Method for controlling micro-arc oxidation electricity parameters under peak current output mode

A technology of micro-arc oxidation and control method, which is applied in the field of surface engineering, can solve the problems of low processing efficiency, excessive process energy consumption, high processing cost, etc., and achieve the effects of reducing heat loss, improving film forming efficiency, and improving energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

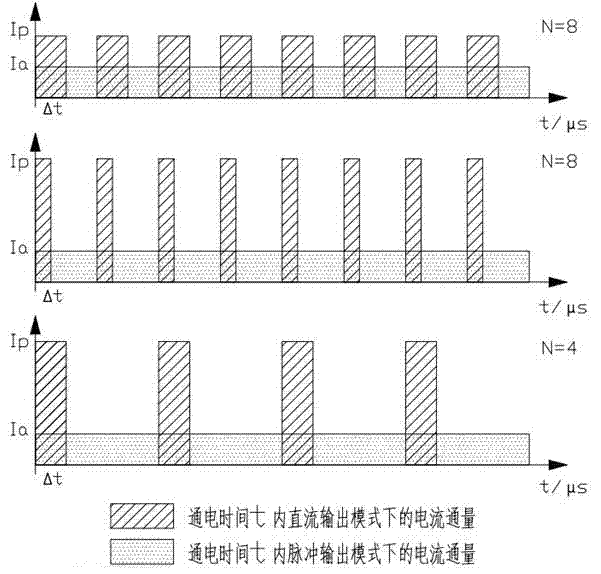

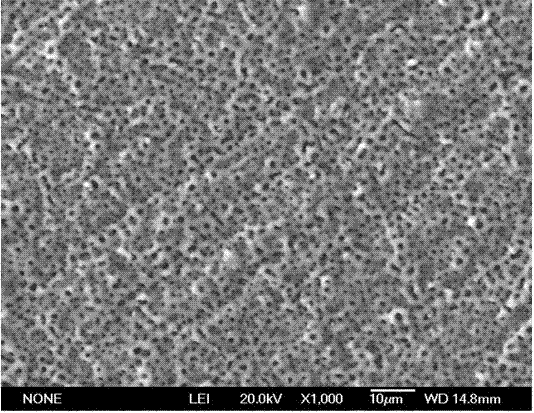

[0028] Set the area to 1dm 2 The AZ31 magnesium alloy samples were polished with 400#, 800# and 1200# water sandpaper from coarse to fine, successively washed with tap water, distilled water and absolute ethanol, and then dried with hot air; As the anode and the stainless steel as the cathode, after connecting to the output port of the DC pulse power supply respectively, the magnesium alloy is immersed in the silicate system electrolyte for micro-arc oxidation treatment. The silicate system electrolyte is composed of silicic acid Sodium 5g / L, potassium hydroxide 11g / L and potassium fluoride 7g / L, the solvent is distilled water; first set the initial electrical parameters on the micro-arc oxidation power supply (model MAO-15 / 1500): Ip 1 =400A / dm 2 , Δt 1 =10us, N 1 =500, then start the power supply and last for t 1 =30s, after energizing for 20s, a uniform arc discharge phenomenon appears on the surface of the pretreatment part, and at the same time the surface ceramic laye...

Embodiment 2

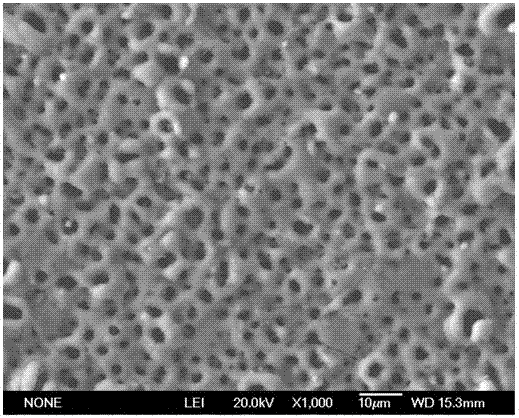

[0032] Set the area to 1dm 2 The LY12 aluminum alloy samples were polished with 400#, 800# and 1200# water sandpaper from coarse to fine, successively washed with tap water, distilled water and absolute ethanol, and then dried with hot air; As the anode and the stainless steel as the cathode, after connecting to the output port of the DC pulse power supply respectively, the aluminum alloy is immersed in the electrolyte of the silicate system for micro-arc oxidation treatment. The electrolyte of the silicate system is composed of silicic acid Sodium 15g / L, potassium hydroxide 5g / L and sodium hexametaphosphate 10g / L, the solvent is distilled water; first set the initial electrical parameters on the micro-arc oxidation power supply (model MAO-15 / 1500): Ip 1 =600A / dm 2 , Δt 1 =20us,N 1 =500, then start the power supply and last for t 1 = 30s, 27s after electrification, uniform arc discharge phenomenon appears on the surface of the pretreatment part, and at the same time the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com