Preparation method of organosilicone adhesive

A technology of organic silica gel and adhesive, applied in the direction of adhesives, adhesive additives, epoxy resin glue, etc., can solve the problems of harsh production conditions, complicated production process, low production efficiency, etc., achieve high production efficiency, short preparation time, The effect of saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

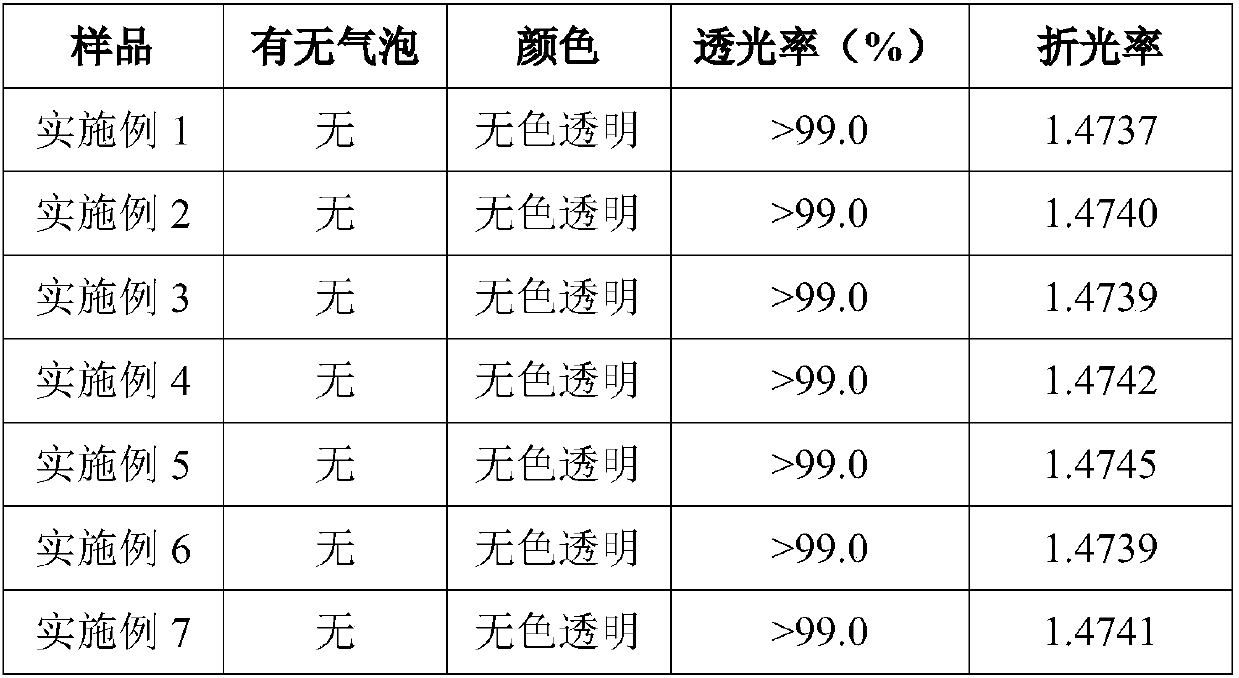

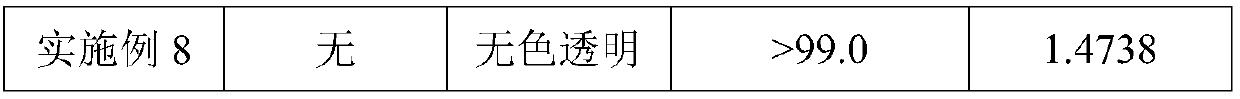

Examples

Embodiment 1

[0018] Preparation component A: weighed in parts by weight: 15 parts of epoxy resin compound o-cresol formaldehyde type polyepoxy resin, 10 parts of terminal vinylmethylphenyl polysiloxane of 900 cps, polyallyl compound 3 parts of ethylene glycol diallyl ether; add the weighed epoxy resin compound, 900cps terminal vinyl methyl phenyl polysiloxane and polyallyl compound into the first material cylinder of the mixer in sequence , start the mixer and stir for 30 minutes; the mixture obtained through stirring is filtered out from the first material tank through a 300-mesh filter screen at normal pressure, and enters the second material tank; the mixture filtered out at normal pressure is filled to obtain the composition Part A.

[0019] Preparation of component B: 25 parts by weight of 900 cps-terminated vinylmethylphenyl polysiloxane, 5 parts of liquid nitrile rubber as a toughening agent, 20 parts of terminal-group hydrogen-containing polysiloxane, containing platinum Catalyst:...

Embodiment 2

[0022] Preparation of component A: take by weight 16 parts of epoxy resin compound bisphenol A type epoxy resin, 20 parts of terminal vinylmethylphenyl polysiloxane of 1000cps, polyallyl compound butanediol 4 parts of diallyl ether; Add the epoxy resin compound, 1000cps terminal vinylmethylphenyl polysiloxane and polyallyl compound into the first material tank of the mixer in sequence, start the mixer Stir for 20 minutes; filter the stirred mixture from the first material tank through a 400-mesh filter at normal pressure, and enter the second material tank; fill the mixture filtered out at normal pressure to obtain component A.

[0023] Preparation of component B: 20 parts by weight of 1000 cps-terminated vinylmethylphenyl polysiloxane, 5 parts of toughening agent carboxyl liquid nitrile rubber, 23 parts of terminal-group hydrogen-containing polysiloxane, containing Platinum catalyst chloroplatinic acid tetramethyltetravinylcyclotetrasiloxane complex 0.015 parts; weighed 100...

Embodiment 3

[0026] Preparation of component A: Weigh 14 parts of epoxy resin compound polybutadiene resin, 15 parts of terminal vinylmethylphenyl polysiloxane of 800 cps, polyallyl compound hexadiol diene in parts by weight 2 parts of propyl ether; Add the weighed epoxy resin compound, 800cps terminal vinylmethylphenyl polysiloxane and polyallyl compound into the first material tank of the mixer in turn, start the mixer to stir 20 minutes; the mixture obtained by stirring is filtered out from the first material tank through a 400-mesh filter screen under normal pressure, and then enters the second material tank; the mixture filtered out under normal pressure is filled to obtain component A.

[0027] Preparation of component B: Weigh 25 parts by weight of 800 cps-terminated vinylmethylphenyl polysiloxane, 4 parts of toughening agent liquid silicone rubber, 25 parts of terminal-group hydrogen-containing polysiloxane and platinum-containing catalyst 0.016 part of chloroplatinic acid tetramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com