Waterborne epoxy/unsaturated polyester interpenetrating network polymer alloy and preparation method thereof

A water-based epoxy and interpenetrating network technology, which is applied in the field of water-based epoxy/unsaturated polyester polymer alloys and their preparation, and achieves the effects of excellent tensile strength, good application prospects, and excellent heat and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

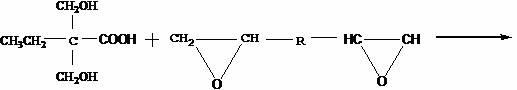

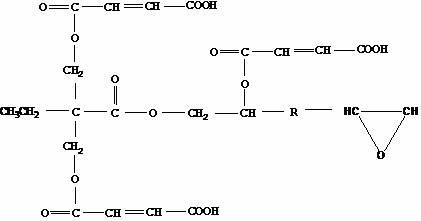

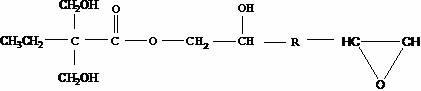

Method used

Image

Examples

Embodiment 1

[0049] Add 150Kg of bisphenol A type epoxy resin CYD-128 to a reaction kettle equipped with a stirrer, a condenser, a constant pressure feeding device and a thermometer, heat it to 70°C, and drop it with a constant pressure feeding device under stirring after constant temperature Add 25Kg of 2,2-dimethylolbutyric acid solution dissolved in N-methylpyrrolidone, add dropwise for half an hour, rise to 100°C, measure the acid value of the system regularly, stop the reaction when the acid value of the system is less than 5mgKOH / g , the product A is obtained by cooling;

[0050] Then, 50Kg of maleic anhydride was added, the temperature was raised to 130°C, and the acid value was measured every half an hour with concentrated sulfuric acid as a catalyst. When the acid value basically did not change, the reaction was stopped, and the product B was obtained by cooling down;

[0051] Finally, 13Kg of triethylamine was added therein as a neutralizing agent, reacted for 30min, slowly added...

Embodiment 2

[0057] Add 100Kg of bisphenol A type epoxy resin CYD-128 to a reaction kettle equipped with a stirrer, a condenser, a constant pressure feeding device and a thermometer, heat it to 70°C, and drop it with a constant pressure feeding device under stirring after constant temperature Add 25Kg of 2,2-dimethylolbutyric acid solution dissolved in N-methylpyrrolidone, add dropwise for half an hour, rise to 100°C, measure the acid value of the system regularly, stop the reaction when the acid value of the system is less than 5mgKOH / g , the product A is obtained by cooling;

[0058] Then put in 30Kg of maleic anhydride, heat up to 130°C, use concentrated sulfuric acid as a catalyst, measure the acid value every half an hour, stop the reaction when the acid value basically does not change, and cool down to obtain product B;

[0059] Finally, 13Kg of triethylamine was added therein as a neutralizing agent, reacted for 30 minutes, slowly added dropwise 250Kg of deionized water and stirred ...

Embodiment 3

[0065] Add 150Kg of bisphenol A type epoxy resin CYD-128 to a reaction kettle equipped with a stirrer, a condenser, a constant pressure feeding device and a thermometer, heat it to 70°C, and drop it with a constant pressure feeding device under stirring after constant temperature Add 25Kg of 2,2-dimethylolbutyric acid solution dissolved in N-methylpyrrolidone, add dropwise for half an hour, rise to 100°C, measure the acid value of the system regularly, stop the reaction when the acid value of the system is less than 5mgKOH / g , the product A is obtained by cooling;

[0066] Then, 40Kg of maleic anhydride was added, the temperature was raised to 130°C, and the acid value was measured every half an hour with concentrated sulfuric acid as a catalyst. When the acid value basically did not change, the reaction was stopped, and the product B was obtained by cooling down;

[0067] Finally, 13Kg of triethylamine was added therein as a neutralizing agent, reacted for 30 minutes, slowly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com