Method for preparing structural lipid by enzyme method

A technology of enzymatic preparation and structured lipids, applied in the field of oils and fats, can solve the problems of high consumption of raw and auxiliary materials, low purity, high production costs, etc., and achieve the effect of increasing yield and overcoming high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

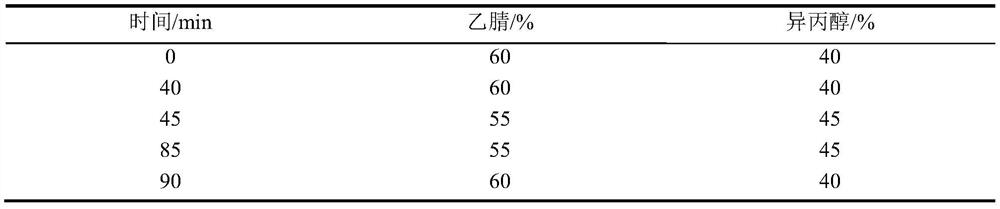

Method used

Image

Examples

Embodiment 1

[0037] The reaction was carried out in a reaction kettle, and 1 g of tripalmitin triglyceride was weighed and mixed with 4 g of ethanol, and 0.05 g of sn-1,3-specific lipase, namely Novozym 435, derived from Candida antarctica was added. Carry out the alcoholysis reaction at 200r / min, 50°C, and magnetically stir for 4h. After the reaction, lipase and impurities were removed by centrifugal filtration at a speed of 4000 r / min, and ethanol was removed by vacuum rotary evaporation at 40°C. Then add n-hexane (1:15) at 20°C for 1 hour to crystallize at a constant temperature. During the crystallization process, the water activity is controlled to be 0.1, and then the liquid part, such as fatty acid ethyl ester and other components with lower melting points, is removed, and the remaining solid part is sn- 2 palmitic acid monoglyceride, analyzed by HPLC-RID, sn-2 palmitic acid monoglyceride content is 73.03%.

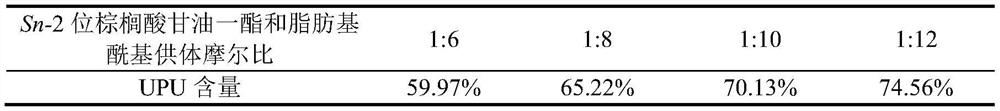

[0038] According to the molar ratio of 1:12, take the above-mentioned sn-...

Embodiment 2

[0040] The reaction was carried out in a reaction kettle, and 1 g of tripalmitin triglyceride was weighed and mixed with 4 g of ethanol, and 0.1 g of sn-1,3-specific lipase, namely Novozym 435, derived from Candida antarctica was added. Carry out the alcoholysis reaction at 200r / min, 50°C, and magnetically stir for 4h. After the reaction, remove lipase and impurities by centrifugal filtration at a speed of 4000r / min, remove ethanol by vacuum rotary evaporation at 40°C, and then add n-hexane (1:15) at 20°C for 1 hour to crystallize, and control the water activity during the crystallization process 0.1, then remove the liquid part that is fatty acid ethyl ester and other components with lower melting points, the remaining solid part is the sn-2 palmitic acid monoglyceride, after HPLC-RID analysis, the sn-2 palmitic monoglyceride content is 78.51%.

[0041] According to the molar ratio of 1:12, take the above-mentioned sn-2 palmitic acid monoglyceride and the fatty acyl donor (i...

Embodiment 3

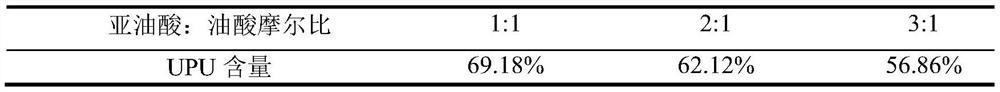

[0043] Step (1) is the same as Example 2, but the mol ratio of linoleic acid and oleic acid in step (2) is modified to 2:1, and all the other parameters are unchanged. As detected by GC, the relative content of sn-2 palmitic acid in the total palmitic acid was 66.81%; as detected by HPLC-ELSD, the content of UPU was 62.12%, see Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com