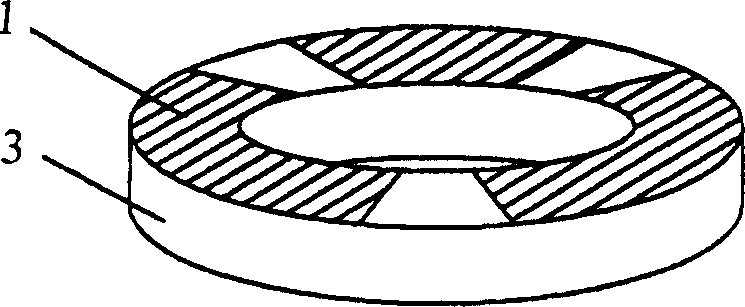

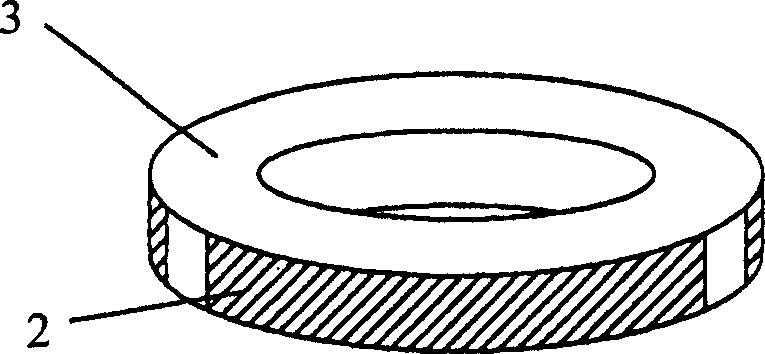

Copper electrode strontium titanate annular piezoresistor and method for making same

A technology of varistors and resistors, applied in the direction of varistors, etc., can solve the problems of unspecified advantages, undisclosed preparation methods of copper electrode strontium titanate ring varistors, etc., and achieve the effect of good welding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The special ceramic material for strontium titanate ring varistor is made by extrusion molding method to make ring green sheet, and after debinding at 650°C, it is sintered at 1350°C in an atmosphere furnace containing nitrogen and hydrogen mixture After the semiconductor ceramic is produced, it is oxidized at 900°C to obtain a strontium titanate ring varistor ceramic substrate. The copper paste that is 80% (weight percentage composition) with Cu content, glass powder content is 15%, solvent content is 5%, is printed on this substrate by 200 mesh screens, (and dry at 150 ℃) ; and after being reduced in an atmosphere furnace containing nitrogen-hydrogen mixed gas at a temperature of 800 ° C, a copper electrode strontium titanate ring varistor is obtained. The weldability of the ring strontium titanate is better through measurement.

Embodiment 2

[0030] The special ceramic material for strontium titanate ring-shaped varistors is made of ring-shaped blanks by extrusion molding, and after debinding at a temperature of 600 ° C, the semiconductor ceramics are sintered at a temperature of 1200 ° C in a hydrogen atmosphere furnace. , Oxidized at 800 ° C to obtain strontium titanate ring varistor ceramic substrate. It is 70% to contain Cu, the glass powder content is 20%, and the copper paste that solvent content is 10% is printed on this substrate by 180 mesh screens, (and dry at the temperature of 100 ℃); After being reduced in a nitrogen atmosphere furnace at 700°C, a copper electrode strontium titanate annular varistor was obtained, and it was measured that the weldability of the annular strontium titanate was better.

Embodiment 3

[0032] The special ceramic material for strontium titanate ring-shaped varistors is made of ring-shaped blanks by dry pressing, and after debinding at a temperature of 750 ° C, the semiconductor ceramics are sintered at a temperature of 1400 ° C in a hydrogen atmosphere furnace. , the strontium titanate annular varistor ceramic substrate was obtained by oxidation at 1000°C. Be 85% with Cu content, glass frit content is 9%, the copper paste that solvent content is 6%, is printed on this substrate by 300 mesh screens, (and dry at the temperature of 200 ℃); After being reduced in a nitrogen atmosphere furnace at 900°C, a copper electrode strontium titanate annular varistor is obtained. According to measurements, the solderability of the annular strontium titanate is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com