Nano silver-copper oxide particle/graphene-based preparation method of non-enzyme electrochemical glucose sensor

A glucose sensor and nanoparticle technology, applied in the field of electrochemical analysis and detection, can solve the problems of limited sensing performance, poor stability, low conductivity, etc., and achieve the effects of high sensitivity, low cost, and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of an enzyme-free electrochemical glucose sensor based on nano silver-copper oxide particles / graphene, the preparation method is as follows:

[0031] (1) Configuration of silver-copper precursor solution: Weigh 4.689g copper nitrate and 0.085g silver nitrate (molar ratio is 50:1), add deionized water, stir and mix well, and prepare silver-copper precursor with 25mL volumetric flask body solution;

[0032] (2) Preparation of graphene oxide dispersion: disperse 40 mg of graphene oxide in 40 mL of deionized water, disperse ultrasonically for 2 h to obtain graphene oxide dispersion, and mix and stir with 1 mL of silver-copper precursor solution described in step (1) 30min (the content ratio of copper nitrate and graphene oxide is 0.001mol: 40mg);

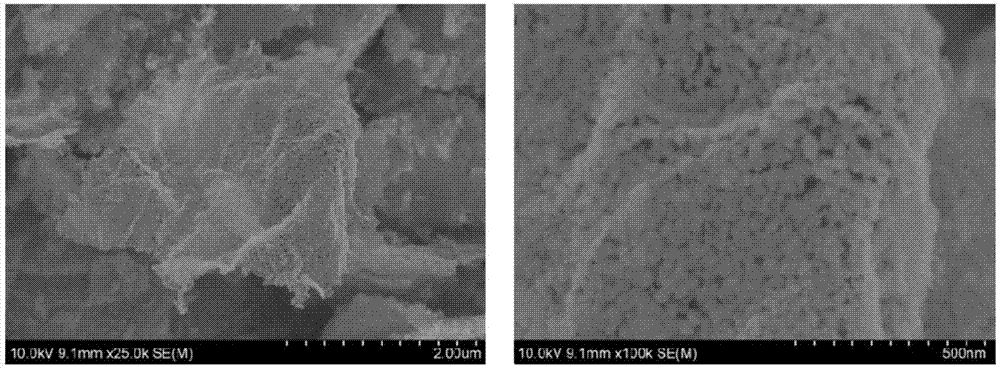

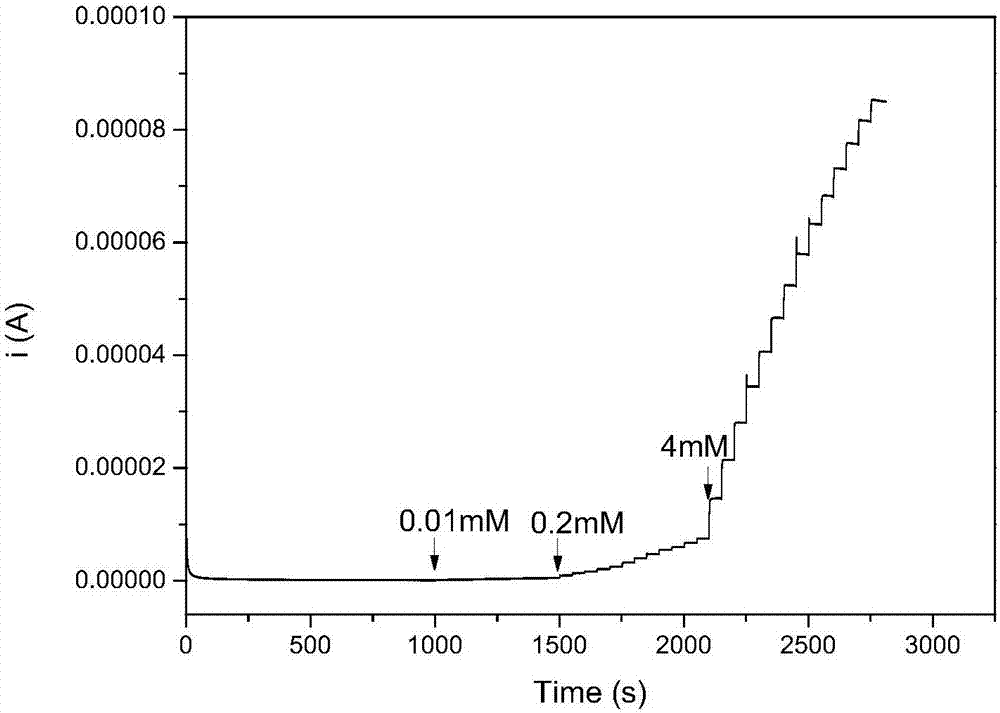

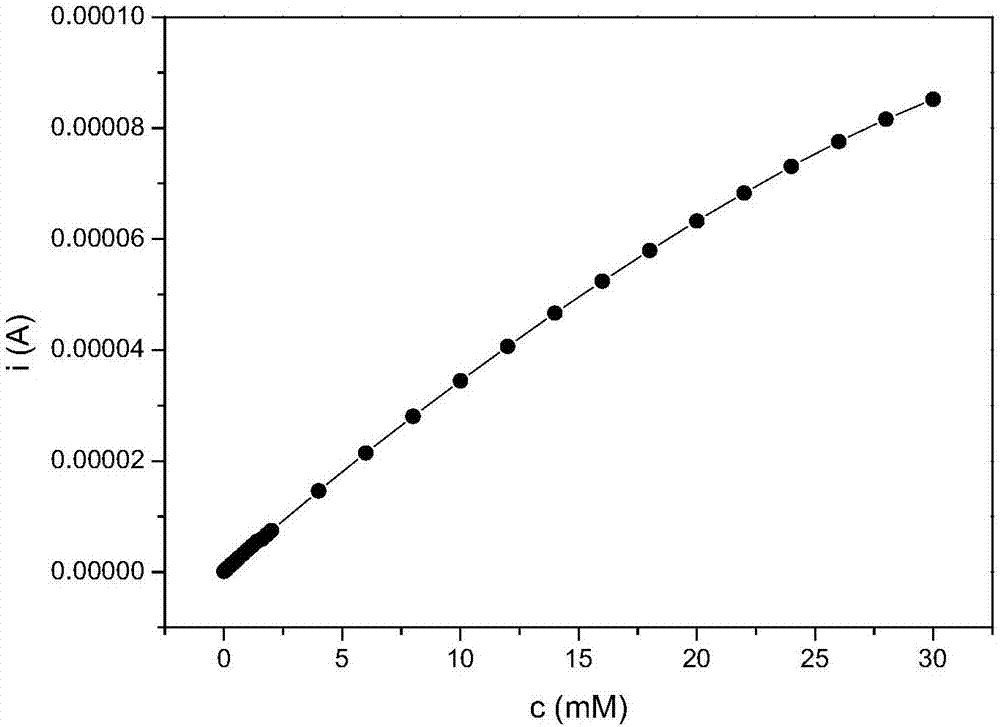

[0033] (3) Preparation of Ag-CuO nanoparticles / graphene suspension: After mixing the graphene oxide dispersion and the silver-copper precursor solution, add ammonia water to adjust the pH to about 10, stir f...

Embodiment 2

[0039] A preparation method of an enzyme-free electrochemical glucose sensor based on nano silver-copper oxide particles / graphene, the preparation method is as follows:

[0040](1) Configuration of silver-copper precursor solution: Weigh 9.378g of copper nitrate and 0.0425g of silver nitrate (molar ratio is 200:1), add deionized water, stir and mix, and prepare the silver-copper precursor with a 50mL volumetric flask body solution;

[0041] (2) Preparation of graphene oxide dispersion: disperse 10 mg of graphene oxide in 40 mL of deionized water, ultrasonically disperse for 2 h to obtain graphene oxide dispersion, and mix and stir with 2 mL of the silver-copper precursor solution described in step (1) 30min (the content ratio of copper nitrate and graphene oxide is 0.002mol: 10mg);

[0042] (3) Preparation of Ag-CuO nanoparticles / graphene suspension: After mixing the graphene oxide dispersion and the silver-copper precursor solution, add ammonia water to adjust the pH to abou...

Embodiment 3

[0046] A preparation method of an enzyme-free electrochemical glucose sensor based on nano silver-copper oxide particles / graphene, the preparation method is as follows:

[0047] (1) Configuration of silver-copper precursor solution: Weigh 4.689g of copper nitrate and 0.425g of silver nitrate (molar ratio is 10:1), add deionized water, stir and mix, and prepare silver-copper precursor with 25mL volumetric flask body solution;

[0048] (2) Preparation of graphene oxide dispersion: disperse 200mg graphene oxide in 40mL deionized water, ultrasonically disperse for 2h to obtain graphene oxide dispersion, mix and stir with 4mL silver-copper precursor solution described in step (1) for 30min (the content ratio of copper nitrate and graphene oxide is 0.004mol: 200mg);

[0049] (3) Preparation of Ag-CuO nanoparticles / graphene suspension: After mixing the graphene oxide dispersion and the silver-copper precursor solution, add ammonia water to adjust the pH to about 10, stir for 30 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com