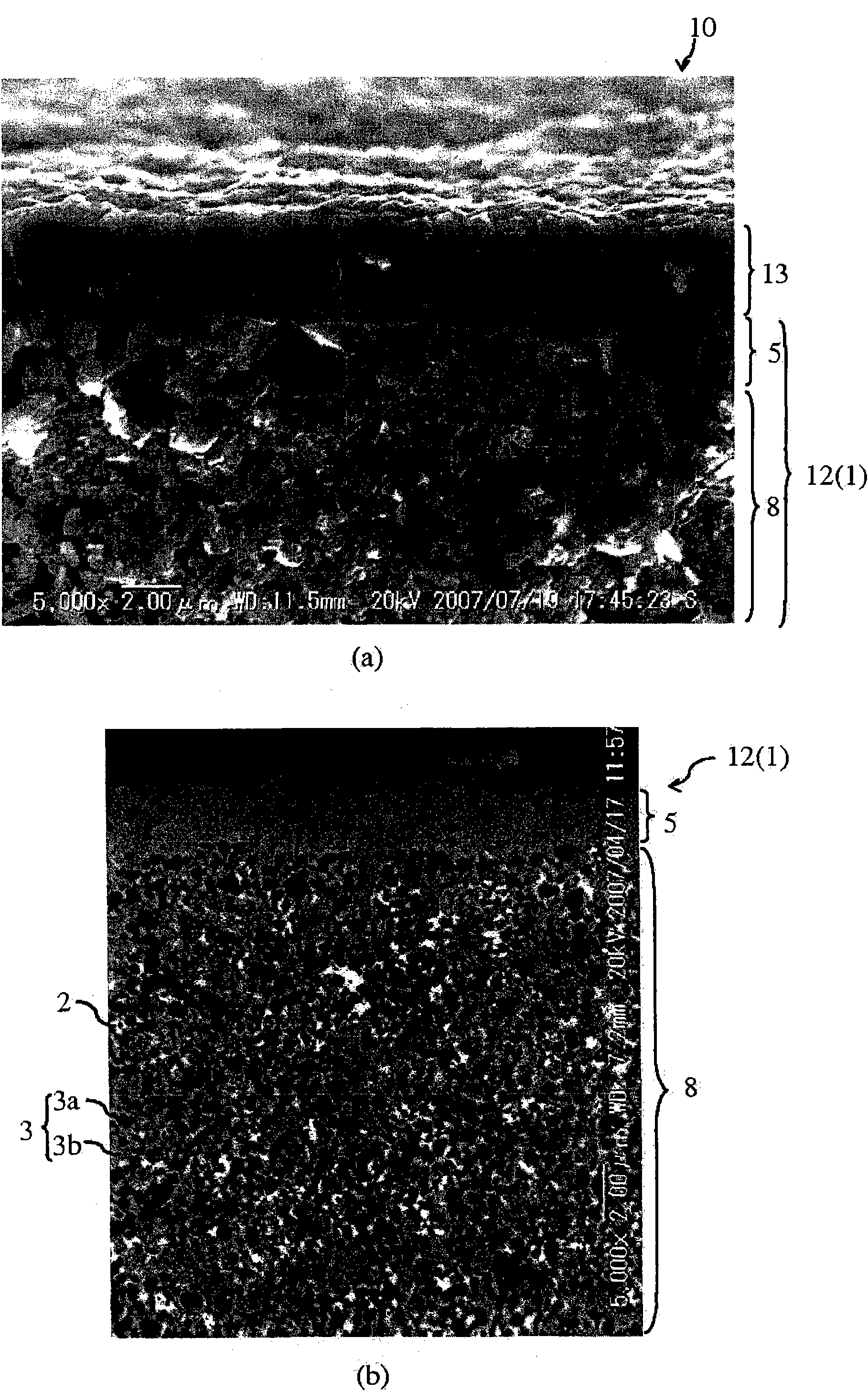

[0125] The obtained cermet substrate was observed using a scanning electron microscope (SEM). In a 10,000 magnification photograph, each of five random parts on the surface and inside was analyzed in an area of 8 μm × 8 μm using commercially available image analysis software. In the image analysis, the existence state of the hard phase and the internal or surface structure state were observed, and the presence or absence of the surface region ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com