Silver-copper-indium-titanium middle-temperature brazing filler metal

A technology of soldering and warm brazing, applied in welding/cutting media/materials, welding media, welding equipment, etc., can solve problems such as low content of active element titanium, poor wettability of base metal and seam filling, insufficient activity, etc., to achieve The effect of avoiding cracking and reducing residual thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment technical solution of the present invention will be described in further detail:

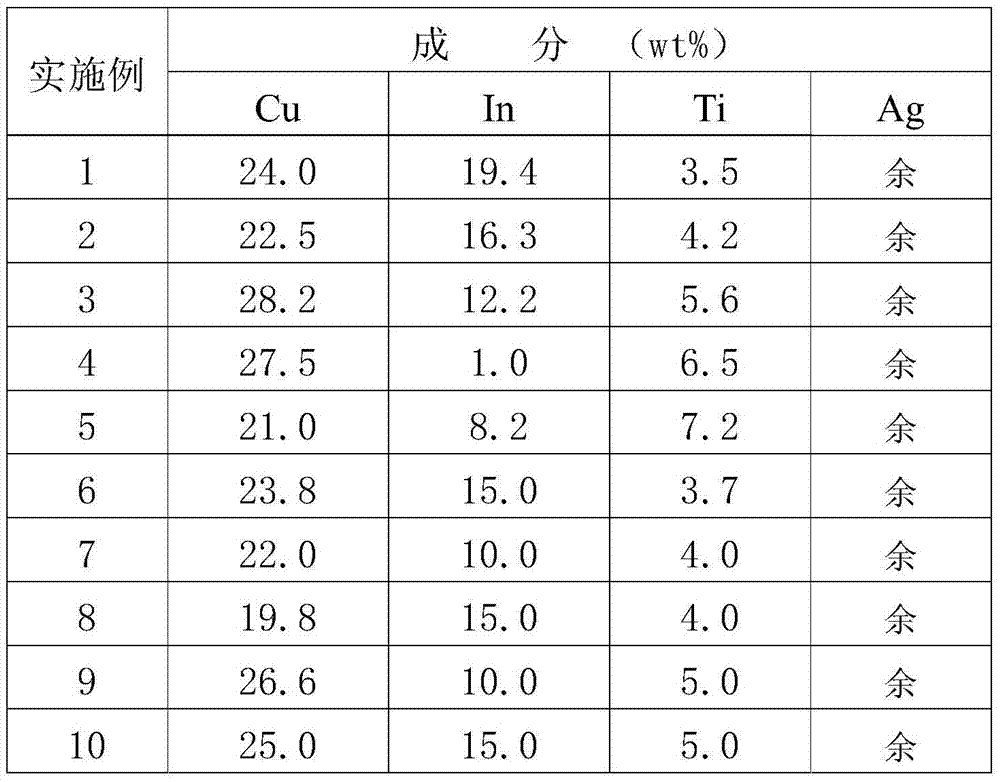

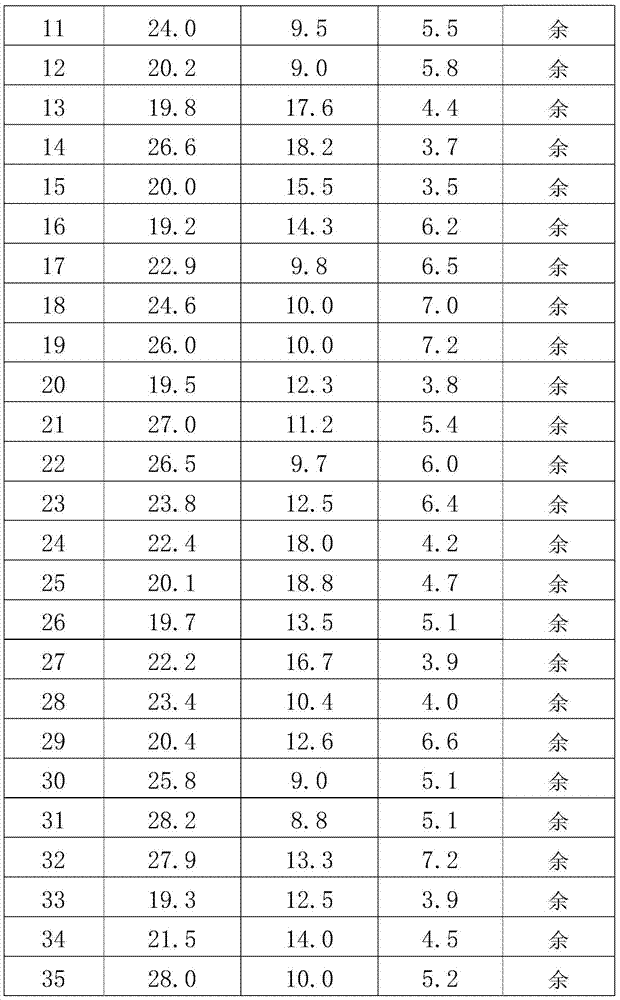

[0014] Table 1 shows the examples of the solder described in the technical solution of the present invention and the chemical composition and weight percentage composition of each example.

[0015]

[0016]

[0017] The above-mentioned brazing material can be used in the form of alloy block, alloy rolling strip, alloy powder, element mixed powder, or quenched foil strip brazing material made by rapid solidification technology as required. The specific preparation method is as follows: For the alloy block, the block of the required shape and size is cut out from the smelted brazing material ingot by machining method; Foil strip preparation equipment Two methods of preparation are strip stripping; powder solder is mainly prepared by mixing pure metal powder in proportion and by atomizing powder.

[0018] The method of brazing using the above high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com