Preparation method of defoaming agent with good stability

A defoamer and stability technology, applied in the field of defoamer preparation, can solve problems such as unstable quality and poor defoaming treatment effect, improve the preparation method, increase the specific surface area and adsorption capacity, and increase the utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

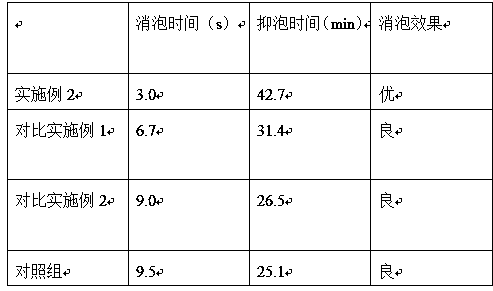

Examples

Embodiment 1

[0030] A kind of preparation method of good defoamer of stability, comprises the steps:

[0031] (1) Preparation of defoaming functional additives:

[0032] a. First put the crop straw into the pulverizer for pulverization, and then take out the pulverized straw for later use;

[0033] b. Put the crushed straw obtained in operation a into a steam explosion tank for steam explosion treatment, and take it out for later use after completion;

[0034] c. Put the attapulgite into the calcination furnace for calcination, and take it out after 1 hour for later use;

[0035] d. Put starch and water into the reactor according to the weight ratio of 1:6, heat to keep the temperature in the reactor at 78°C, stir continuously for 42 minutes, then add 1% of the total mass to the reactor dropwise After the phosphoric acid solution was continuously stirred for 1.2 hours, it was taken out and poured into ethanol for precipitation, then rinsed with deionized water, then vacuum filtered and d...

Embodiment 2

[0052] A kind of preparation method of good defoamer of stability, comprises the steps:

[0053] (1) Preparation of defoaming functional additives:

[0054] a. First put the crop straw into the pulverizer for pulverization, and then take out the pulverized straw for later use;

[0055]b. Put the crushed straw obtained in operation a into a steam explosion tank for steam explosion treatment, and take it out for later use after completion;

[0056] c. Put the attapulgite into the calcination furnace for calcination treatment, take it out after 1.5h for later use;

[0057] d. Mix starch and water into the reactor according to the weight ratio of 1:6.6, heat to keep the temperature in the reactor at 80°C, and stir continuously for 44 minutes, then add 1.3% of its total mass dropwise into the reactor After the phosphoric acid solution was continuously stirred for 1.4 hours, it was taken out and poured into ethanol to precipitate, then rinsed with deionized water, and then vacuum ...

Embodiment 3

[0074] A kind of preparation method of good defoamer of stability, comprises the steps:

[0075] (1) Preparation of defoaming functional additives:

[0076] a. First put the crop straw into the pulverizer for pulverization, and then take out the pulverized straw for later use;

[0077] b. Put the crushed straw obtained in operation a into a steam explosion tank for steam explosion treatment, and take it out for later use after completion;

[0078] c. Put the attapulgite into the calcination furnace for calcination, and take it out after 2 hours for later use;

[0079] d. Put starch and water into the reactor according to the weight ratio of 1:7, heat to keep the temperature in the reactor at 83°C, stir continuously for 46 minutes, then add 1.5% of the total mass to the reactor dropwise After the phosphoric acid solution was continuously stirred for 1.6 hours, it was taken out and poured into ethanol to precipitate, then rinsed with deionized water, and then vacuum filtered a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com