Rapid phosphating agent for galvanized steel sheets for color coating and application thereof

A technology of galvanized steel sheet and phosphating agent, which is applied in the coating process of metal materials, etc., can solve the problems of short processing time and inability to meet the pre-treatment production requirements of color-coated steel sheets, and achieve short processing time, superior performance, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

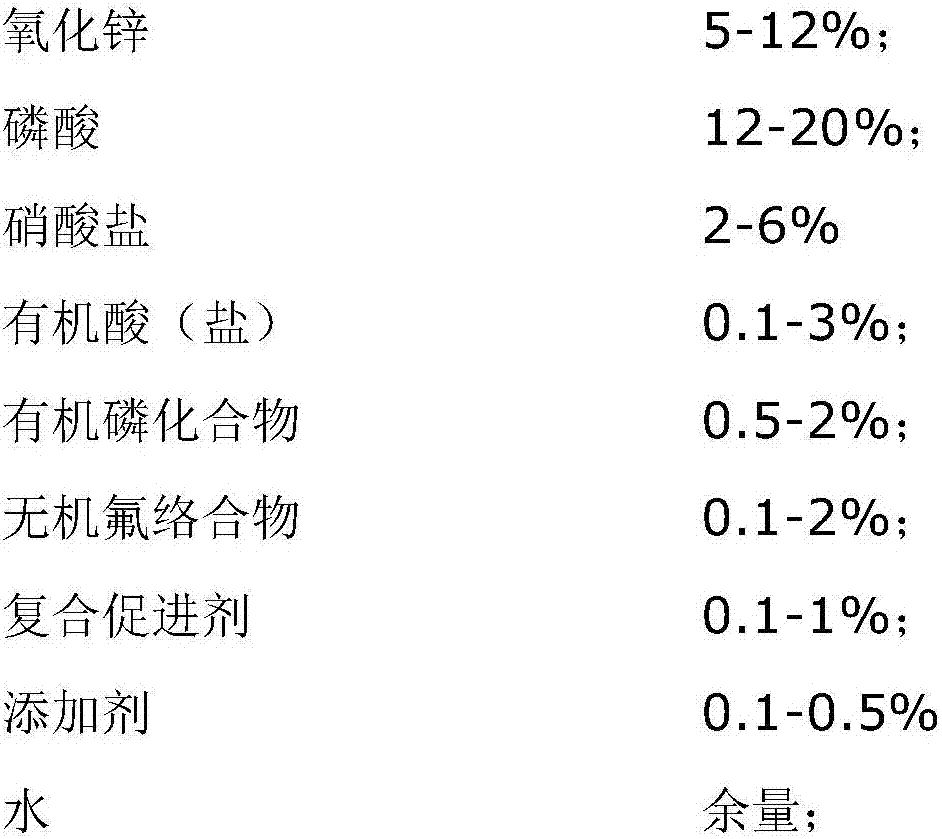

[0027] The preparation and application of the rapid phosphating agent for electro-galvanized steel sheet for color coating is characterized in that: the mass percentage of each component of the raw material is:

[0028]

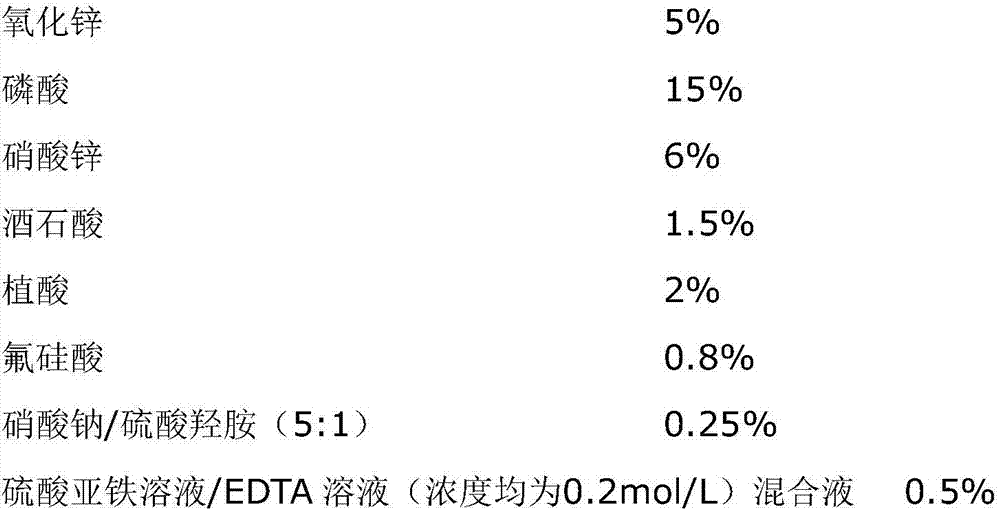

[0029]

[0030] The preparation method of described rapid phosphating solution comprises the steps:

[0031] (1) add phosphoric acid in reactor, open reactor and stir;

[0032] (2) Add 40-50% of the total amount of water required in the reactor;

[0033] (3) Add slurry-like zinc oxide adjusted with a small amount of water in advance into the reactor, and stir to make it completely dissolve;

[0034] (4) Add to 80-90% of the total amount of water required in the reactor;

[0035] (5) Add zinc nitrate, tartaric acid, phytic acid, fluosilicic acid, sodium nitrate / hydroxylamine sulfate (5:1 mixture) into the reaction kettle respectively, stir evenly to mix thoroughly;

[0036] (6) Add ferrous sulfate solution and EDTA solution (concentration is 0.2mol / L)...

Embodiment 2

[0042] The preparation and application of the rapid phosphating agent for electro-galvanized steel sheet for color coating is characterized in that: the mass percentage of each component of the raw material is:

[0043]

[0044]

[0045] The preparation method step of described fast phosphating solution is the same as embodiment 1.

[0046] The rapid phosphating solution is used for the rapid phosphating treatment of color-coated galvanized steel sheets at a temperature of 35°C, a pH of 2.5, and a time of 6 seconds, and is treated by roller coating. The treated electro-galvanized substrate has been tested, and the phosphating film is uniform, fine, smooth and without exposed bottom, the brightness is 87%, and no red rust appears in the neutral salt spray test for 48 hours, which meets the technical requirements of the product.

Embodiment 3

[0048] The preparation and application of the fast phosphating agent for hot-dip galvanized steel sheet for color coating is characterized in that: the mass percentage of each component of the raw material is:

[0049]

[0050] The preparation method step of described fast phosphating solution is the same as embodiment 1.

[0051] The rapid phosphating solution is used for the rapid phosphating treatment of the hot-dip galvanized steel sheet for color coating. The temperature is 20°C, the pH is 2.8, and the time is 8 seconds. Roller coating is used for treatment. The treated hot-dip galvanized base material has been tested, and the phosphating film is uniform, fine, smooth and without exposed bottom, and no red rust appears in the neutral salt spray test for 72 hours, which meets the technical requirements of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com