High-permeability polyurethane graft-modified epoxy resin interpenetrating-network polymer grouting material and preparation method thereof

A technology of epoxy resin and graft modification, which is applied in the direction of educts, products, reagents, etc., can solve the problems of limited modification effect, poor environmental protection, and difficult to meet the tensile strength, so as to improve the moisture curing rate, The effect of solving curing difficulties and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

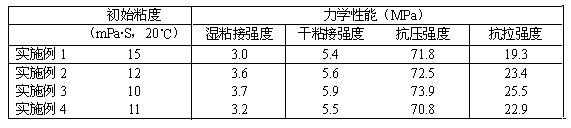

Embodiment 1

[0048] Raw material pretreatment: put epoxy resin and polyethylene glycol in a vacuum drying oven, dry in vacuum at 110-120° C. for 4 hours, and cool to room temperature for later use.

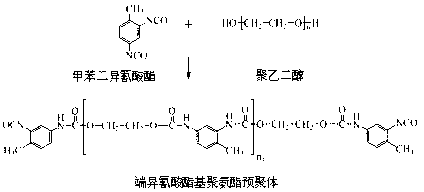

[0049] Synthesis of isocyanate-terminated polyurethane prepolymer (PU-prepolymer): Add 100 g PEG1000 into a four-necked flask equipped with a stirrer, thermometer, Y-shaped dropping funnel, and reflux condenser, and heat up to 50 °C under slow stirring. ℃, under the protection of nitrogen, add 34.8 g TDI dropwise (dropping within 30 minutes), raise the temperature to 60℃, and react for 1-3 hours to obtain the isocyanate-terminated PU-prepolymer.

[0050] (1) Preparation of component A:

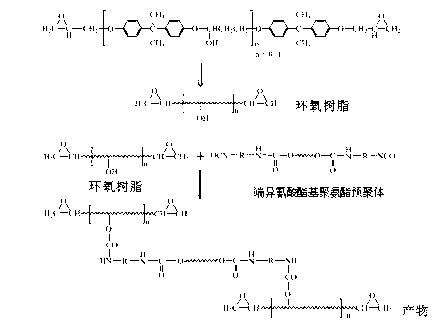

[0051] Mix the isocyanate-terminated polyurethane prepolymer and epoxy resin in a mass ratio of 5:95, heat up to 70°C under stirring, react under nitrogen protection, and sample -NCO groups every hour until all of them disappear, stop reaction to obtain the intermediate; mix 100 parts of the above intermediat...

Embodiment 2

[0056] The synthesis of the isocyanate-terminated (-NCO) polyurethane (PU) prepolymer is the same as step (1) of Example 1.

[0057] The preparation of the isocyanate-based polyurethane prepolymer is compared with Example 1, except that the mass ratio between the isocyanate-based polyurethane prepolymer and the epoxy resin is changed to 10:90, and the others are the same.

[0058] The preparation of the intermediate (grafted PU / EP IPNs) is the same as in Example 1;

[0059] Component A: 100 parts of synthetic grafted PU / EP IPNs, 20 parts of diluent I (composed of 10 parts of butyl glycidyl ether, 5 parts of ethylene glycol diglycidyl ether and 5 parts of 1,6-hexanediol diol Glycidyl ether is uniformly mixed), 1 part of simethicone antifoaming agent is mixed, stirred evenly, and component A is obtained.

[0060] Component B: 45 parts of curing agent (composed of 25 parts of diethylenetriamine, 15 parts of triethylenetetramine and 5 parts of isophoronediamine), 20 parts of dilu...

Embodiment 3

[0063] The synthesis of the isocyanate-terminated (-NCO) polyurethane (PU) prepolymer is the same as step (1) of Example 1.

[0064] The preparation of the isocyanate-based polyurethane prepolymer is compared with Example 1, except that the mass ratio between the isocyanate-based polyurethane prepolymer and the epoxy resin is changed to 15:85, and the others are the same.

[0065] The preparation of the intermediate (grafted PU / EP IPNs) is the same as in Example 1;

[0066] Component A: 100 parts of synthetic grafted PU / EP IPNs, 20 parts of diluent I (composed of 5 parts of butyl glycidyl ether, 5 parts of ethylene glycol diglycidyl ether, 5 parts of 1,6-hexanediol diol Glycidyl ether and 5 parts of phenyl glycidyl ether are uniformly mixed), and 1 part of simethicone antifoaming agent is mixed and stirred evenly to obtain component A.

[0067] Component B: 45 parts of curing agent (composed of 20 parts of diethylenetriamine, 20 parts of triethylenetetramine and 5 parts of is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com