Waterproof alkali-resistant seal primer for external walls

A technology of sealing primer and alkali-resistant primer, applied in the direction of coating, etc., can solve the problems of affecting the appearance of the main coating film of the base material protection coating, affecting the comprehensive performance of the base-level insulation system, and poor waterproof performance of the primer, achieving excellent coating performance. Membrane quality, good water resistance, excellent water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

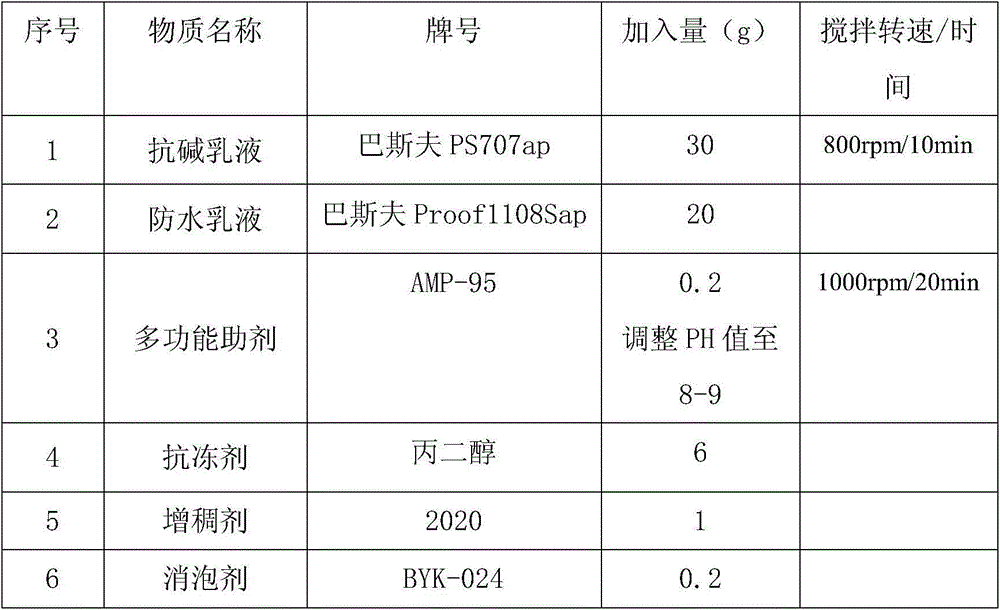

[0022] The waterproof and alkali-resistant sealing primer for exterior walls is weighed according to the raw material ratio in Table 1. First, add the anti-alkali emulsion and waterproof emulsion into the stainless steel emulsification tank, and disperse at a high speed of 800rpm for 10 minutes; then add multifunctional additives, antifreeze, Thickener, defoamer, wetting agent and bactericidal preservative are dispersed at a speed of 1000rpm for 20 minutes at a high speed; finally, film-forming aids and water are added and dispersed at a speed of 600rpm for 10 minutes to obtain a waterproof and alkali-resistant closed bottom of the outer wall Lacquer finished.

[0023] Table 1 - Raw material ratio of exterior wall waterproof and alkali-resistant sealing primer

[0024]

[0025]

Embodiment 2

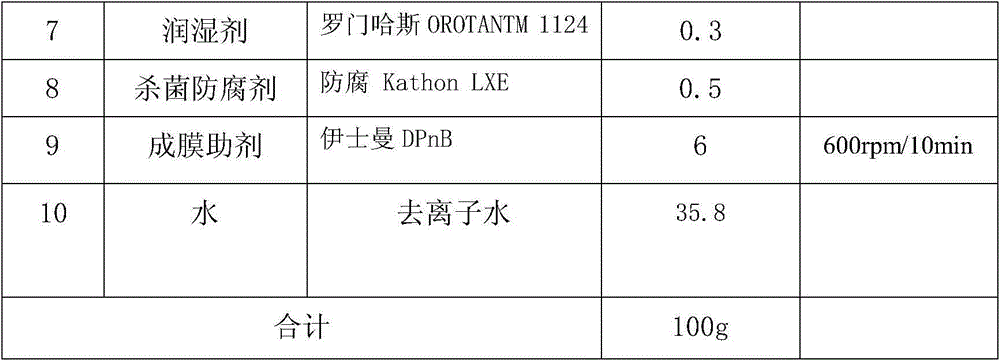

[0027] The difference between the preparation process of the waterproof and alkali-resistant sealing primer for exterior walls and that of Example 1 is that the waterproof and alkali-resistant sealing primer for exterior walls is made according to the ratio of raw materials in Table 2.

[0028] Table 2 - Raw material ratio of exterior wall waterproof and alkali-resistant sealing primer

[0029]

Embodiment 3

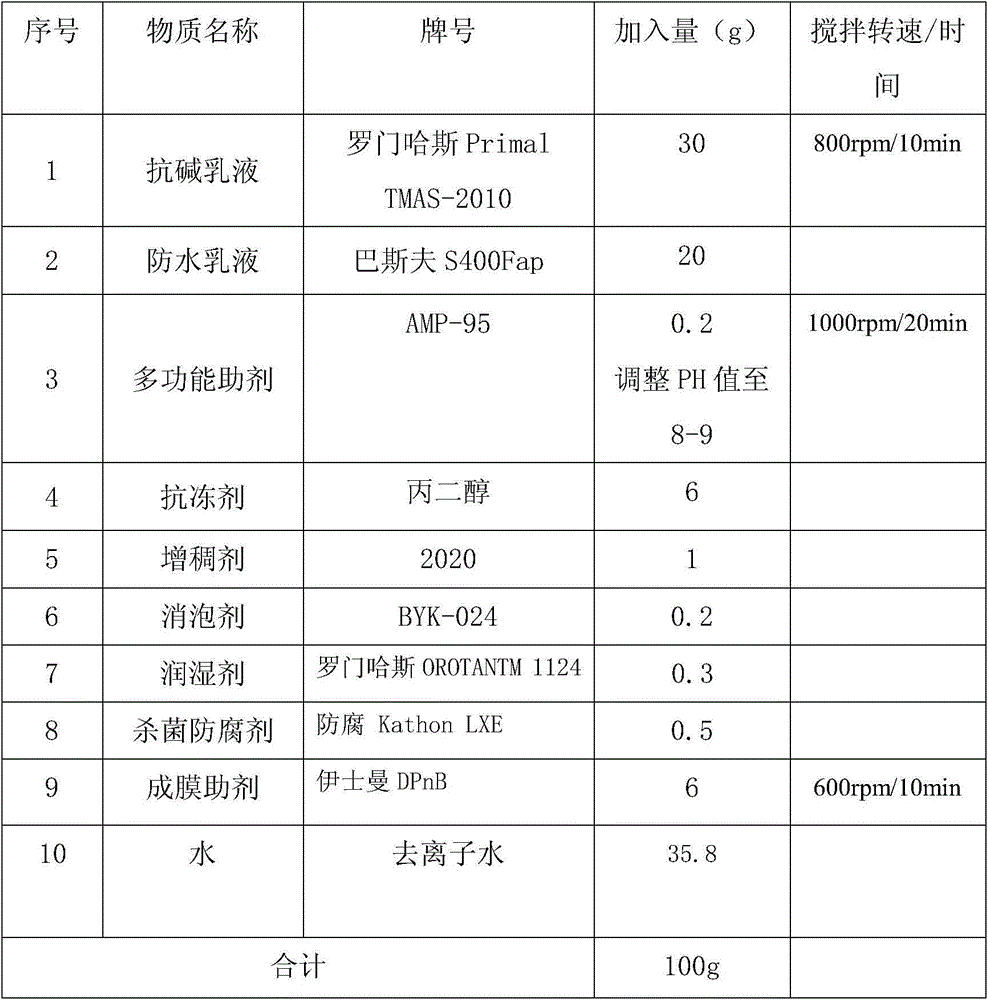

[0031] The difference between the preparation process of the exterior wall waterproof and alkali-resistant sealing primer and that of Example 1 is that the exterior wall waterproof and alkali-resistant sealing primer is made according to the ratio of raw materials in Table 3

[0032] Table 3 - Raw material ratio of exterior wall waterproof and alkali-resistant sealing primer

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com