Method for recovering zinc, silver and copper from zinc leaching residue

A zinc leaching slag, zinc-silver-copper technology, applied in the direction of process efficiency improvement, flotation, solid separation, etc., to achieve the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

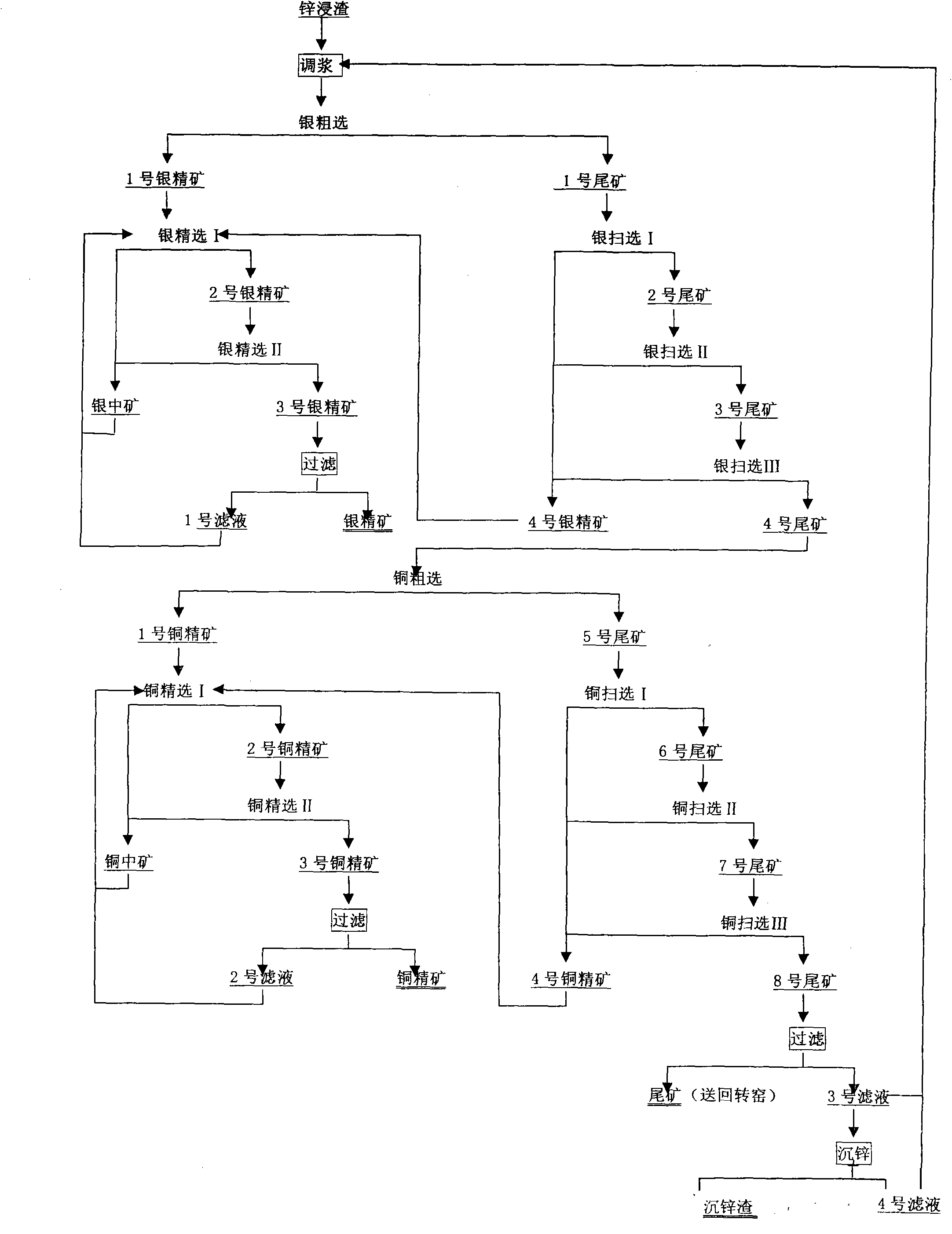

Method used

Image

Examples

Embodiment 1

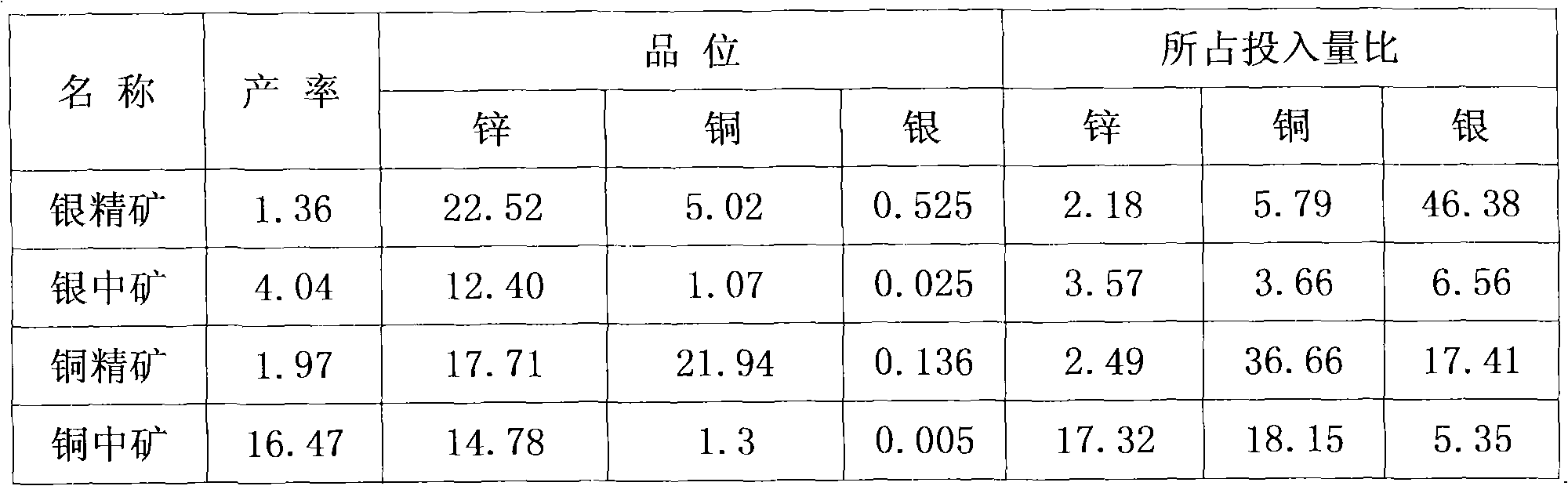

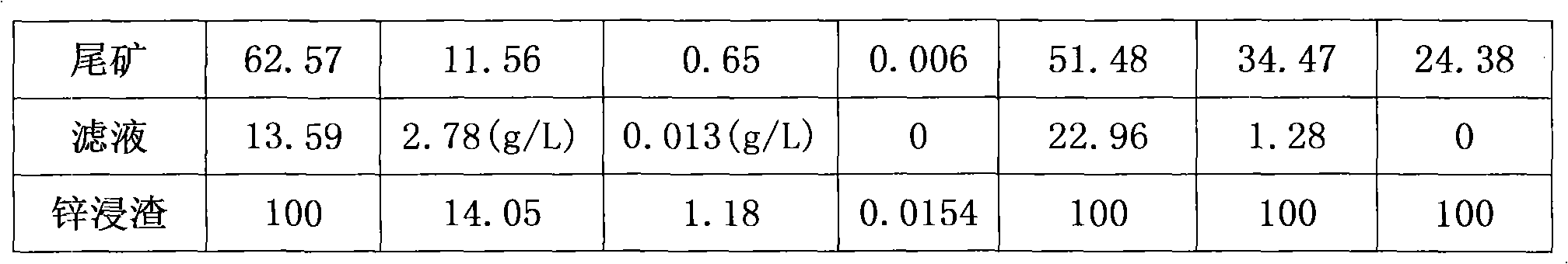

[0027]Example 1: 600g of zinc leaching slag containing 14.05wt% of zinc, 0.0154wt% of silver, 1.18wt% of copper and 22.58wt% of moisture after boiling and roasting and hydro-smelting zinc leaching with zinc concentrate is used as raw material, and water is adjusted The pulp concentration is 55wt%, adjust the pH to 4 with 98wt% sulfuric acid, and stir for 8 minutes; add 2g of sodium sulfite to prepare a 10wt% sodium sulfite aqueous solution, stir for 3 minutes, then add 0.4g of butylamine black medicine to prepare a 10wt% butyl Amine black chemical solution, stirred for 3 minutes, directly added No. 2 oil 0.025g, stirred for 2 minutes, opened the inflation valve, scraped and soaked for 10 minutes, and obtained No. 1 silver concentrate and No. 1 tailings. Adjust the No. 1 tailings to pH=4 with 98wt% sulfuric acid to carry out silver sweeping I, add 1.3g sodium sulfite, be mixed with 10wt% sodium sulfite aqueous solution, stir for 3min, add 0.25g of butylamine black medicine, be m...

Embodiment 2

[0039] Example 2: Zinc containing 11.79wt% of zinc, 0.0121wt% of silver, 0.93wt% of copper, and 28.00wt% of moisture from the zinc concentrate of Yunnan Luoping Zinc Electric Co., Ltd. leaching residue 550g, adjust the slurry concentration to 52wt% with water, adjust the pH to 4 with 98wt% sulfuric acid, stir for 8 minutes, add 2.5g of sodium sulfite to prepare a 10wt% sodium sulfite aqueous solution, stir for 3 minutes, then add 0.4g of butylamine black medicine, Prepare a 10wt% aqueous solution of butylamine black solution, stir for 3 minutes, directly add 0.03 g of No. 2 oil, stir for 2 minutes, open the inflation valve, and scrape and soak for 10 minutes to obtain No. 1 silver concentrate and No. 1 tailings. Then No. 1 tailings is adjusted to pH=4.5 with 98wt% sulfuric acid to carry out silver sweeping I, add 1.5g sodium sulfite, be mixed with 10wt% sodium sulfite aqueous solution, stir 5min, add butylamine black medicine 0.3g, be mixed with 10wt% Butylamine black chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com