Magnesium alloy semi-continuous casting process

A semi-continuous casting and magnesium alloy technology, applied in the field of magnesium alloy semi-continuous casting, can solve the problems of high raw material cost and poor elastic deformation resistance, and achieve improved die-casting performance and corrosion resistance, good elastic deformation resistance, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

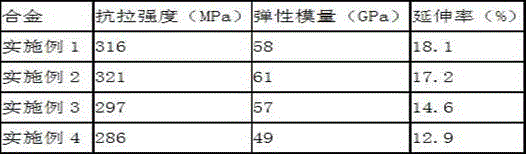

Examples

Embodiment 1

[0018] A magnesium alloy semi-continuous casting casting process, which includes the following steps: 1) material preparation, 2) preparation of material 1, 3) raw material preheating, 4) melting, 5) semi-continuous casting, 6) hot rolling and cold rolling, 7 )annealing.

[0019] Specifically, include the following steps:

[0020] 1) Raw material preparation: Weigh each raw material by weight for use: 1 part of neodymium, 1 part of niobium, 2 parts of zirconium, 3 parts of glass fiber, 8 parts of zinc, 10 parts of graphite, 15 parts of silicon, 20 parts of titanium, and 1000 parts of magnesium;

[0021] 2) Preparation of material 1: Add glass fiber and graphite to acetone in sequence, stir at 100 rpm for 6 hours, and then refrigerate at 4°C for 12 hours to obtain material 1; the mass ratio of acetone to graphite is 3:2 ;

[0022] 3) Raw material preheating: preheat neodymium, niobium, zirconium, zinc, silicon, titanium and magnesium at 200°C for 1 hour respectively;

[0023...

Embodiment 2

[0028] A magnesium alloy semi-continuous casting casting process, which includes the following steps: 1) material preparation, 2) preparation of material 1, 3) raw material preheating, 4) melting, 5) semi-continuous casting, 6) hot rolling and cold rolling, 7 )annealing.

[0029] Specifically, include the following steps:

[0030] 1) Raw material preparation: Weigh each raw material by weight for use: 2 parts of neodymium, 2 parts of niobium, 4 parts of zirconium, 5 parts of glass fiber, 12 parts of zinc, 15 parts of graphite, 20 parts of silicon, 30 parts of titanium, and 1300 parts of magnesium;

[0031] 2) Preparation of material 1: Add glass fiber and graphite to acetone in sequence, stir at 100 rpm for 6 hours, and then refrigerate at 4°C for 12 hours to obtain material 1; the mass ratio of acetone to graphite is 3:2 ;

[0032] 3) Raw material preheating: preheat neodymium, niobium, zirconium, zinc, silicon, titanium and magnesium at 200°C for 1 hour respectively;

[0...

Embodiment 3

[0038] The process steps are the same as in Example 1, except that graphite and glass fibers are not added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com