Method for preparing macromolecular nano composite membrane enriching inorganic filler on surface

An inorganic filler and nanocomposite technology, which is applied in the field of preparing polymer nanocomposite membranes enriched with inorganic fillers on the surface, can solve undiscovered problems and achieve the effect of promoting volatilization and improving film formation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

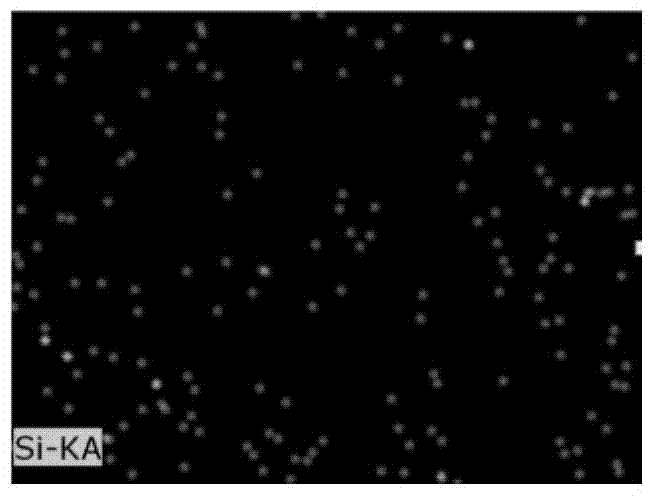

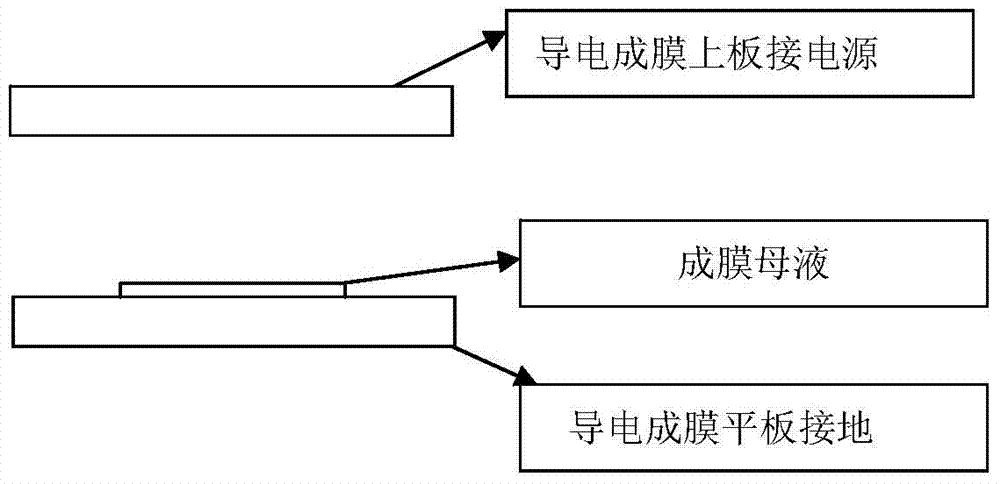

[0031] 0.5 g of nylon 6 with a molecular weight of 10,000 g / mol was dissolved in 10 ml of formic acid, and then 0.1 g of polysilsesquioxane was added to obtain a film-forming mother liquor. Place 5ml of the film-forming mother solution on the conductive film-forming plate, place the film-forming plate in the parallel plate electric field, and apply an electric field on both sides of the watch glass, wherein the conductive film-forming upper plate is negatively charged, the conductive film-forming plate is grounded, and the DC voltage field Strong is 1000V. The schematic diagram of the film forming device is as follows image 3 shown. At room temperature, the film-forming liquid was completely phase-separated for 40 min under the action of an electric field, and an organic-inorganic composite film was obtained. The energy spectrum analysis of the composite material shows that the surface Si content is 0.54wt%, and the Si element distribution diagram is as follows Figure 4 s...

Embodiment 2

[0035] 0.5 g of nylon 6 with a molecular weight of 10,000 g / mol was dissolved in 10 ml of formic acid, followed by the addition of NaYF 4 0.1 g to obtain a film-forming mother liquor. Put 5ml of the film-forming mother solution on the conductive film-forming plate, place the film-forming plate in the parallel plate electric field, and apply an electric field on both sides of the watch glass, wherein the conductive film-forming upper plate is negatively charged, the conductive film-forming plate is grounded, and the DC voltage field The strength is 2000V. The schematic diagram of the film forming device is as follows image 3 shown. At room temperature, the film-forming liquid was completely phase-separated for 40 min under the action of an electric field, and an organic-inorganic composite film was obtained. The energy spectrum analysis of the composite material shows that the surface Na content is 0.39wt%, and the Na element distribution is as follows Figure 8 shown. N...

Embodiment 3

[0037] 0.5 g of nylon 6 with a molecular weight of 10,000 g / mol was dissolved in 10 ml of formic acid, and then 0.1 g of polysilsesquioxane was added to obtain a film-forming mother liquor. Place 5ml of the film-forming mother solution on a conductive film-forming plate, place the film-forming plate in a parallel plate electric field, and apply an electric field on both sides of the watch glass, wherein the upper plate is negatively charged, the lower plate is grounded, and the DC voltage field strength is 4000V. The schematic diagram of the film forming device is as follows image 3 shown. At room temperature, the film-forming liquid was completely phase-separated for 40 min under the action of an electric field, and an organic-inorganic composite film was obtained. The composite material was analyzed by energy spectrum, and the surface Si content was 0.44wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

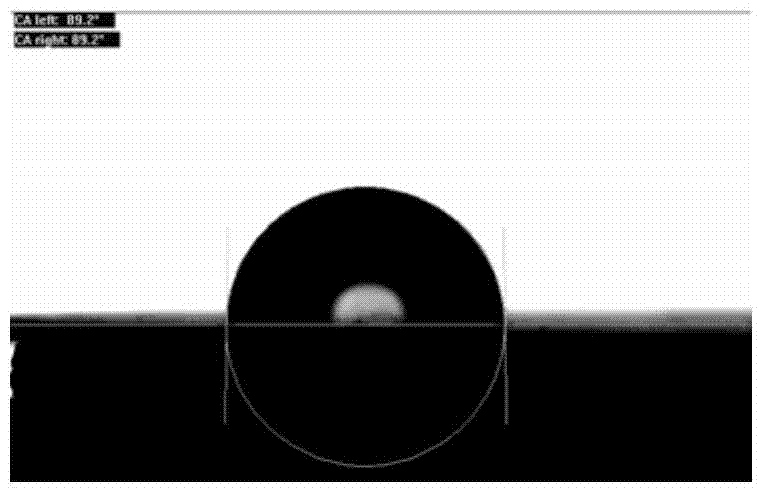

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com