Clean-free solder paste low in ICT (in circuit testing) false positive rate

A technology with no-clean solder paste and false positive rate. It is used in welding media, welding/cutting media/materials, metal processing equipment, etc. It can solve the problem of high viscosity, deterioration of probe piercing residual contact solder metal performance, and impact on electronic assembly. Manufacturing industry production efficiency and other issues to achieve the effect of improving durability and avoiding test misjudgments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

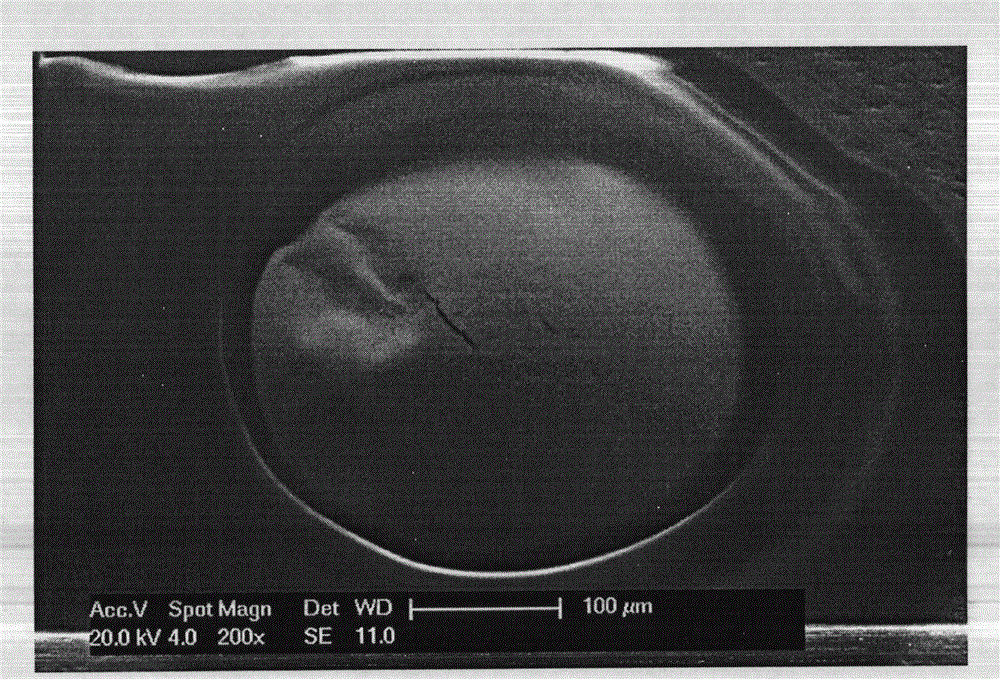

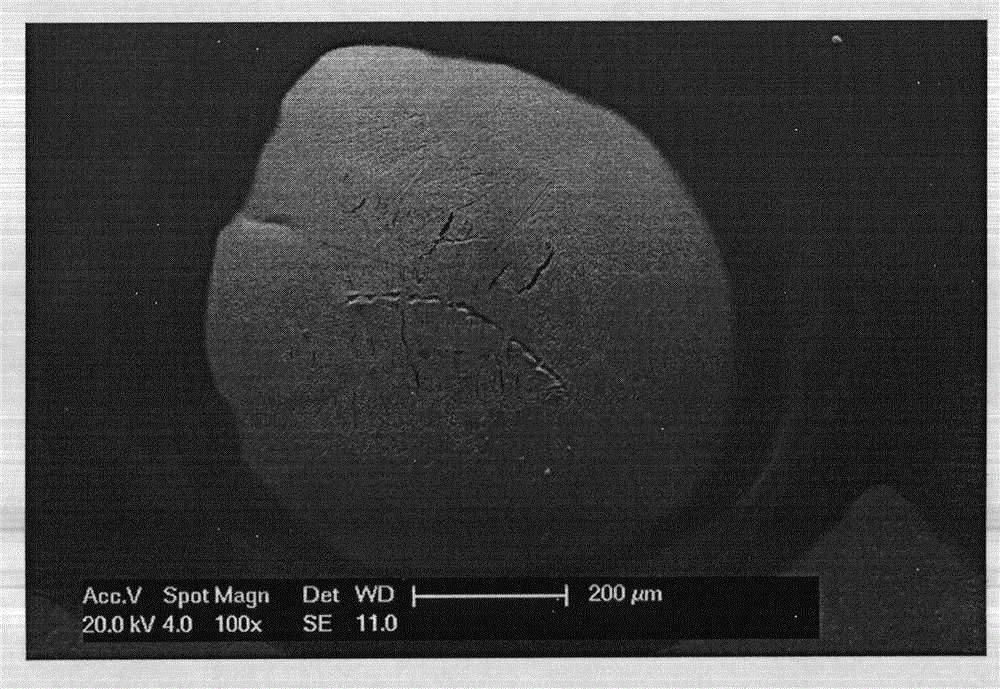

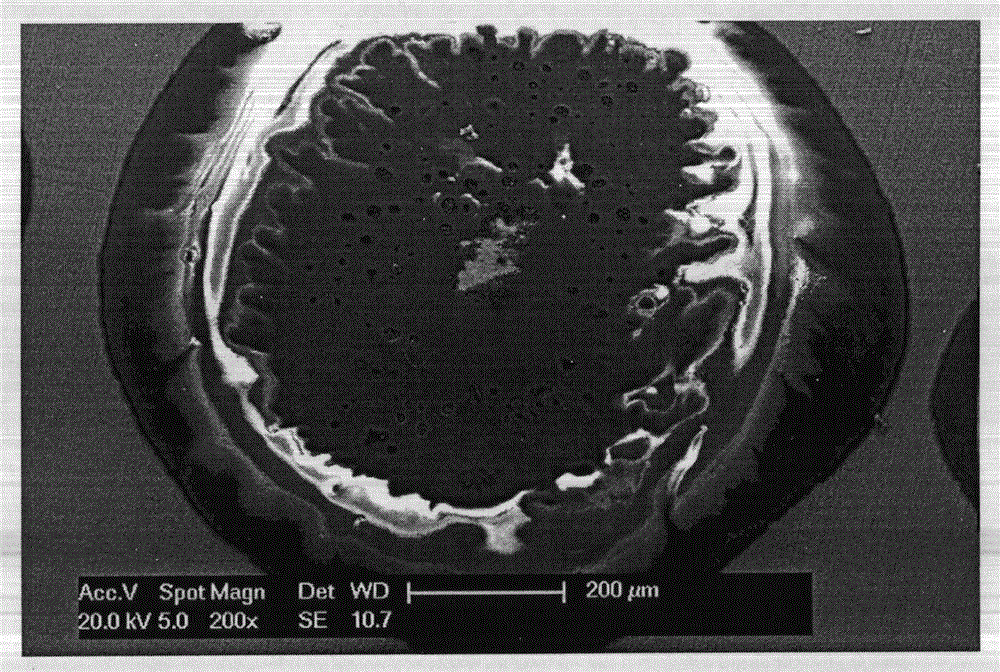

Image

Examples

Embodiment 1

[0032]

Embodiment 2

[0034]

[0035] Table 3 (comparative example)

[0036]

[0037] Can find out from the formula design of above embodiment 1 and embodiment 2 and comparative example:

[0038] ① As the part of rosin that imparts adhesive properties to the solder paste and prevents the re-oxidation of the PCB, the flux formulations of Examples 1 and 2 use fully hydrogenated rosin and / or polymerized rosin with a softening point lower than 110°C, while the traditional rosin in the comparative example The solder paste flux formula uses most of the high softening point acrylic modified rosin and a small part of low softening point hydrogenated rosin. The rosin system with low softening point endows the solder paste of the present invention in the reflow preheating process, and its flux has good flow characteristics; and in terms of rosin content, the rosin content of the flux formulations in Example 1 and Example 2 is 28% respectively And 25%, while the rosin content of the traditional formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com