Wire applied to LED lamp

A technology of LED lamps and wires, which is applied in the direction of conductors, insulated conductors, metal/alloy conductors, etc., can solve problems such as the decline in folding resistance, and achieve the effects of weight reduction, high electrical conductivity, and reduced wire quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

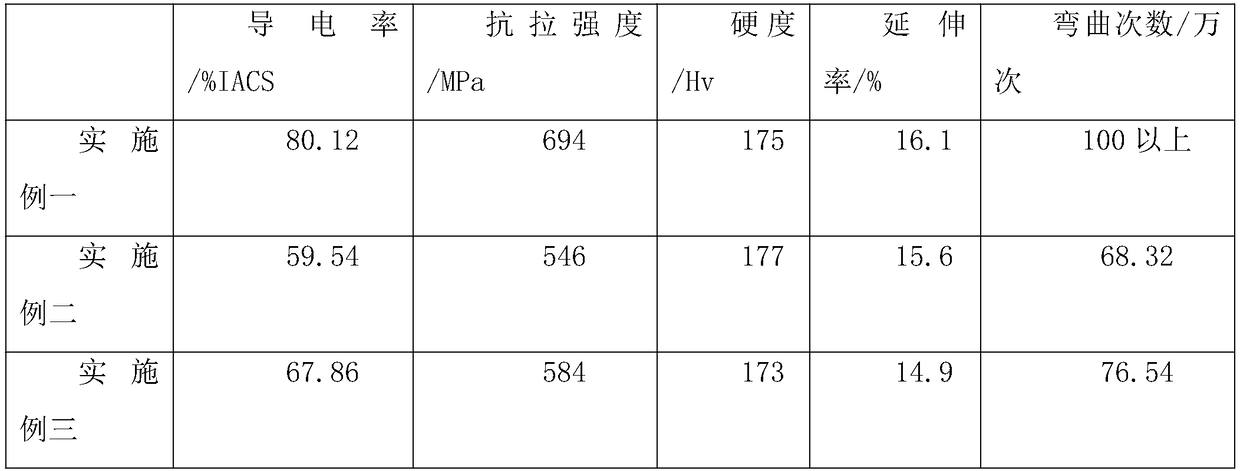

Examples

Embodiment 1

[0026] Embodiment 1: a wire for LED lamps, including a wire body and a protective shell. The protective casing includes an insulating layer, a fiber layer and a shell made of polyperfluoroethylene propylene. The fiber layer is a hollow tube formed by interweaving multiple fiber filaments, and the fiber layer is modified carbon fiber. The insulating layer is wrapped on the outer side of the copper alloy wire and located inside the fiber layer, and the outer shell made of polyfluoroethylene propylene is wrapped on the outer side of the fiber layer, and the insulating layer, the fiber layer and the polyfluoroethylene outer shell are integrally arranged.

[0027] The following is the processing flow of the wire:

[0028] 1. Put graphite into a crucible, place it in a muffle furnace for calcination, and under the protection of nitrogen, calcine at 700°C for 3 minutes, take it out, and crush it into powder to obtain material 1;

[0029] 2. Add material 1, carbon fiber and nano sili...

Embodiment 2

[0041] Embodiment two: the difference from embodiment one is that the weight percentage of each component is: Cr0.1%, Zr0.3%, Si0.2%, Ag4%, Hf0.06%, Zn0.8% , Fe2%, Au0.8%.

Embodiment 3

[0042] Embodiment three: the difference from embodiment one is that the weight percentage of each component is: Cr0.7%, Zr0.005%, Si0.005%, Ag4%, Hf0.4%, Zn0.8% , Fe2%, Au0.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com