Antibacterial toughened polyethylene plastic processing technology

A technology of polyethylene plastic and processing technology, applied in the field of polyethylene plastic processing, can solve the problems of shortening the service life, high price, easy to move out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The modified antibacterial agent is made by the following steps:

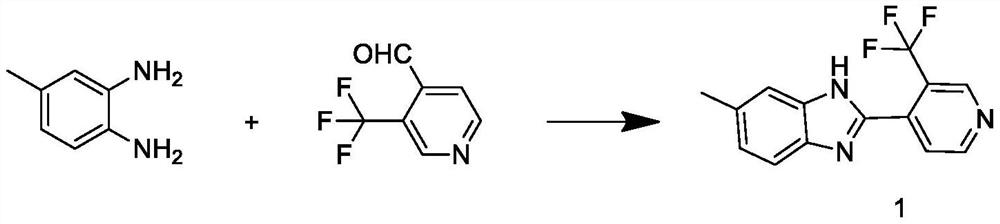

[0035] Step 1, add 0.1mol 4-methyl-o-phenylenediamine, 0.11mol 3-(trifluoromethyl)pyridine-4-carbaldehyde and 38mL DMF to the there-necked flask, stir for 5min under the condition of rotating speed 60r / min, be warming up to 100 ℃, add 5.2mL Na 2 S 2 O 5 The aqueous solution was heated to 130 °C, and the reaction was stirred for 30 min under the condition of a rotating speed of 100 r / min. After the reaction was completed, the reaction product was transferred to ice water, the product was precipitated, filtered with suction, and the filter cake was washed with deionized water 3 times, and then at 80 °C Dry to constant weight in an oven to obtain intermediate 1, Na 2 S 2 O 5 The aqueous solution consists of Na 2 S 2 O 5 Mixed with deionized water according to 0.58g: 5mL;

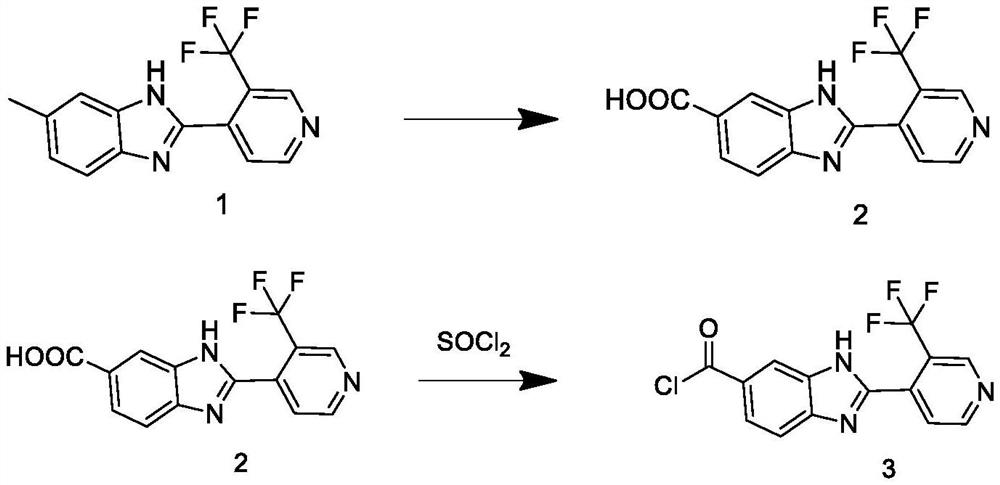

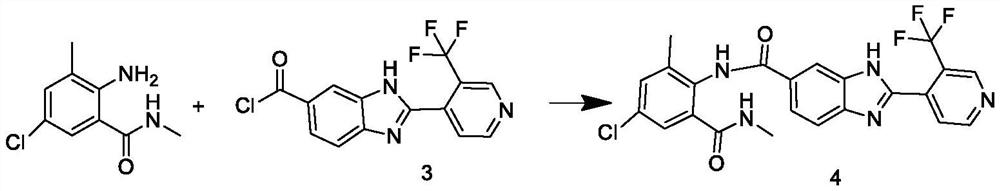

[0036] Step 2. Add 0.1 mol of intermediate 1 and 40 mL of DMF into a three-necked flask, add 0.2 g of potassium permanganate an...

Embodiment 2

[0041] The modified antibacterial agent is made by the following steps:

[0042] Step 1. Add 0.1mol 4-methyl-o-phenylenediamine, 0.11mol 3-(trifluoromethyl)pyridine-4-carbaldehyde and 40mL DMF to the there-necked flask, stir for 5min under the condition of rotating speed 70r / min, and heat up to 100 ℃, add 6.3mL Na 2 S 2 O 5 The aqueous solution was heated to 130 ° C, and the reaction was stirred for 40 min under the condition of rotating speed 150 r / min. After the reaction, the reaction product was transferred to ice water, the product was precipitated, suction filtration, and the filter cake was washed with deionized water for 4 times, and then at 80 ° C. Dry to constant weight in an oven to obtain intermediate 1, Na 2 S 2 O 5 The aqueous solution consists of Na 2 S 2 O 5 It is mixed with deionized water according to 0.88g: 5mL;

[0043] Step 2. Add 0.1mol of Intermediate 1 and 43mL of DMF into the three-necked flask, add 0.25g of potassium permanganate and 4.1mL of ...

Embodiment 3

[0048] The modified antibacterial agent is made by the following steps:

[0049] Step 1, add 0.1mol 4-methyl-o-phenylenediamine, 0.11mol 3-(trifluoromethyl)pyridine-4-carbaldehyde and 46mL DMF to the there-necked flask, stir for 5min under the condition of rotating speed 80r / min, be warming up to 100 ℃, add 8.4mL Na 2 S 2 O 5 The aqueous solution was heated to 130 °C, and the reaction was stirred for 50 min under the condition of a rotating speed of 200 r / min. After the reaction was completed, the reaction product was transferred to ice water, the product was precipitated, suction filtration, and the filter cake was washed with deionized water for 5 times, and then at 80 °C Dry to constant weight in an oven to obtain intermediate 1, Na 2 S 2 O 5 The aqueous solution consists of Na 2 S 2 O 5 Mixed with deionized water according to 0.12g: 5mL;

[0050] Step 2. Add 0.1 mol of intermediate 1 and 45 mL of DMF into a three-necked flask, add 0.3 g of potassium permanganate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com